Cobetter ULPA filter uses pleated oleophobic PTFE membrane as the final filtration media to prevent any liquids (aquious or oils) from passing through the filter. Together with carbon or other pre-filtration layers, it provides 99.999% efficiency in removing airborne particles (0.12μm) in the operating room.

Fibrous filters like the glass fiber filter shown in Figure 1A consist of a deep mesh of fibers with random orientations. Porous membrane filters, such as those made from mixed cellulose esters (MCE) or polytetrafluoroethylene (PTFE), have a complex structure with tortuous routes through the filter material as shown in Figures 1B and 1C.

Reusable Filters are made from medical grade PTFE, is the robust and reusable medical media with dual capabilities: a vent that allows pressure equalization during the sterilization process and a filter bacteria barrier for subsequent storage conditions. Available in two configurations, in compliance with USP class VI requirements, Table 4

Dental - As bone barrier membranes, Aeos™ ePTFE provides a safe and non-toxic means to prevent gum from growing into grafted bone for procedures such as dental implants. Desiccant and Packaging Aids - Aeos™ ePTFE is breathable allowing air to pass while also filtering dust to protect sensitive electronics or other parts.The product is nonflammable, biocompatible, moisture blocking, and

Our Pleated Filter Bags come in either top-load or bottom-load configurations and can be constructed of the following medias good to 275 degrees F. max: Spun Bond, Aluminized Spun Bond (anti-static), Spun Bond with hydro oleo-phobic finish (water/oil resistant), Spun Bond with PTFE Membrane and Carbon Impregnated Spun Bond.

4. Can we sterilize Acro 50 PTFE vent filters by gamma irradiation? Acro® 50 Vents with PTFE media cannot be gamma irradiated as it has negative impact on membrane integrity. 5. Is there an inlet and outlet side to Acro® 50 Vents with PTFE? Yes, the printed side of the filter is the inlet side or upstream side. 6.

Saint-Gobain manufactures filters and membrane components of any size, fitting type, and configuration based on a global portfolio of filtration membranes and media combinations. Saint-Gobain's capsules and cartridges are manufactured in both industry standard and customer specified formats in Class 100,000 or 10,000 Clean Rooms.

Membrane filters designed to sterilize liquids and gases have performed successfully in a broad range of process applications. As economic and market conditions lead pharmaceutical, biotechnology and vaccine manufacturers to search for ways to improve profitability by decreasing process costs, re-using sterilizing-grade filters may be considered.

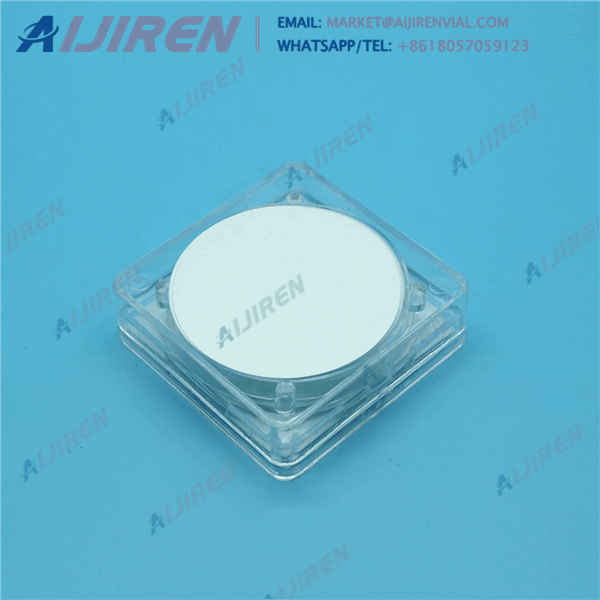

PTFE membranes are naturally hydrophobic, and chemically resistant to all solvents, acids and bases. PTFE membranes do not impart any extractables to the filtrate. PTFE is an ideal membrane for transducer protectors, since it blocks water vapor and is also ideal for filtering and de-gassing chromatography solvents.

ISO 1 is an international test standard for air filters that from 1 July 2018 has replaced EN 779. ISO 1 classifies air filters based on particulate matter (PM), which makes it possible to directly see connections to our health and air pollutants. Standard and regulations