Fluorofil Plus High Flow Sterile Gas Filter with ePTFE Membrane Fluorofil F100 PTFE Membrane Cartridge Filters Hydrofil Nylon 6.6 Membrane Filter Hydrofil Plus Dual Nylon 6.6 Layer Membrane Cartridge Filters Vinofil Double Layer Membrane Filter

2019/5/22 · By coupling the pre-charged membrane (Fig. 3a) and the pure grounded membrane (Fig. 2a) together, a combined energy generation system can be realized, as seen in Fig. 4a.

Features of SOLAFT Filter Bags. Fabric filters to separate particulate with a high degree of efficiency. Range from ambient to 260⁰C maximum operating temperature. A broad range of chemical environments. Industrial applications including. Alumina, aluminium, coal-fired power generation, cement, coal processing, food and beverage, metals and

Multi-Purpose Filter for Small-Volume Venting and Gas Filtration PTFE membrane and polypropylene housing have broad chemical compatibility Disposable - Eliminates the cost and labor associated with disc-loaded stainless steel filter holders Autoclavable

PTFE Syringe Filters, 0.45 µm (250/pkg 750/cs)PTFE Syringe FiltersNon-Sterile Syringe Filters Pall Corporation is a filtration, separation and purification leader providing solutions to meet the critical fluid management needs of customers across the broad spectrum

polymers Article Waterproof-breathable PTFE nano- and Microfiber Membrane as High Efficiency PM2.5 Filter Xiao Li 1,†, Xiao-Xiong Wang 1,†, Tian-Tian Yue 1, Yuan Xu 1, Ming-Liang Zhao 2, Miao Yu 1,3, Seeram Ramakrishna 1,4 and Yun-Ze Long 1,* 1 Collaborative Innovation Center for Nanomaterials & Devices, College of Physics, Qingdao University,

Our PPS filter bag with PTFE membrane can reach 10mg/m 3 Applications: 1. Power Station (zibo) Design and supply PPS filter bags for zibo XX power station in 2013, Emission concentration:<12mg/m 3 2. Power Station (shanghai) Design and supply PPS 3

PTFE Membrane Filter Cartridges are carefully constructed for the Bio-pharma, beverage and fine chemical industries to provide secure reliable filtration. They are designed to completely remove bacteria, viruses, and particles from air and gas streams, even in the presence of humidity and moisture.

50 mm Filters with Superior Performance for Demanding Applications. Reusable and autoclavable. PTFE membrane and polypropylene housing have broad chemical resistance. Large surface area provides greater throughput and high air flow rate. Available with a variety of inlet and outlet connectors. 8 Part numbers available.

2019/7/25 · Figure 2 shows a set of characterization results on the PTFE nanofibrous membrane. Similar to the precursor PTFE-PEO sample, the PTFE nanofibrous membrane consists of only PTFE phase. As shown in Fig. 2a, there are two diffraction peaks located at 18.2 and 31.7 on the XRD pattern, corresponding to the (100) and (110) planes of PTFE respectively.

.jpg)

Our ePTFE membrane is a very thin, porous layer that prevents particulate matter from entering the body of the filter bag. Without the ePTFE membrane, particulate matter will penetrate the conventional filter, making it weaker and more resistant to airflow, especially over time.

The PHFZ-II (4+3) is 40″ and 30″ welded, with an integral cage outer diameter of φ69. ⑥Pleated Cellulose Filter Cartridge. Pleated Cellulose Filter Cartridge is economical, yet highly effective for general water filtration purposes. It can capture 20 sediment filter particulates down to nominal 20 microns in size.

Made of either color-coded UHMWPE or PVDF, the full flow filter offers increased surface area to optimize filter life and prevent clogging. The filter can be used with 1/8' cannulas and are available in packs of 100 or 1000. Certificates of analysis can be provided on request. Dissolution Sampling &

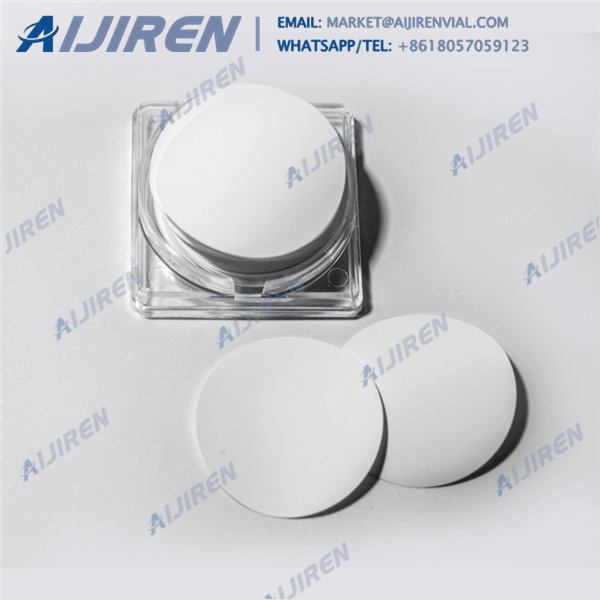

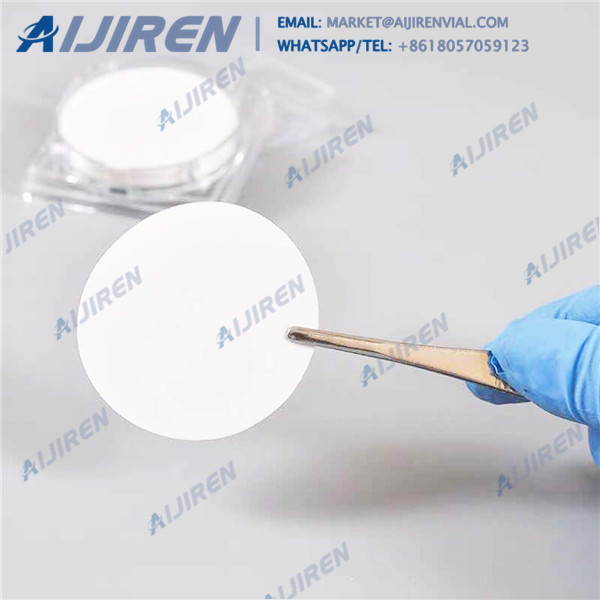

Aijiren Captiva filtration products for sample preparation provide reliable results for a wide range of tests and applications as well as repeated analyses. Our sample filtration products include syringe filters with a complete membrane portfolio for all sample types, filter plates, cartridges, and more.

this approach can also be effectively exploited for boosted power generation with realistic future applications. 1. Introduction Once the succeeding water droplets were in contact with the PTFE membrane at regular intervals of time (Fig. 5e–h Fig. 5 ...