Choose a filter or membrane based on: 1) Chemical compatibility of the membrane and housing with your sample matrix. 2) Size and amount of particulates in the sample. 3) Potential interactions (binding) between the membrane and sample components. 4) Special considerations such as requirement for prefilter or inorganic ion certification.

relate to a membrane that may respond almost immediately to immersion in solvent. In addition, solvent-membrane compatibility requires additional consideration of filtration-specific factors. None of these published compatibility guides, for example, monitors the solvent's ability to wet a membrane or increase extractables. 4.

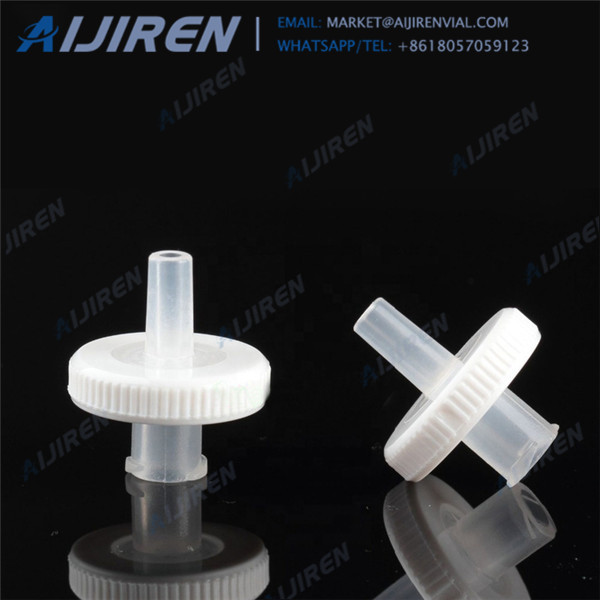

Syringe Filters Solvent Compatibility Chart 1 Protect any analytical system. 2 Extend LC column lifetime. 3 Achieve more reproducible analyses. 4 Variety of membranes, porosities, and diameters available. 5 Luer lock inlet provides strong, leak-tight syringe connection to withstand filtration pressure. 6 Rugged polypropylene construction— autoclavable to 121 °C for

Chemical compatibilities can be influenced by various factors. Therefore, we recommend that yo u confirm compatibility with the liquid you want to filter by performing a trial filtration run before you start your actual filtration.

PTFE Chemical Compatibility Chart: Polytetrafluoroethylene is very non-reactive and ideal for use with most chemicals.. Review the chemical compatibility of Teflon® and PTFE with various chemicals, solvents, alcohols and other products in the cart below.

Filterware/Chemical Resistance for Membranes and Housings Membranes Housings Chemicals C.N.* C.A./SFCA GFP NYL aPES/PES PTFE PVDF HDPE PS PSF ACR PP Acids Acetic acid, 25 % S M M M S S S S M M M S Acetic acid, 100% (glacial) U U M M M S S S U U U S Formic acid, 25% S M S U S S S S U M M S Formic acid, 100% M U S U M S S S U U U S

The definition of solvent compatibility for Millipore products differs from that used in determining the ratings given in published compatibility tables. Such tables are generally concerned with chemical attack and significant losses in strength and/or dimensional changes. A top designation, for example, might be designated for solvent-polymer

In addition, solvent-membrane compatibility requires additional consideration of filtration specific factors. None of these published compatibility guides, for example, monitors the sol-vent's ability to wet a membrane or increase extractables. 4. This table does not consider solvent safety issues. References used in developing this table

Membrane integrity for syringe filters was tested by bubble point. This chart is intended only as a guide. Accuracy cannot be guaranteed. Users should verify chemical compatibility with a specific filter under actual use conditions. Because chemical compatibility is affected by many variables (including temperature,

1 FILTRATION Selecting the Best Filter for Your Application Choosing a filter does not have to be complicated - Corning has simplified the process. Just follow these four easy steps: Step 1: Match your application with the appropriate pore size. Step 2: Select the membrane and housing material for your application. Step 3: Select the correct membrane area to optimize flow rate and throughput.