Solvex™ Filters: 0.2 µm sterilizing PTFE membrane for non-aqueous solutions Selecting the right filter Choosing the right sterilizing filter and device format for the process step or application is key to developing an efficient, cost-effective process.

Hydrophobic sterilizing-grade filters are commonly used as air vents on processing tanks. The goal of the application is to maintain near ambient pressure in the tank while ensuring sterility. The tank vent filter removes viruses and microorganisms from the gas as it flows in or out of the tank.

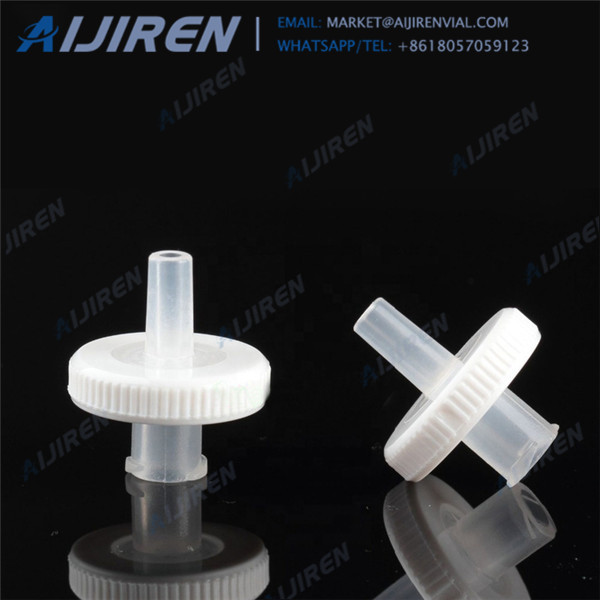

Nalgene™ 50mm inline filter with PTFE membrane provides an excellent barrier for sterile venting of benchtop fermentors, in-line gas filtration, or protecting vacuum pumps from moisture. It also gives the ability to filter aggressive chemicals, including acids and non-aqueous solvents, such as those used in GC and HPLC. Autoclavable

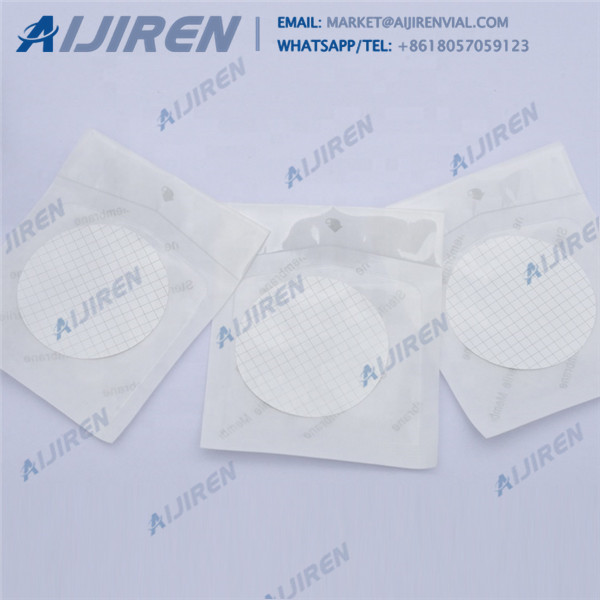

May 21, 2019 · 50MM PTFE MAIN APPLICATION: Naturally hydrophobic PTFE membrane provides the best chemical resistance, and can be used forventing applications or filtering gases , individually wrapped filters. 50MM PTFE MAIN FEATURES: 100% integritytested , sterile, and certified nonpyrogenic and noncytotoxic.

The ptfe 50mm Acrodisc hydrophobic filter with hose barbs can be used to sterilize non-aqueous solutions, vacuum line protection, venting and gas filtration. Hose barb end allows easy secure attachment of silicone tubing or other types of tubing. The filter is non sterile and is autoclavable. Do not.

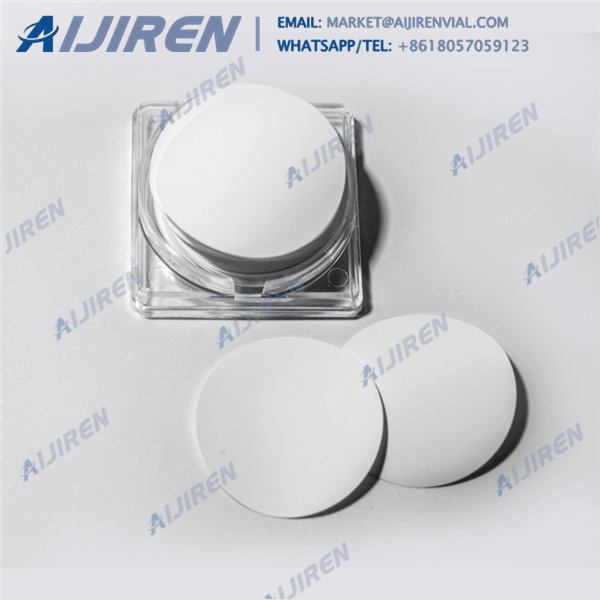

GVWP02500 Millipore Durapore® Membrane Filter, 0.22 µm Download Zoom 0.22 µm pore size, hydrophilic PVDF, 25 mm membrane Durapore® Membrane Filter, 0.22 µm MSDS (material safety data sheet) or SDS, CoA and CoQ, dossiers, brochures and other available documents. SDS View Products on Sigmaaldrich.com GVWP02500

Supplier: Pall Laboratory. Reusable, in-line filters with 50 mm hydrophobic PTFE membranes in polypropylene housing. Reusable. Hydrophobic. Polypropylene housing. Large surface area provides greater throughput. Ideal for venting bioreactors, fermentation tanks, and carboys. Also for filtration of aggressive solvents and sterile gas purging of

Aerex ® cartridge filters contain 0.2 μm polytetrafluoroethylene (PTFE) membrane and are designed for the removal of bacteria and viruses from moist gas streams in moderately- or non-critical applications. Aerex ® filters are not validated for bacterial retention.

A 0.22 µm pore size non-sterile filter validated for air monitoring. With biologically inert mixtures of cellulose acetate & cellulose nitrate, MF-Millipore membranes are widely used in analytical & research applications.

Description; Catalogue Number: SLGP05010: Trade Name: Millex ®; Description: Millex-GP Filter, 0.22 µm: Background Information: Millex® syringe filter units with hydrophobic Fluoropore™ or Millipore Express® PLUS PES membrane are ideal for in-line sterilization of gases and venting sterile containers, and filters with Fluoropore™ membrane can also be used for sterilizing or clarifying

Vent filters can provide a sterile barrier for air or gases entering or exiting vessels such as bioreactors, fermentation tanks, or carboys. These filters maintain the sterility of the interior environment and protect the atmosphere from contaminants within the vessel.

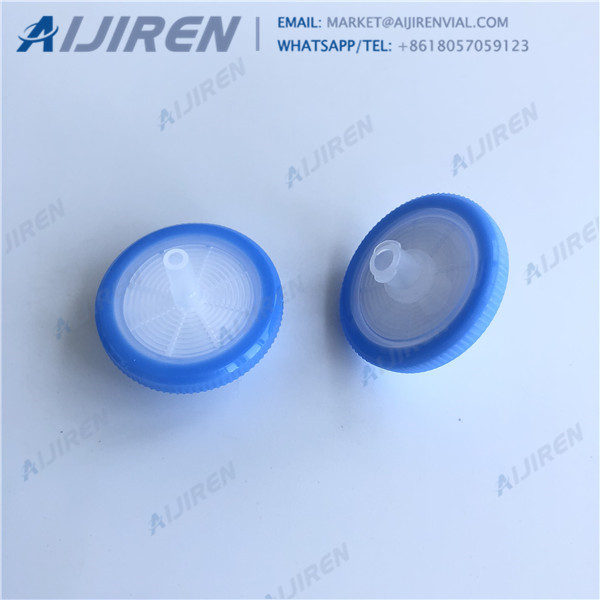

These Corning® syringe filters have polypropylene copolymer housings, hose barb inlets and hose barb outlets. PTFE membranes provide the best chemical resistance These naturally hydrophobic membranes can be used for venting applications or filtering gases 100% integrity tested, sterile and nonpyrogenic and noncytotoxic Manufactured in accordance with ISO 9001 standards

Materials Filter membrane: Hydrophilic Durapore ® polyvinylidene fluoride (PVDF), pore size 0.22 μm, type GV Vent membrane: Hydrophobic polytetrafluoroethylene (PTFE), pore size 0.03 μm Housing: Polyvinyl chloride (PVC) Dimensions Inlet to outlet: 27 mm (1.06 in.) Diameter: 29 mm (1.14 in.) Filtration area: 4 cm2 (0.62 in2) Temperature limit: 45 °C (113 °F) Pressure limit at 21 °C: 5.1

Pore sizes of 0.2 µm and 0.5 µm are typically used. Sterile* venting of vacuum manifolds, fermentation vessels, and filtrate tanks and containers utilize PTFE 0.2 µm membranes. Looking for a filter paper, membrane filter, or syringe filter? Let Cytiva help you find the optimal filter for your needs to ensure reliable analysis.