Purpose: The primary aim of this randomized, controlled, blinded clinical trial was to compare the effect of a resorbable collagen membrane (CM group) versus a nonresorbable high-density polytetrafluoroethylene membrane (PTFE group) on the clinical and histologic outcomes of a ridge preservation procedure.

PTFE membrane is used extensively in many different industries: Petrochemical and chemical processing: PTFE is the material of choice for gaskets, vessel linings, pump interiors, washers, rings, seals, spacers, dip tubes and well-drilling components because it is corrosion resistant and chemically inert; it is unaffected by virtually all acids and caustics and functions in environments to 500 degrees F..

Teflo Membrane: TF (PTFE) Membrane: Filter Media/Support: PTFE with PMP (polymethyl-pentene) support ring: PTFE on a polypropylene support: Typical Thickness: 1 μm: 76 μm (3 mils) 2 μm: 46 μm (1.8 mils) 3 μm: 30.4 μm (1.2 mils) 0.2 μm: 139 μm (5.5 mils) 0.45 and 1 μm: 135 μm (5.3 mils) Typical Air Flow Rate L/min/cm2 at 0.7 bar (70

fluoropolymers, PTFE and PFA, in industry globally and clarify the differences between them. Defining PTFE and PFA Polytetrafluoroethylene (PTFE) is a syntheti c fluoropolymer of tetrafluoroethylene that has numerous applications. The most widely known PTFE formulation is sold under the brand name of Teflon®. PTFE was discovered by DuPont Co

Commercial membrane prepared by stretching is Gore–Tex. The polymer here is PTFE, which is what makes the membrane extremely inert and thus convenient for processing even harsh streams. Processing PTFE is possible only by paste extrusion. In paste forming, the polymer is mixed with a lubricant such as odorless mineral spirits naphtha or kerosene.

Expanded Polytetrafluoroethylene (PTFE) + Perfluoroalkoxy (PFA) End Configuration. Double Open End, Single Open End. Typical Flow per 10" (5mm) up to 70 lpm @ 100 mbard. Operating Conditions. 190°C @ 1.2 bar (d) Materials Conformity. FDA; EC, EU, USP, Halal.

Polytetrafluoroethylene (PTFE) is suitable for industries such as chemical, petrochemical, oil refining, chlor-alkali, acid production, phosphate fertilizer, pharmaceuticals, pesticides, chemical fiber, dyeing, coking, coal gas, organic synthesis, non-ferrous smelting, steel, atomic energy and polymer filter materials, Production of high-purity

An ePTFE membrane is created when PTFE — a linear polymer consisting of fluorine and carbon molecules — is expanded, creating a microporous structure with very desirable characteristics, including a high strength-to-weight ratio, biocompatibility, high thermal resistance and many others:

Global PTFE Membrane Market Size, Share, Trends and Industry Analysis now available from IndustryARC. Report reveals PTFE Membrane Market in the industry by Type, Products and Application.

PTFE flexible membranes (diaphragms) PTFE diaphragms, also referred to as membranes, are air-tight seals between two spaces with product and pressure, which typically differ from each other. Commonly used in pumps for the chemical and petrochemical industry, food and beverage industry and the pharmaceutical industry. This type of diaphragm or membrane is manufactured according customer specification.

The modern petrochemical industry has higher and higher requirements for sealing materials, requiring sealing gaskets to be resistant to corrosion by a variety of media, have a wide application temperature range, have sufficient mechanical strength at high temperatures and maintain dimensional stability. In terms of both corrosion resistance and temperature resistance, PTFE is undoubtedly the most ideal material.

Buy Advantec's Hydrophilic PTFE Membranes in a range of pore-sizes/diameters; reduce process times and optimize sample analysis in HPLC separations; strong polytetrafluoroethylene, highly chemically compatible/pH resistant, and ideal for aqueous/organic solvents and HPLC separations.

Whatman PTFE membrane filters from Cytiva's business are chemically stable and inert, making them suitable for use with aggressive organic solvents, strong acids, and alkalis. The TE range features polypropylene support material for improved strength and handling. Temperature resistant up to 120°C.

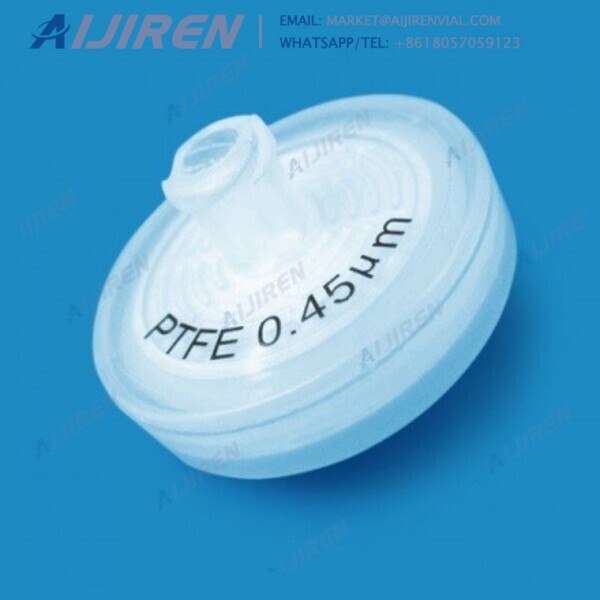

This is a 18 mm Hydrophobic PTFE Membrane Filter with a 0.45 micron pore size. For use in Sterilizing filtration, bioassays, solvent filtration. This Biopore membrane roll is hydrophilic, with a pore size of 0.4 microns. Non sterile Universal bottletop vacuum filter with Hydrophobic PTFE Fluoropore membrane.

KALIS-TF. KALIS Series – Polytetrafluoroethylene (PTFE) Hydrophobic Membrane with PP Hardware. Product Information. Description. Hydrophobic Membrane with PP Hardware. Applications. Air, Gas & Vent Filtration; Sterile Barrier, Bio-Burden Control, Fermentation, Sparging. Micron Rating (mm)