Chemical Compatibility Reference Chart Teflon® PTFE Teflon®* PTFE Chemical Compatibility Chart: Check the chemical compatibility of Teflon® and PTFE with various chemicals, solvents, alcohols and other products. Polytetrafluoroethylene (PTFE) is very non-reactive and is often used in containers holding reactive and corrosive chemicals.

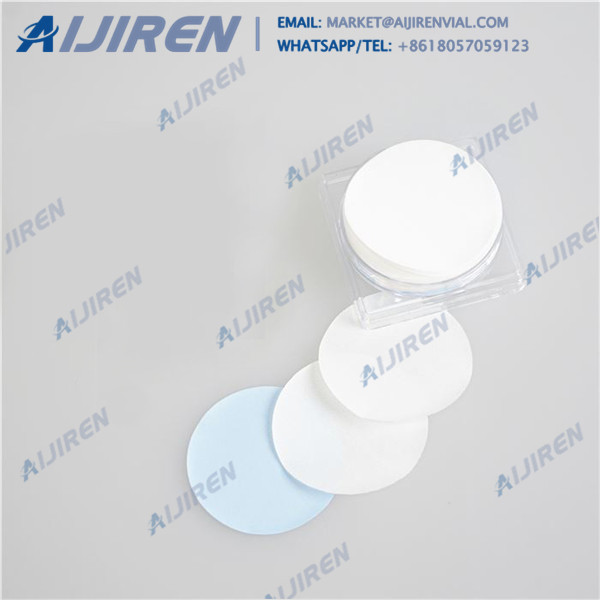

Choose a filter or membrane based on: 1) Chemical compatibility of the membrane and housing with your sample matrix. 2) Size and amount of particulates in the sample. 3) Potential interactions (binding) between the membrane and sample components. 4) Special considerations such as requirement for prefilter or inorganic ion certification.

the high-temperature attributes of PTFE, long continuous lengths, and almost as much clarity as FEP. Very good purity. PFA Parflex PTFE, FEP and PFA tubing complies with European Standard RoHs and the tubing is also FDA compliant to FDA regulation 21 CFR 177.1550, making these products suitable for use in food and beverage applications.

.jpg)

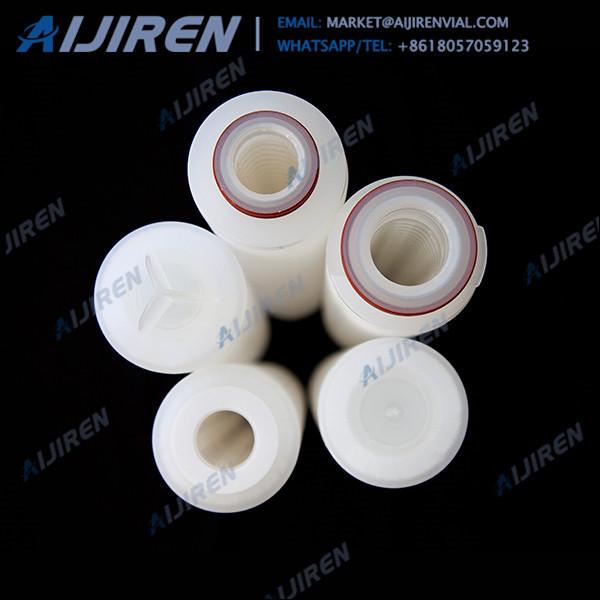

• Each food&beverage grade filter cartridge has been washed by pure water. LFT Hydrophobic PTFE Filter Cartridge • The hydrophobic PTFE membrane is from Donaldson company,Inc. •T he membrane stack consists of PTFE filter membrane and imported deflector layer

PTFE membrane filters are used in a variety of applications in industries such as pharmaceutical, biosciences, laboratory testing, food and beverages, chemical engineering and air filtration. PTFE membranes have an extensive compatibility to numerous chemicals and can be exposed to higher temperatures.

Membralox ceramic elements featuring an asymmetric membrane structure combine a unique design and manufacturing process resulting in a product ideally suited for applications involving chemicals, including solvents, extremes of pH, high temperatures and pressure processing of and fermentation broths. The compact multi-channel geometry and high

MS ® PTFE Filtration for Chemical. DESCRIPTION. MS ® PTFE membrane can be widely used in various fields ranging from pharmaceutical industry and microelectronics to chemical processing because of its perfect properties of broad chemical compatibility,high flow rate and long service life.Here,we introduce the application in chemical processing&other besides the applications in pharmaceutical

• PTFE membrane and polypropylene component construction offers excellent chemical compatibility and cost effectiveness versus all fluoropolymer filters • Complies with Food & Drug Administration’s CFR criteria for food & beverage contact • Meets USP Class VI Biological Test for plastics.

PTFE is chemically stable and inert. It has excellent compatibility with aggressive solvents and acids. It exhibits low protein binding and is recommended for the filtration of non-aqueous samples e.g. HPLC solvent preparation and degassing to ensure column protection.

• Inert PTFE and polypropylene components provide extremely wide chemical compatibility, and permit use in a broad range of fluids and applications • Absolute ratings of 0.05, 0.1, 0.2, 0.4, 1.0 and 5.0 micron deliver precise particle retention at rated level • Highly porous PTFE membrane assures high flow rates, long service life and

PTFE Chemical Compatibility Chart A Suitable B Consult with TEADIT C Not recommended PRODUCT TF1570 TF1580 TF1590 Teadit 24SH Teadit 24B TF 1510 Chlorine Trifluoride C C C C C Chlorine, Dry or Wet A A A A A Chloroacetic Acid A A A A A 2-Chloroacetophenone A A A A A Chloroazotic Acid (Aqua Regia) A A A A A

3M™ Capillary Membrane MF-PP Series. Capillary and tubular membrane MF-PP Series. Inner diameters range from 50 µm to 5500 µm. These capillary membranes are widely used in the food and beverage industry, in waste water filtration and sterile filtration. MF-PP Series capillary membranes are also ideal for use in heavy-duty filtration

BTH series PTFE pleated filter element adopts polytetrafluoroethylene (PTFE) filter membrane, which has excellent chemical resistance, corrosion resistance and natural hydrophobicity. It strictly controls the precipitation of metal ions and is suitable for most chemicals, organic solvents and compressed air.

Food And Beverage Pumps. FDA-compliant food and beverage with Polypropylene, PVDF with Santoprene® or PTFE elastomers. Tri-Clamp®. Liquid end made from passivated stainless steel, high-polished stainless steel or polished stainless steel. Maximum pump temperature of 225°F (107°C) Pump. F100.

CLEAL®POROUSFINEF-Series is a pleated cartridge composed of a membrane filter made of PTFE and polypropylene with broad chemical compatibility, and is a clean filter which does not contain any adhesives.