The Chemflow®-PE filter cartridge uses a PTFE pleated membrane filter cartridge along with HDPE supports that provide an economical alternative to all-fluoropolymer cartridges while providing a high degree of retention and cleanliness.

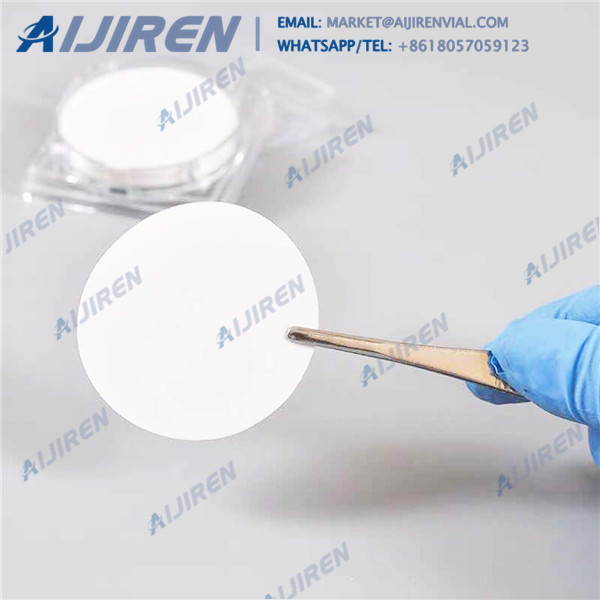

Description of PTFE Membrane Filters PTFE membrane filter is made of polytetrafluoroethylene ultrafine fibers by hot-melt bonding together. Difference from glass fiber membrane, PTFE filter is a kind of membrane material for deep filtration.Membrane filter disc has the following characteristics: membrane filter 0.22 μm is produced from food-grade isotactic polypropylene.

PVDF Membrane Filters. PVDF (polyvinylidene fluoride) is a hydrophobic, solvent resistant membrane that is known for it's high temperature resistance and high particulate removal efficiencies. PVDF is commonly used in the offshore oil and plumbing industries, and is suitable for Gas, Vapor, High-Temperature, Food, and Medicine Filtration.

PTFE has a low coefficienct of friction resulting in good cake discharge during pulse cleaning. A common trade name is Teflon. PTFE can be applied to filter media as a membrane thermobonded on needled felts as an available standard.

Membrane Hydrophilic PTFE PVDF Nylon Pore size (µm) 0.20 0.45 0.22 0.45 0.20 0.45 Diameter (mm) 13 17 25 Filtration area Glass Filter Holder w/ PTFE Seal 47mm, PTFE support, 300mL funnel 351620 Polysulfone Aseptic Holder 47mm, 300mL 311420 ...

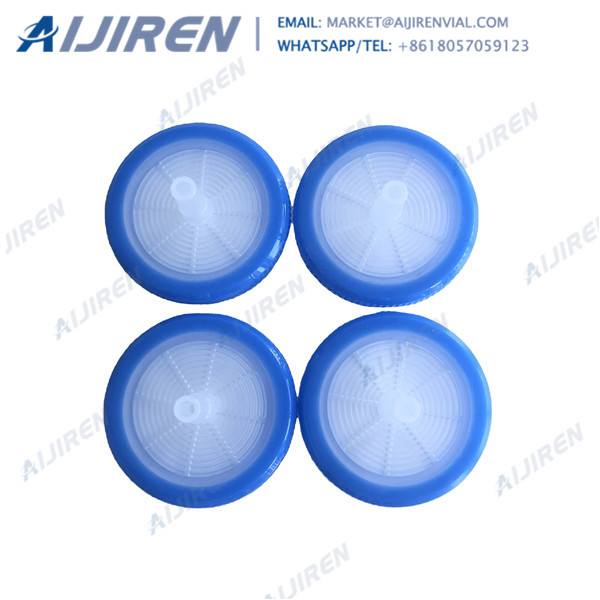

EZFlow 25mm, 47mm, and 90mm membrane disc filters are used to retain particles or microorganisms by surface capture. The membrane disc filters are available in 0.22µm or 0.45µm pore sizes. The Hydrophobic PTFE membrane is bonded to a polypropylene support and due to its extreme chemical.

PTFE Membrane Filter Cartridge – UPTFE Series It is constructed of hydrophobic Polytetrafluotoethylene membrane media for your critical application. Hydrophobic PTFE Membrane media High flow and low pressure drop No fiber release 100% integrity tested FDA compliance material.

PHILOS Co. Ltd. manufactures and produces different ranges of high-quality membrane modules, which is based on more than 20 years of experience in membrane and water filtration industry. PHILOS is one of the largest providers of membrane for many PHILOS Wellspring - Non-Powered Membrane

Find ptfe filters and related products for scientific research at MilliporeSigma Product Number Product Description SDS SLLG033 Replaces SLLGH25NK, 0.20 µm pore size, 33 mm diameter, Millex-LG hydrophilic PTFE membrane

Pore size ratings: Our microfiltration media are offered in a range of membrane filter pore sizes, from 30 nm (0.03μm) to 10μm. Pre-filter and final filter: With various pore size ratings, our membranes support both pre-filter (1.0–10.0 μm) and leading-edge final filter (30 nm–200 nm) applications.

.jpg)

Tetratex is a proprietary expanded microporous PTFE (Polytetrafluoroethylene) membrane, manufactured solely by Donaldson Membranes. It is laminated to a variety of base substrates to provide a complete range of media including woven and felted textile media for conversion into all types of filter bag as well as pleatable media for cartridge style elements.

PTFE Laminated Membrane Filters. These hydrophobic PTFE membrane filters are laminated onto polypropylene netting for improved strength and handling. Due to broad chemical compatibility and excellent water repellency, they are ideal for solvent filtration, phase separations, venting, and air sampling. Read More.

Mikrotex® Expanded PTFE Membrane Filter Media • Longer service life: The nonstick, hydrophobic PTFE surface promotes dust cake release thereby reducing cleaning frequency and duration. Less wear and tear on the filter bags and equipment means

Milliseal Membrane Seal, PTFE, 18 mm. This is a 18 mm Hydrophobic PTFE Membrane Filter with a 0.45 micron pore size. For use in Sterilizing filtration, bioassays, solvent filtration.

Foliar fertilizers Bio-fertilizers MS ® PTFE MEMBRANE FORMAT Roll(Width≤500mm) A4 and A5 sheets Die cut parts with adhesive backing ASSEMBLY OPTIONS FOR MS ® PTFE VENTS Ultra-Sonic welding or heat sealing require welding of the vent