PES membrane provides broad chemical compatibility across a wide pH range (1–14) Pro cessing. Essential Process Requirements. Sterile Filtration.

Filter both aqueous and organic solvents Optically clear when wet Hydrophilic PTFE membranes are a thin, unsupported, highly porous film that offers maximum

Syringe Filters Solvent Compatibility Chart Top 10 Reasons to Use Restek Syringe Filters ... Chemical Reagents. Cellulose. Acetate. Nylon. PES. PTFE.

Mar 8, 2017 The filter membrane may be of PTFE, nylon, or other treated products for specific purposes. Most manufacturers publish compatibility wall ...

Custom manufacturer of membrane filters for baghouses. Suitable for applications up to 500 degrees F with moisture and chemical resistance feature. Serves the

CHEMICAL COMPATIBILITY TABLE. For ChemQuik®, DrumQuik®, DrumQuik PRO & Other Common Colder Series Coupling Materials. (Updated 01/14/2010). Swelling.

In special circumstances, we will adopt to use different filter material of sewing thread, the suture properties such as strength, heat resistance and chemical

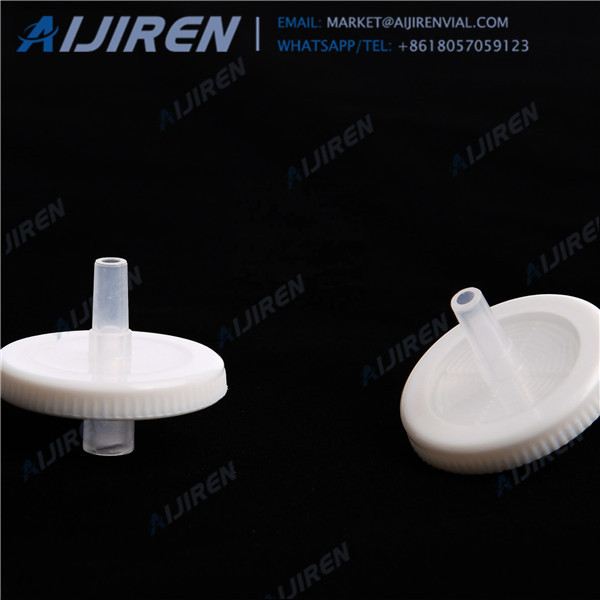

Phenex Syringe Filters, HPLC syringe filters, GC syringe filters, PTFE syringe filters, nylon syringe filters.

Filter membranes for filtering organic solvents and aqueous solutions for HPLC and (PTFE) membranes have high strength and broad chemical compatibility, ...

Supplier: Pall Laboratory. Description: Next generation of universal hydrophilic PTFE membrane with maximum chemical compatibility when filtering both

Use this reference to determine chemical compatibility of different membranes and elements.

CHROMAFIL® syringe filters are used for filtration of suspended matter from ited resistance towards THF. Solvent. Material. MV CA RC. PA. PTFE H-PTFE ...

.jpg)

The extreme chemical resistance of PTFE membranes makes optimize the filtration pro cess by keying on the two most important areas – maximizing filter ...

Johnson Test Papers' PTFE Syringe Filters are purpose built with features designed to It has excellent compatibility with aggressive solvents and acids.

This guide was compiled from information provided by material suppliers and manufacturers. A = Excellent, B = Good, C = Fair to Poor, D = Not recommended. X or