Chemical Compatibility Chart PTFE PVC PVDF (Kynar®) Silicone (VMQ) Titanium Viton® (FKM) Acetaldehyde A A D A C B A A D C C D A A B A C C C C N/A A C A A D D A ...

PTFE Chemical Compatibility Chart: Polytetrafluoroethylene is very non-reactive and ideal for use with most chemicals.. Review the chemical compatibility of Teflon® and PTFE with various chemicals, solvents, alcohols and other products in the cart below.

Nov 15, 2017 · Materials for GTR membrane can be roughly categorized into two groups according to their degradation property, namely non-resorbable and resorbable materials. Both types of GTR materials exert similar clinical results [28, 29]. The non-biodegradable material currently available is polytetrafluoroethylene (PTFE) and methylcellulose acetate .

Incorporating flexible titanium in PTFE membranes allows the surgeon to shape the membrane to adapt it to the implant area. When compared to PTFE alone, titanium-reinforced PTFE could provide superior stability of the material for some types of bone defects, such as in supracrestal bone defects and in sites with buccal dehiscence.

Aug 07, 2018 · Hopefully, this quick overview helps you identify the most appropriate membrane-solvent combination for your application. To compare between all the common membranes and solvents, review the chemical compatibility chart in our guide to laboratory membrane filtration principles and chemical compatibility.

In rare cases, a solvent might partly or fully dissolve the membrane, resulting in breakthrough and potential contamination of the sample. Aqueous samples are unlikely to damage most membrane materials, particularly hydrophilic. However, pH is a significant factor in determining membrane compatibility.

relate to a membrane that may respond almost immediately to immersion in solvent. In addition, solvent-membrane compatibility requires additional consideration of filtration-specific factors. None of these published compatibility guides, for example, monitors the solvent’s ability to wet a membrane or increase extractables. 4.

PTFE Chemical Compatibility Chart A Suitable B Consult with TEADIT C Not recommended PRODUCT TF1570 TF1580 TF1590 Teadit 24SH Teadit 24B TF 1510 Chlorine Trifluoride C C C C C Chlorine, Dry or Wet A A A A A Chloroacetic Acid A A A A A 2-Chloroacetophenone A A A A A Chloroazotic Acid (Aqua Regia) A A A A A

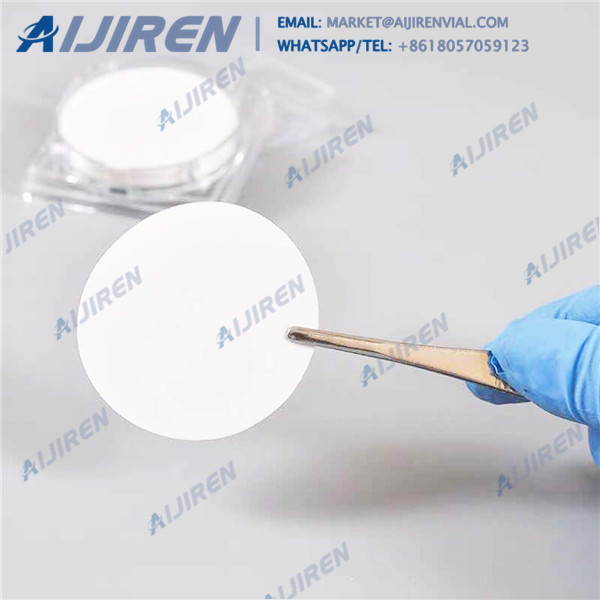

3M produces a broad range of microporous flat sheet and capillary membranes for use in various industries. Our capillary and flat sheet hydrophobic and hydrophilic membranes are made from a variety of materials, such as polyethersulfone and polypropylene, to meet highly diversified market requirements. 3M supplies these membranes to filtration module manufacturers or cartridge producers to

Jan 07, 2021 · It was demonstrated that the PTFE membrane displayed an attractive permeation flux with a value of 5700 g·m −2 ·h −1, whilst the extracted ethanol concentration was 6–8 times higher than that in feed . Aroujalian et al. also applied the microporous PTFE membrane with the same pore diameter to separate ethanol/water mixtures.

Despite the excellent chemical and thermal stability of hydrophobic polymers (e.g., polytetrafluoroethylene (PTFE) and polyvinylfluoridine (PVDF) membranes are used in UF and MF of organic solutions), stable hydrophilic polymers are more effective as membrane materials because of their reduced adsorption tendencies.

Nafion is a brand name for a sulfonated tetrafluoroethylene based fluoropolymer - copolymer discovered in the late 1960s by Walther Grot of DuPont. Nafion is a brand of the Chemours company. It is the first of a class of synthetic polymers with ionic properties that are called ionomers.

Chemical Compatibility Guide FFKM (Perfluoro Rubber) Perfluoroelastomers show broad chemical resistance similar to PTFE as well as good heat resistance. They show low swelling with almost all media. Depending on the material the operating temperatures range between -25 °C/-13 °F and +240 °C/+464 °F Special types can be used

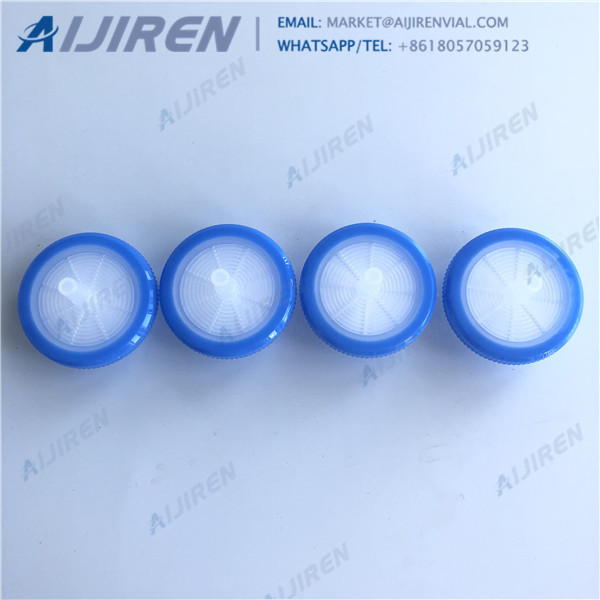

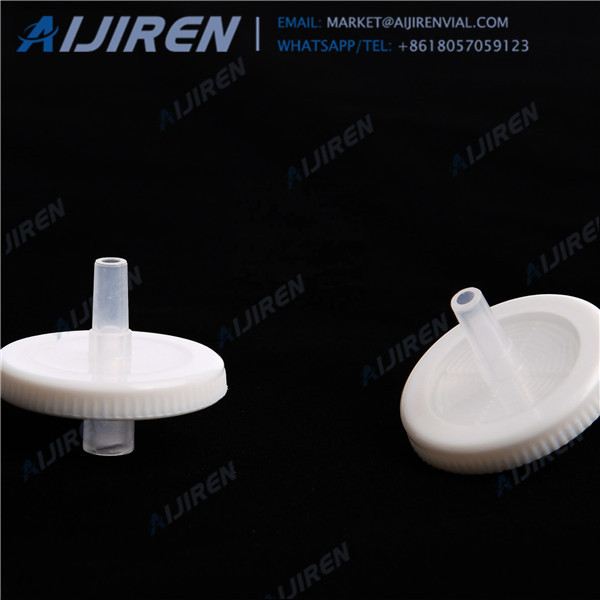

Jan 04, 2017 · Choose The Right Syringe Filter For Your Liquid Or Gas. Syringe filters are normally used in scientific research laboratories to remove certain sized particles or bacteria from certain volume of liquid or gas prior to analysis or cell culture. Syringe filters are popularly used in HPLC analysis. In cell culture hood syringe filters are normally