Filter materials — PTFE filter+non-woven fabric (PE+PET) Pore size µm 1 1 Thickness µm 140 140 Flowrate L/min/cm 2 80 80 Bubble point Kg/cm 2 Unavailable Unavailable Heat resistance C 135 135 Width mm 40 — Length m (1 roll) 21 — Diam. mm — 47 2

Our ePTFE membrane is a very thin, porous layer that prevents particulate matter from entering the body of the filter bag. Without the ePTFE membrane, particulate matter will penetrate the conventional filter, making it weaker and more resistant to airflow

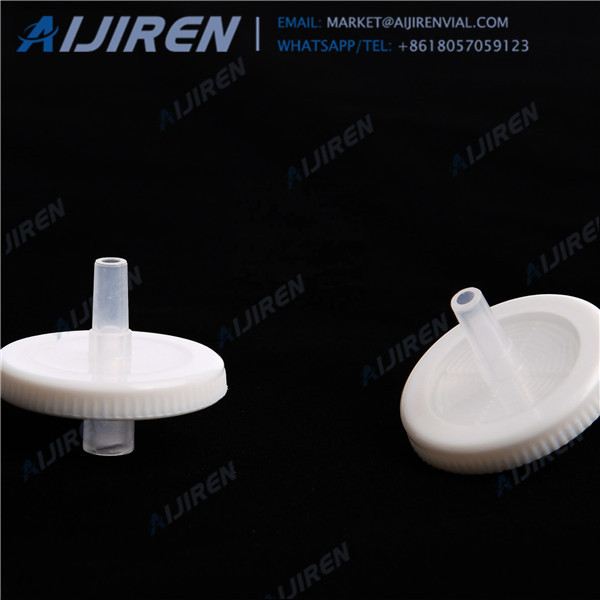

Today’s sterile air membrane cartridge filters are typically composed of PTFE media, due to this material’s high degree of natural hydrophobicity. They feature a fixed pore structure, with no chance for filter media flexing or unloading of contaminants, often a concern with depth filters.

Data Sheet: PTFE Felt Filter Bag 830 g/m 2 (24.5 oz/yd 2) Data Sheets, Inglés Compartir: Mail Copy URL Twitter Linked In Facebook A 260 C (500 F) maximum service temperature, polytetrafluoroethylene felt filter bag for use in pulse jet style dust collectors

Emflon PFR filters provide high assurance of filter integrity and long life, even during continuous use in hot air up to 60 C, in vent applications up to 80 C and during repeated steaming. These PTFE filter cartridges can withstand up to 1 bar (14.5 psi) differential

Published: Dec. 2008 Demand for membranes in South Africa is set to increase, with the market tripling by 2014, according to a new report by Frost and Sullivan. According to the South African Membrane Market, the market earned revenues of US$37.5M in 2007 and estimates this to more than triple by 2014 to reach US$143.9M.

CS30 PTFE fibre impregnation is used to filter fine, well-adhering dusts. Its PTFE properties make it both extremely durable and chemically resistant. CS31 is a combination of CS30 with a CS17 ® finish. It is also water- and oil-repellent. It also protects the

GE South Africa is involved in the construction and management of the Medupi and Kusile Power stations and donated and fully kitted the Nelson Mandela Children’s Hospital with healthcare equipment. We are a responsible corporate citizen with a strong commitment to contributing to South Africa’s sustainable development especially in skills and small medium enterprise development.

Absolute Rated PTFE Membrane Filter Cartridge TefTEC cartridge filters are constructed with naturally hydrophobic PTFE membrane and polypropylene support layers and components. The HIMA retentive PTFE membrane offers superior hydrophobicity and water intrusion resistance compared to PVDF and polypropylene membranes, and the cartridge construction offers a cost-effective alternative to all fluorocarbon filters.

Power Generation Mining & Minerals Valve Repairs Downloads Contact Us SOUTH AFRICA 0861 103 103 Email Home About Us About Us News Careers Brands Actreg Arca HP Valves JC Valves NAF Pibiviesse PMV Procontrol Richter Schroeder Stafsj

Filter Media wwPTFE (water wettable PTFE), TF (PTFE, hydrophobic polytetrafluoroethylene), PVDF (hydrophilic polyvinylidene fluoride), and Nylaflo (hydrophilic nylon) membranes Pore Size 0.2 and 0.45 μm Typical Thickness wwPTFE Membrane 0.2 μm: 280

Global Membrane Filter Cartridge Market Overview The Global Membrane Filter Cartridge Market is growing at a faster pace with substantial growth rates over the last few years and is estimated that the market will grow significantly in the forecasted period i.e. 2019

Clear Edge contributes to lessening the effect of power generation on the Earth’s and people’s health with high-quality filter media. View This Solution Clear Edge is filtration specialists with pioneer filter media that sustain automotive application processes whilst achieving maximum performance.

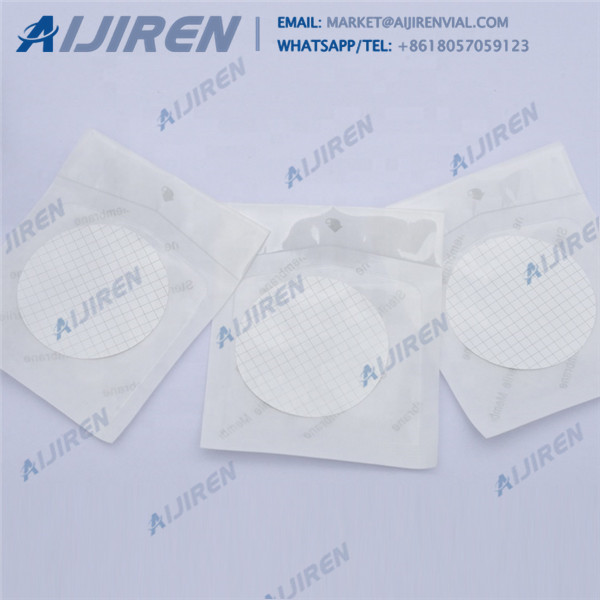

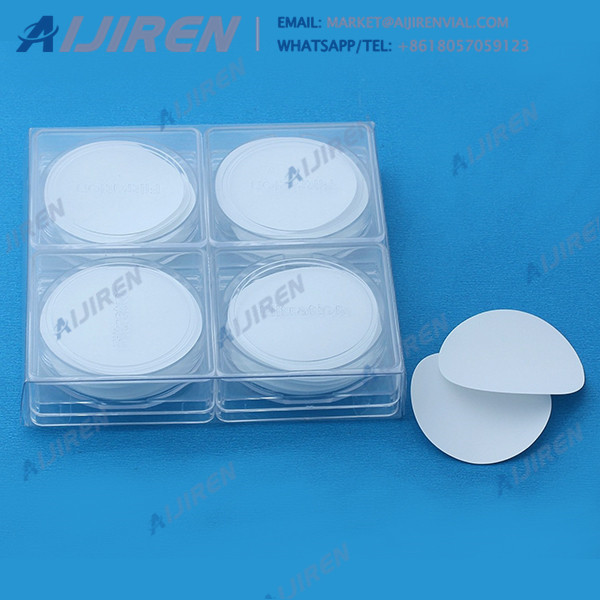

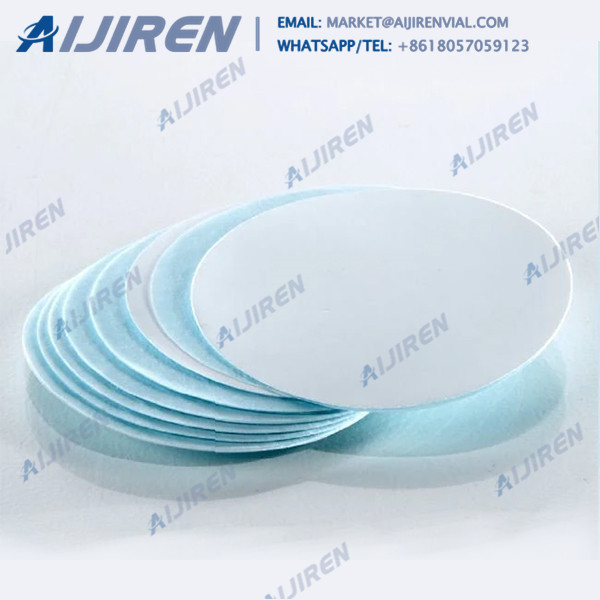

PTFE Membrane Disc Filters Strong, Chemically Resistant Membranes for Air Monitoring and Sampling in Aggressive Environments Low chemical background permits

Modified free-flowing suspension PTFE of the 2nd generation for compression moulding and ram extrusion applications like shaped parts, skived films, seals and valve seats. Special Features Meets ASTM D4894 Type III, Grade 2 classification, Produced by suspension polymerisation, Good mould filling behaviour, Very good free-flowing properties, Improved particle coalescence.