POREX Virtek™ sintered PTFE membrane is UL 94 V-0 and UL 746C listed, tested to meet all IP ratings, and can meet NEMA or other test standards. Minimizes condensation and prevents the entry of dust, dirt, water and other contaminants. POREX® vents are UV and weather resistant, chemically inert, thermally resistant, UL-listed.

2021/4/14 · Global PTFE Venting Membrane Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2025, a new addition to the catalog of MarketQuest.biz, contains a set of essential analyses related to the values as well as existing business scenarios available in the industry.

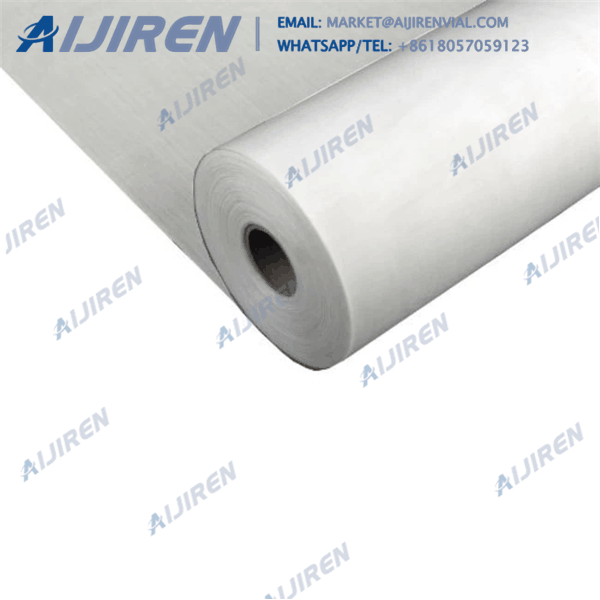

DIFFUSION MEDIA SUPPORT FILTRATION VENTING POREX® Porous PTFE Materials Features • Standard pore sizes from 1µ to 50µ (by Bubble Point) • Standard roll width 330mm • Available conversions: sheets, slit rolls, die-cut parts, rotary cut parts and adhesive discs

with PTFE Membrane with Glass Laminate with Emflon® II Membrane 217_P_Acro37Tf.tif 197_P_BacterialAi.tif 211_P_Acro50_EmFl.tif Key Features •Ideal for small-volume venting, •Hydrophobic, glass laminate media •Made with proprietary, low pressure

Porex is the original producer of porous plastic nibs for the writing instrument industry especially highlighters and children’s coloring markers. The Nibs can be custom-designed using special material formulations to optimize marker system requirements. Nibs for White board markers, indelible inks etc. can also be produced.

POREX VIRTEK® PTFE MEMBRANE Comparison to Pall® Versapor® R & Versapor® membranes If you need an alternative to the discontinued Pall ® Versapor R or Versapor ® membrane, make the switch to POREX Virtek membranes for added benefits that

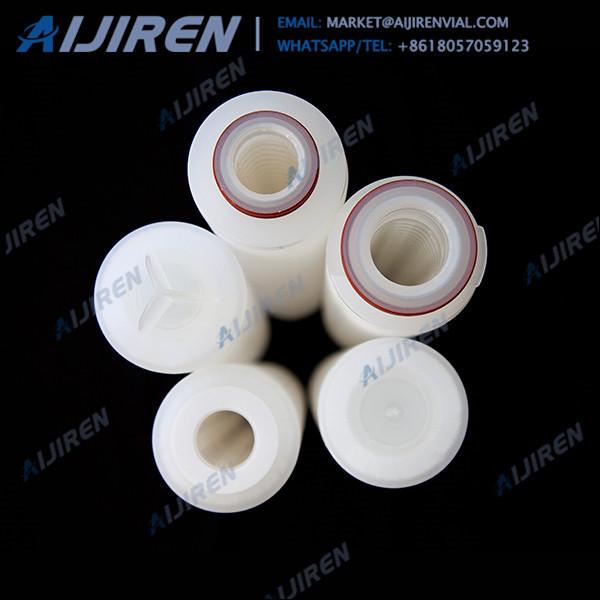

POREX PTFE vents for IP-rated enclosures are an effective and low-cost industry recognized solution using a single-component membrane that reduces installation cost and time. The inherent membrane strength ensures reliable and repeatable performance;

Porex PTFE materials offer excellent control over pore size, porosity, permeability, water intrusion pressure and thickness. Designed to help deliver precision, accuracy and reliability, Porex porous PTFE materials exemplify the critical design standards required in many challenging filtration, venting, diffusion and media support applications.

2020/5/27 · Both the Porex and Oxyphen technologies offer venting material which can be used in the automotive, electronics, healthcare and industrial markets. Developed using a proprietary PTFE sintering process, the Porex Virtek PTFE features an intricate network of open-celled, omni-directional pores that enable critical passage of small molecules such as air and water vapour while being naturally

Porex PTFE materials offer excellent control over pore size, porosity, permeability, water intrusion pressure and thickness. Designed to help deliver precision, accuracy and reliability, Porex porous PTFE materials exemplify the critical design standards required in many challenging filtration, venting, diffusion and media support applications.

Porex is a micro-expanded PTFE product that allows gasses to permeate but has a high barrier for liquid water. Porex can be used in instances where gas permeation is desired, but liquid is not. This material is perfect for vents, gas/liquid separation membranes, etc.

POREX Virtek IP-rated PTFE vents for sealed enclosures are designed to provide ventilation, pressure equalization and protection from dust, water and fluids. † IEC std.

Millex Syringe Filter, Fluoropore® PTFE, Hydrophobic, Non-sterile 0.20 µm pore size, 25 mm diameter, Millex-FG hydrophobic PTFE membrane, for gas filtration and venting applications; find Millipore-SLFG02550 MSDS, related peer-reviewed papers, technical

Protection vents and filters from Porex help renewable energy systems run more reliably. Our vents repel water, dust and dirt, and allows the device to breathe during heating and cooling cycles. Our filters can be customized to filter fluid or air, depending on the application. Compared to competitive vents, our POREX Virtek ® PTFE …