Also called Acid Caps, these polypropylene caps are acid resistant. This F422 liner is comprised of a .38” LDPE core sandwiched between identical layers of .002” - .003” virgin HDPE. Unlined polypropylene closures are available in white or black. These caps are autoclavable and

2019/2/19 · Let us understand the PTFE PVDF difference in the following three aspects. PTFE vs PVDF 1. Solvent resistance, acid, and alkali resistance are different for PVDF vs PTFE. PTFE membrane, its use temperature is -40~260 , can withstand strong acid, strong

Fluoropore™ Membrane is a hydrophobic, polytetrafluoroethylene (PTFE) polymer membrane bonded to a high density polyethylene support. (Catalogue numbers containing ""FHUP"" have no backing.) Fluoropore™ Membranes provide broad chemical compatibility, high flow rates and consistency. Omnipore™ Membrane is hydrophilic PTFE compatible with

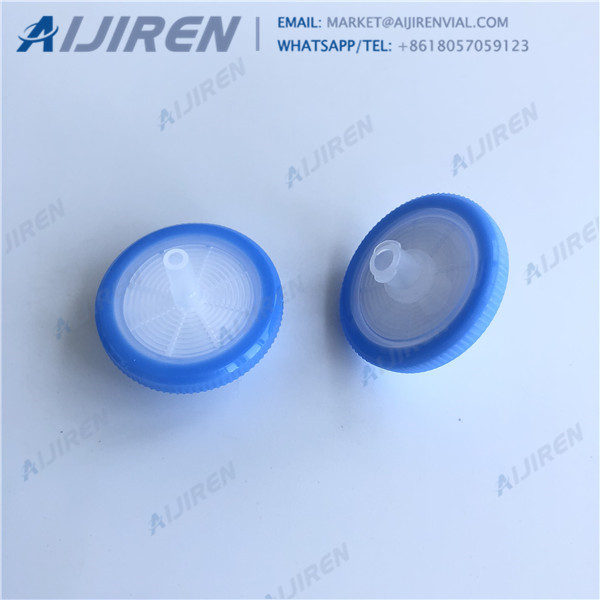

Chemical compatibility is a critical consideration when selecting the proper sample prep syringe filter for your application. This chart outlines the chemical compatibility of the most common syringe filters. The contact time was 24 hours at 20 C. Syringe Filter

Product Number Product Description SDS SLLGX13 Replaces SLLGH13NL, 0.20 µm pore size, 13 mm diameter, Millex-LG hydrophilic PTFE membrane Pricing SLCRX13 Replaces SLCR013NL & Z227420, 0.45 µm pore size, 13 mm diameter, Millex-LCR

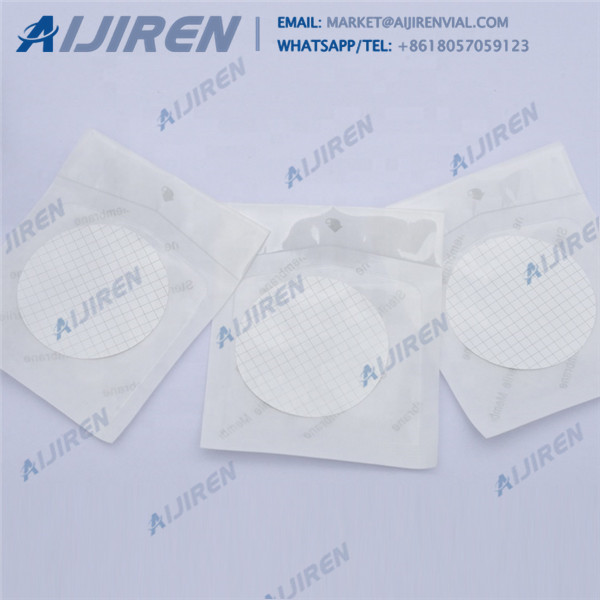

Aluminum oxide (AO) membranes feature uniform, densely-packed honeycomb pore structures that contribute to precise retention and high porosity characteristics. Composed of pure anodized aluminum, these filters have essentially no organic extractables. Read

Pricing. SLFGL25BS. A 25 mm diameter sterile syringe filter with a 0.2 µm pore size hydrophobic PTFE membrane, with Luer outlet, ethylene oxide sterilized. Comes in a pack of 50. Pricing. Match Criteria: Product Name. Millex Syringe Filter, Fluoropore® PTFE, Hydrophobic, Non-sterile.

Fluorinated ethylene propylene (FEP) is a copolymer of hexafluoropropylene and tetrafluoroethylene. It differs from the polytetrafluoroethylene (PTFE) resins in that it is melt-processable using conventional injection molding and screw extrusion techniques.[2] Fluorinated ethylene propylene was invented by DuPont and is sold under the

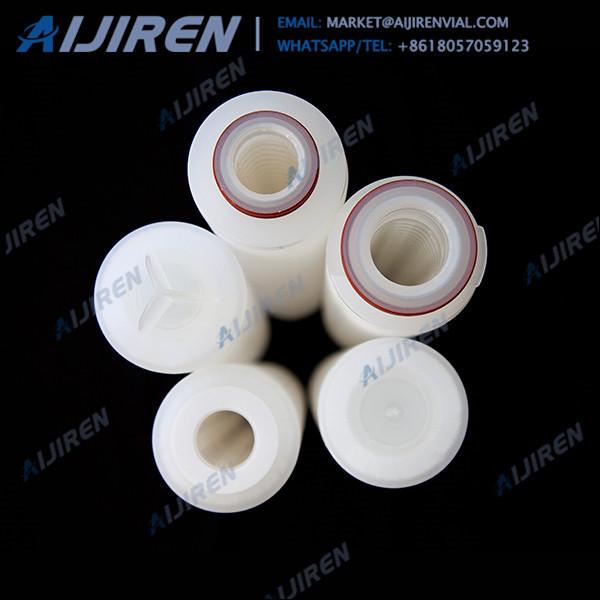

Can withstand aggressive solvents, liquids and gases that may damage other membranes Polypropylene support material for improved strength and handling One of the major applications for the PTFE membrane is the clarification of corrosives, solvents and aggressive fluids.

The PTFE backbone interlaced with the ionic sulfonate groups gives Nafion a high operating temperature, e.g. up to 190 C, however, in membrane form, this is not

Teflon™ AF is available as a powdered resin or solution in two grades: AF 1600 (*Tg 160 °C [320 °F]) and AF 2400 (Tg 240 °C [464 °F]). Resins. AF 1600. AF 2400. Solutions. AF 2400 1%. AF 1601 6%. AF 1601 18%. For more information, see the Teflon™ AF Resins Performance and Processing pages.

The Membrane and Process Development Product line at Sterlitech includes a wide range of commercially available polymeric flat sheet membranes, as well as ceramic membranes, bench-scale cross/tangential flow test cells, and filtration equipment. Sterlitech also offers Custom Designed Skid Mount Membrane Filtration Systems.

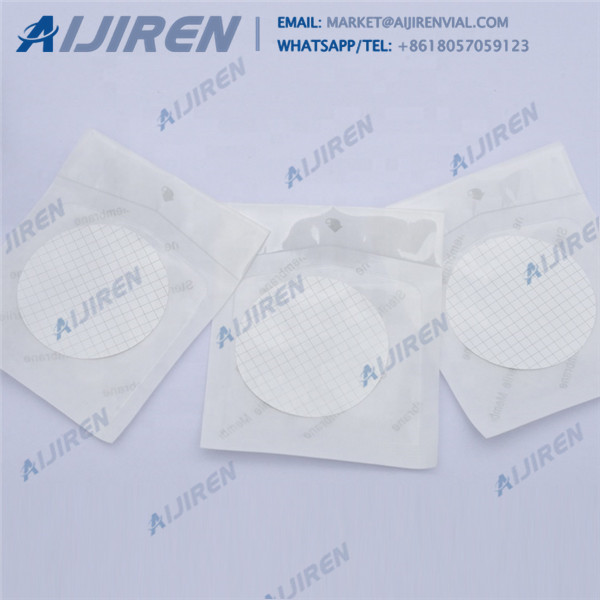

![<h3>Welded Syringe Filters, Pack of 100, [PTFE Hydrophilic Membrane] </h3>](/wp-content/themes/aijiren/load/10/Wholesales ptfe membrane.png)

Polytetrafluoroethylene (PTFE) PTFE membranes are chemically resistant to nearly all solvents, acids and bases. The membrane has low extractable and good thermal stability. Membrane: HPLC certified PTFE, with polypropylene support Use with:

PTFE membrane filters have an excellent chemical compatibility (pH 1 to 14), so that they are also used for the filtration of solvents and acids, to which other filter types are not resistant. Moreover they can be used to filter aqueous solutions as well, but because of their hydrophobic characteristics, they must be pre-wetted with ethanol or methanol before the filtration of aqueous media

2021/3/18 · FESEM was employed to investigate the morphology of the porous PTFE substrate ().There were no huge changes in porous structure of the PTFE membranes before 24 h co-deposition reaction (Fig. 2(b)).As the co-deposition time increases from 24 h to 48 h (Fig. 2(c)), the thickness of PTFE fiber increases by about 5–7 nm.