980 Properties of PTFE tape as a semipermeable membrane in fluorous reactions Brendon€A.€Parsons1,2, Olivia€Lin€Smith1, Myeong€Chae1 and€Veljko€Dragojlovic*1 Full Research Paper Open Access Address: 1Wilkes Honors College of Florida Atlantic University, 5353 Parkside

Chemical Compatibility. PES membranes were exposed to the following chemicals for 48 hours. If there was no significant change in the bubble point, strength or appearance of the membrane, it was judged compatible with the chemical. If the membrane dissolved, or otherwise lost its strength, or changed significantly in appearance, it was rated

2019/9/11 · These four folding filter cartridges have excellent chemical compatibility, suitable for filtering strong acid, strong alkali and organic solvent, large membrane filtration area, low pressure difference, strong dirt holding capacity and more effective application life.

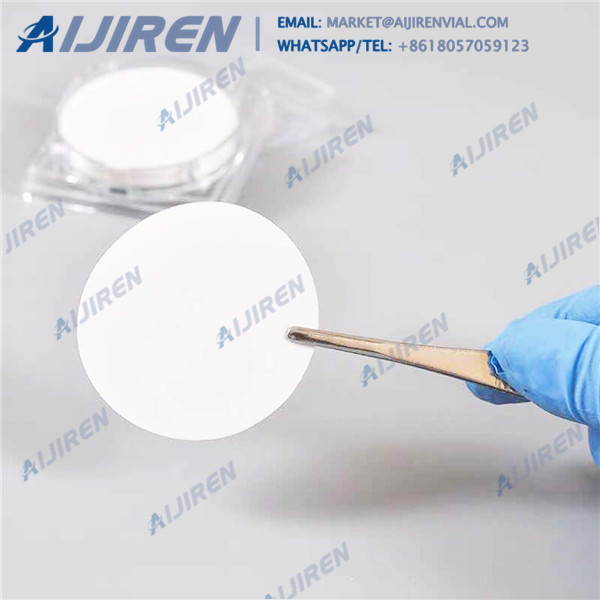

2020/2/5 · PTFE flat porous disc-shaped membranes laminated with polypropylene (PP) (the PTFE side is used as the feed side, while the PP or support side is used as the permeate side), with pore diameter (d pores ) of 220 nm and membrane diameter (d membrane ) of 47mm, were purchased from Filtres-Fioroni,

Thomson SINGLE StEP® Filter Vials Solvent Compatibility Chart R = ecommended. No significant change observed in flow rate or bubble R point of the membrane, nor visible indication of chemical attack. L = ed Recommended Use. Moderate changes in

Solvent/Water Separation by Pervaporation and Vapor Permeation The emerging membrane technologies of PV and VP have been investigated for separating a variety of mixtures of volatile liquids, most often involving solvent/water mixtures.

2005/10/4 · The performance of direct methanol fuel cells (DMFCs) with a Nafion/PTFE composite membrane, which was prepared in-house, a commercial Nafion-117 membrane, or a commercial Nafion-112 membrane were investigated by feeding various concentrations, i.e., 2–5 M, of methanol to the anode. The Nafion/PTFE composite membrane gave a better DMFC

POREX® TMF-B13/37 All PVDF Tubular Membrane Filter (TMF) Bundles FILTRATION Optimal high solids separation at high flux rates POREX TMF cross-flow tubular membrane bundles contain Porex’s patented* structural membrane tubes. The superior strength

Membrane material polytetrafluoroethylene (PTFE) Diameter: 13, 25, 47, 90, 142 y 293 mm. Pores: 0.22, 0.45, 1.2 y 5.0 µm Maximum temperature of use ≤ 180ºC Extractables with water: No Sterilization: Using a gamma irradiation, ethylene oxide, autoclave

verify chemical compatibility with a specific filter under actual use conditions. Because chemical compatibility is affected by many variables (including temperature, pressure, concentration, and purity), various chemical combinations prevent

Syringe Filters Solvent Compatibility Chart 1 Protect any analytical system. 2 Extend LC column lifetime. 3 Achieve more reproducible analyses. 4 Variety of membranes, porosities, and diameters available. 5 Luer lock inlet provides strong, leak-tight syringe connection to withstand

and properties of microporous membrane from PVDF-co-PTFE for membrane distillation reported that the addition of TFE in PVDF gave a superior mechanical strength compared to PVDF [21]. In this work, three different solvents (N,N-dimethylacetamide, N-methyl-2-pyrrolidone and N,N-dimethyl-

PTFE Laminated Membrane Filters. These hydrophobic PTFE membrane filters are laminated onto polypropylene netting for improved strength and handling. Due to broad chemical compatibility and excellent water repellency, they are ideal for solvent filtration, phase separations, venting, and air sampling. Read More.

Savana® PTFE Filters. Constructed with PTFE membrane and PP supports for enhanced durability and cleanliness. Hydrophobic Membranes. Hydrophobic version for air filtration, stripper and IPA or solvent applications in flat panel display or hard disk industries. Hydrophobic membranes do not require prewetting in solvent-based chemicals.

2018/8/7 · Cellulose Nitrate (CN) Membrane. Hydrophilic membrane with limited resistance to organic solvents, but is strong and flexible, with a high flow rate. Cellulose nitrate is compatible with some solvents that cellulose acetate is not. DO USE: for acetic acid, carbon tetrachloride, chloroform, cresol, and