The patented* Porex Tubular Membrane Filters are designed to fit new and existing tubular membrane systems. In operation, a fluid, such as chemically pre-treated wastewater, flows through the cross flow membrane tubes at high velocity, sufficient to maintain turbulent flow. At typical operating pressures of 20–80 psi, clean fluid is forced

2020/5/27 · To address ongoing concerns around potentially harmful perfluorooctanoic acid (PFOA) and PFOA-related compounds, Porex, a specialist in porous polymer solutions, is offering Virtek PTFE, a 100% pure PTFE membrane, and Oxyphen’s family of track-etched

2011/12/8 · Gore develops PTFE membranes for high-purity chemicals. The membranes from W L Gore have improved retention and flow performance, and all non-PTFE components use HDPE to allow for low organic and metal ion extractables. The HDPE family of cartridge filters will be available in three retention ratings – 0.1 µm, 30 nm and 20 nm.

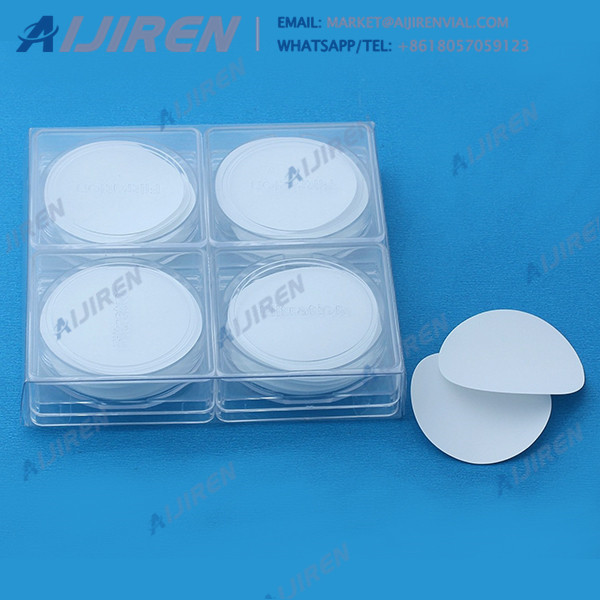

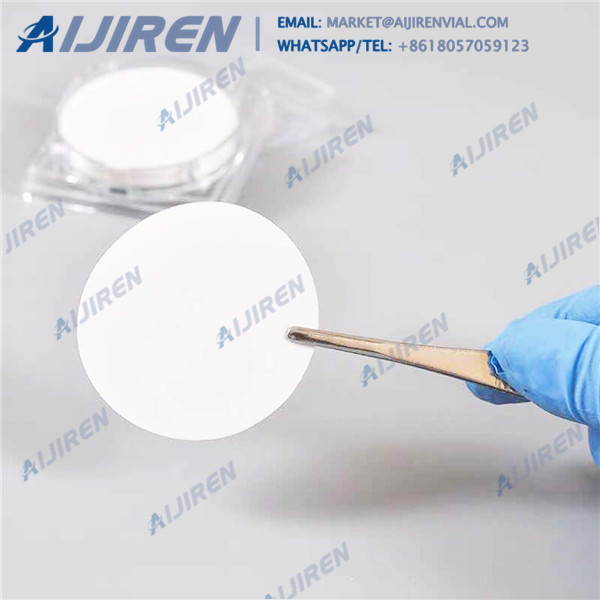

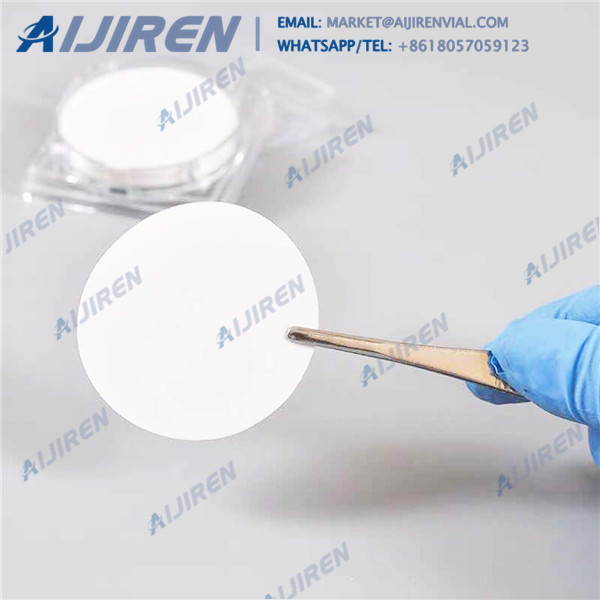

PTFE (Polytetrafluoroethylene) Membrane Filters. PTFE filters are the versatile choice for size-selective samplers. The material’s unique properties make it ideal for gravimetric, chemical, and/or microscopic analysis of sample particulate. PTFE filters are used for aerosol sampling, air venting and gas filtration.

Porex is a micro-expanded PTFE product that allows gasses to permeate but has a high barrier for liquid water. Porex can be used in instances where gas permeation is desired, but liquid is not. This material is perfect for vents, gas/liquid separation membranes, etc.

Custom PTFE membrane filters are used for venting applications, phase separations, aerosol samplings, and the liquid filtration of aggressive chemicals such as strong acids. Additional applications include air filtration in microelectronics facilities, equipment venting, and solvent filtration.

2021/7/15 · Ultrafine PTFE porous fibrous membrane was fabricated. • The porous structures can be controlled. • Ultralow air resistance (89.9 Pa) and high filtration efficiency (99.72%). In order to solve the problem of air pollution, especially in high temperature environment, an

Vacuum membrane filter 0.45 μm is usually not used for air, gas, or exhaust filtration because if they get wet accidentally, for example through condensation, the filter will block the flow. The hydrophobic PTFE membrane filter disc is modified to obtain a hydrophilic PTFE membrane, which can be suitable for filtering aqueous solutions and organic solutions, and has better chemical resistance.

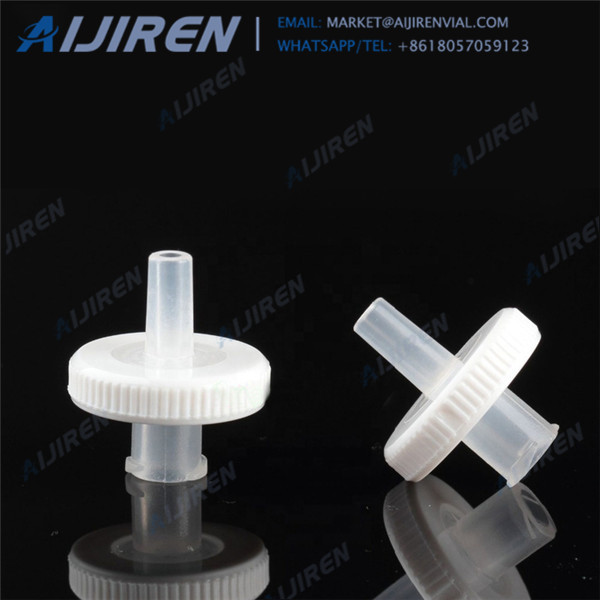

Description: PTFE Absolute Rated Membrane Filter Cartridges Polytetrafluoroethylene ( PTFE) membrane filter cartridges constructed in polypropylene hardware for a wide range of industrial applications Absolute retention from 0.1 to 1.0 microns Outstanding hydrophobicity. Assembly / Element Type: Cartridge, Other. Features: FDA Compliant.

2020/8/16 · The demo shows the toughness and durability of Porex Virtek sintered PTFE versus alternative cast and non-woven membranes that require chemical treatment to

2. Decide an appropriate pore size. The pore size of a filter, stated in microns (aka micrometers or µm), is determined by the diameter of particles retained by the filter or by a bubble point test. Fun fact: Due to viscosity differences, a 0.2 micron pore size rated membrane in liquid can retain up to 0.02 micron particles in air. What size

PTFE membrane filter for exhaust air of vacuum toilet system United States Patent 6681412 Abstract: A filter arrangement for a vacuum toilet system includes a filter element arranged in a filter housing connected to a waste water tank of the vacuum toilet

Filtration membranes may be composed of nylon, polypropylene, cellulose, nitrocellulose, glass fiber, and PTFE. Nylon filtration membranes are chemically compatible with a wide range of solvents. Polypropylene filtration membranes are used with more aggressive solvents. Because these membrane filters are highly adsorbent, they’re also a good