who are we. It is a. China ePTFE air purification composite materials manufacturers. , our factory specializing in the development and production of expanded polytetrafluoroethylene (PTFE) microporous membrane and related composite products.

Millex-FG, 0.20 µm, hydrophobic PTFE, 50 mm. Background Information. Millex® syringe filter units with hydrophobic Fluoropore™ or Millipore Express® PLUS PES membrane are ideal for in-line sterilization of gases and venting sterile containers, and filters with Fluoropore™ membrane can also be used for sterilizing or clarifying organic

Use of PTFE membrane for in-situ gas phase extraction from natural Aijiren Technology. de Gregorio, S. ; Gurrieri, S. ; Valenza, M. Abstract. The extraction of the dissolved gas phase in natural Aijiren Technology is a delicate operation which can frequently invalidate the analytical data. Several methodologies were developed in order to separate the dissolved gaseous

PTFE microporous membrane pleated filter element is made of natural hydrophobic polytetrafluoroethylene (PTFE) membrane and polypropylene material parts by advanced hot-melt sealing technology in a controlled Class-100 clean environment without any adhesive and surfactant, and meets the technical requirements of the national standard of the

Other Membrane Filters Polyethersulfone (PES) Membrane Filters Polyvinylidene Fluoride (PVDF) Membrane Filters PTFE Membrane Filters Reagents for Amino Acid Analysis Systems Reference books Sample Extraction System Accessories Septa Standards

Sanitization, Sterilization, Cleaning & Storage Guide for PES, PVDF, and PTFE Membrane, and Polypropylene & Fiberglass Depth Media Cartridge Filters Page 3 Below are the procedures for in-situ sanitizing/sterilizing of filters using heat. Contact Critical Process

Description of Polypropylene Membrane Filter Microporous membrane filter 0.45 μm is made of polypropylene ultrafine fibers by hot melt bonding, which is a kind of membrane material for deep filtration. As a polypropylene membrane filter suppliers, the pp membrane is made of food-grade isotactic polypropylene, without any additives in the whole production process.

These PTFE filter cartridges can withstand up to 1 bar (14.5 psi) differential pressure (forward direction) under steam sterilization conditions (125 C). This is combined with high flow rates and excellent dewetting characteristics resulting in very economical filtration through the use of smaller installations and reduced energy costs.

ePTFE sterilization high-efficiency composite material adopts PP and PET non-woven fabrics of well-known brands at home and abroad as carriers. And use of international leading composite technology to make the membrane and substrate perfectly combined, focus on the gas, liquid and other sterilization and high-precision filtration.

PTFE membranes are particularly suitable for preparing samples for HPLC analysis. The hydrophobic nature of the membrane also has applications for air and gas sterilization. The membrane is laminated onto a nonwoven polypropylene support web for improved strength and handling and can be used at temperatures up to 120ºC.

Applications of PES pleated membrane filter cartridge The removal of particulates from electronic high-purity water and electronic chemicals. It is used in the bio-pharmaceutical industry for the removal of particles and sterilization of liquids and process Aijiren Technology.

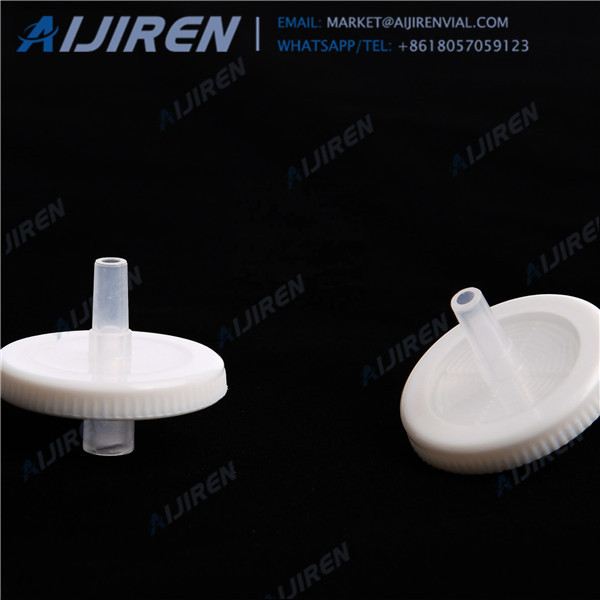

PTFE disposable syringe filter is a fast, convenient and reliable filter tool, often used in laboratories. It has the characteristics of beautiful appearance, light weight and high cleanliness. Because there is no need to replace the filter membrane and clean the filter

Grafting of Styrene onto Commercial PTFE Membrane and Sulfonation for Possible Use in Fuel Cell E.E. Abdel-Hady 1 , M.M. El-Toony 2 *, M.O. Abdel-Hamed and A.M. Hammam 3

Membrane Type (PTFE, GHP, PVDF, Nylon) — Typically, the first step in selecting a suitable filter is to choose a membrane that is chemically compatible with the sample (see chart opposite). For aqueous samples, it is preferable to use a hydrophilic membrane (GHP, PVDF or Nylon) versus a hydrophobic membrane (PTFE).