(PTFE), polypropylene, and cellulose acetate among others [14]. Inorganic membranes are made from such materials as ceramics, metals, zeolites, or silica. They are chemically and thermally stable and used widely in industrial [13,15].

Hydrophobic PTFE membrane • Increases surface area • Improves flow • Minimizes pressure drop All-PTFE fluoropolymer materials and thermally bonded construction • Ensure excellent chemical compatibility • Minimize chloride and metals extractables that

These ptfe membrane manufacturers are applicable in hotels, building material shops, manufacturing plants, machinery repair shops, farms, restaurants and many more. The motor system of these products are very efficient and require less maintenance.

PTFE membrane 17 L/min <3.5 <4; Fe and Ca <0.5; Na <1.5; all other individual metals <0.3 <25 UPE membrane 8 L/min ≤30 <30 <50 PTFE membranes of a similar nominal pore rating show a better flow performance. This is a particularly attractive feature for

membrane. For example, PTFE membranes can be directly modified with Al2O3 through ALD without any pre-treatment (Fig. 2a).26 The underlying mechanisms of Al2O3 deposition are different for the inert PTFE surface compared to other membranes with polar

Hydrophobic PTFE membrane • Increases surface area • Improves flow • Minimizes pressure drop All-PTFE fluoropolymer materials and thermally bonded construction • Ensure excellent chemical compatibility • Minimize chloride and metals extractables that

2019/6/1 · In order to introduce the functional materials modified with maleimide by the DA reaction, the surface modification process of the PTFE membrane is required. For the amine surface modification of the PTFE membrane, it was irradiated with UV light (200 W, λ max = 254 nm) for 48 h under hydrazine vapor conditions, as shown in Fig. 1.

Fig. 2a and b shows the typical morphology of the pristine commercial PTFE membrane that exhibit a porous structure with fibers interwoven to form micropores (a mean pore size of 0.45 µm).After spray coating, a relatively dense layer of Fe 3 O 4 /PANI composite was deposited on the PTFE membrane surface (Fig. 2c), which increased the membrane thickness from 173 to 221 µm.

2017/5/9 · TOOLS & RESOURCES. Title: Porous PTFE membranes for metal removal. United States Patent 9855534. Abstract: Disclosed is a porous membrane comprising a porous polytetrafluoroethylene (PTFE) substrate and a coating comprising a copolymer of formula (I): H—[—O—CH(Rf)—CH2—]m—[—O—CHM-CH2—]n—[—O—CHL-CH2—]s—OH (I), wherein Rf is perfluoro

2021/7/23 · The PBI membrane and PBI/PTFE composite membrane prepared from the PBI/DMAc/LiCl solution with a [LiCl]/[BI] molar ratio of ~8.0 were used to dop H3PO4 and prepare membrane electrode assemblies (MEA).

2014/5/19 · It indicates that SPEEK/PTFE composite membrane has lower vanadium ion permeability than the SPEEK one. In addition, VRB from PEEK/PTFE composite membrane shows higher VE (89.6 ± 1 % vs. 86.7 ± 1 %) and EE (86.7 ± 1 % vs. 82 ± 1 %) compared

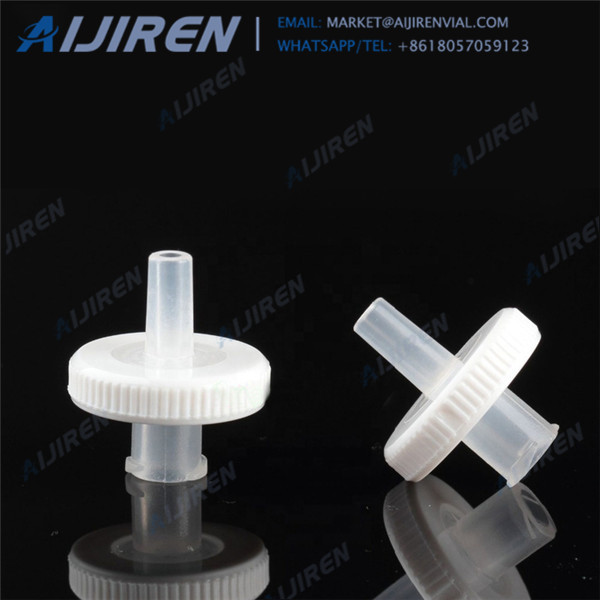

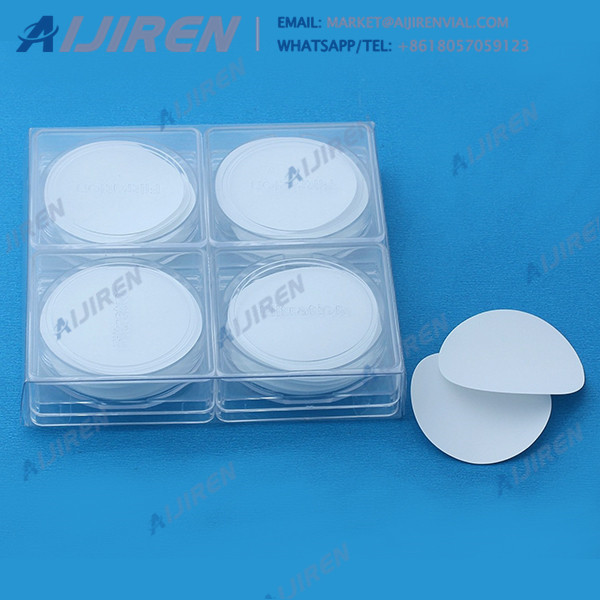

Filter Membrane: PTFE Surface Type: Hydrophobic Prefilter: No Porosity: 2µm Filter Diameter: 25mm Pack Size: 200 CONTACT YOUR SALES REPRESENTATIVE TO REQUEST A SAMPLE PACK. Syringe Filter-UltraClean for Metals, 25mm, 2µm, 200pk | Syringe Fil

Also disclosed is a method of preparing the porous membrane and a method of filtering a fluid, such as isopropanol, containing dissolved metals at a low concentration by the use of such membrane. Porous PTFE membranes for metal removal

2020/8/14 · By using low pressures and membrane filters with bigger-sized pores, nanofiltration a be used in treatments performed for drinking water such as eliminating heavy metals and softening water. The procedure of ultrafiltration is widely used only for protein separation and cold sterilization in the pharmaceutical industry, but also for wastewater cleaning and metal recovery in the field of