The PTFE membrane works as the primary filter cake, collecting all of the particulate on the surface. This keeps the particulate from penetrating the filter fabric, which can lead to reduced airflow, and filter

MATERIAL COMPLIANCE USA All components of the PT N filter element are FDA listed for food contact use in the Code of Federal Regulations (CFR), Title 21. INDUSTRIES AND APPLICATIONS MATERIALS CFR TITLE 21 Membrane PTFE 177.1550

This study shows the feasibility of using electrospinning technique to prepare polytetrafluoroethylene/poly (vinyl alcohol) (PTFE/PVA) nanofibers on PTFE microfiber membrane as substrate. Then, PVA in the fiber membrane was removed by thermal treatment at about 350 °C. Compared to PTFE microfiber substrates, the composite PTFE fiber membranes (CPFMs) have

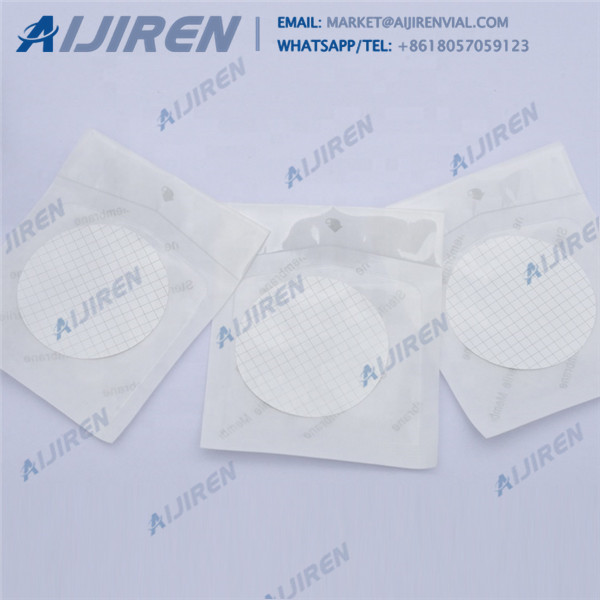

PTFE PM2.5 Air Monitoring Membrane Filter, 46.2mm with support ring, 2.0 um, 50 per pack, SF18040 Regular Price: $454.25 Price $336.00

15/7/2021 · Ultrafine PTFE porous fibrous membrane was fabricated. • The porous structures can be controlled. • Ultralow air resistance (89.9 Pa) and high filtration efficiency (99.72%). In order to solve the problem of air pollution, especially in high temperature environment, an

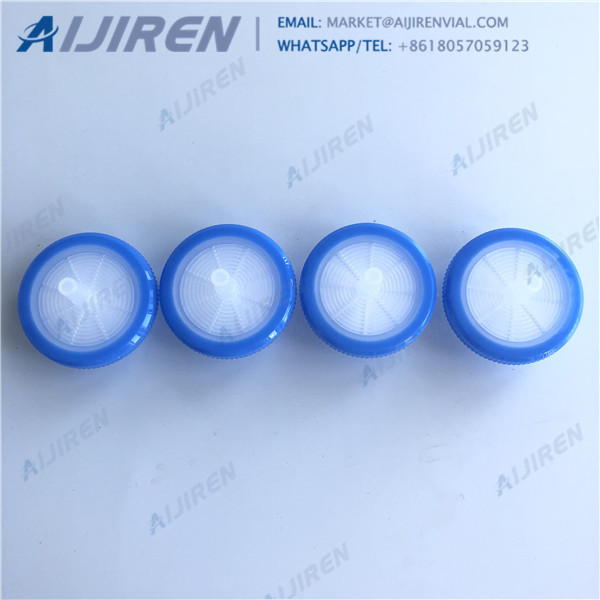

Membrane filter AISIMO provides a wide selection of membrane materials for the microfiltration with different pore sizes Typical applications for membrane filters are cell retention, particle collection, clarification and sterile filtration of aqueous solutions, particulate analysis, microbiological analysis and epifluorescence microscopy.

PES membrane filter does not adsorb proteins and extracts and does not pollute the sample. Hydrophilic polyethersulfone has low protein adsorption and high drug compatibility. PES microfiltration membrane is specially designed for biochemical, inspection, pharmaceutical, and sterilization filtration devices.

MS ® PTFE membrane offer excellent control over pore size, porosity, permeability and thickness.Designed to help deliver precision, accuracy and reliability. MS ® PTFE Materials exemplify the critical design standards required in many challenging filtration and textile.

Tetratex is a proprietary expanded microporous PTFE (Polytetrafluoroethylene) membrane, manufactured solely by Donaldson Membranes. It is laminated to a variety of base substrates to provide a complete range of media including woven and felted textile media for conversion into all types of filter bag as well as pleatable media for cartridge style elements.

PTFE membrane CS compact filter of filtering class H13 is composed of 3 layers including 2 outer protective polyester layers and 1 layer of PTFE membrane in the middle. This filter is particularly used in buildings in which installations are not designed to install standard HEPA filters which have higher pressure drop. Frame: Plastic.

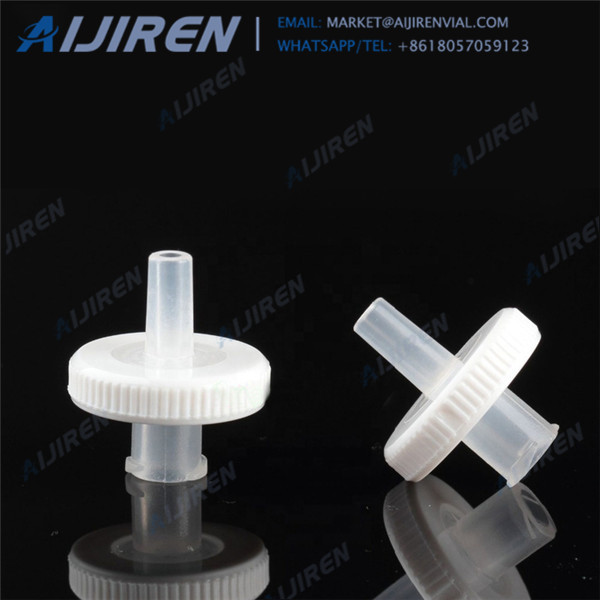

Emflon PFR filters provide high assurance of filter integrity and long life, even during continuous use in hot air up to 60 C, in vent applications up to 80 C and during repeated steaming. These PTFE filter cartridges can withstand up to 1 bar (14.5 psi) differential

PTFE Laminated Membrane Filters. These hydrophobic PTFE membrane filters are laminated onto polypropylene netting for improved strength and handling. Due to broad chemical compatibility and excellent water repellency, they are ideal for solvent filtration, phase separations, venting, and air sampling. Read More.

Manufactured with AAF Flanders’ eFRM expanded FlouroResin Membrane media and an innovative tapered aluminum separator design, MEGAcel I eFRM filters are the industry’s highest performing HEPA filter. Optimize system efficiency, strength, and integrity, while

PTFE membrane discs are perfectly suited for laboratory scale filtration of aggressive organic solvents, concentrated acids, alkalis, and cryogenic fluids, which would attack other filtration membranes. They are also well suited for air sampling and particulate