PTFE membranes and seals provide device manufactures with a consistent, chemical compatible and temperature barrier to microbes and particulate matter. PTFE is a class of thermoplastic polymer which possess tremendous properties like enhanced flexibility, heat resistance, self-lubricating properties, waterproof and strength.

Microporous Membrane. Microporous membranes rely on diffusion through the air in the pores, a much faster process than solution-diffusion through PDMS, (Campbell Ritchie et al., 1996) and it can be seen from Table II.5.5.3 that a microporous membrane with a typical porosity of 30–40% and thickness of 30 μm will have a much higher gas flux than a homogeneous membrane of similar thickness

PTFE diaphragms, also referred to as membranes, are air-tight seals between two spaces with product and pressure, which typically differ from each other. Commonly used in pumps for the chemical and petrochemical industry, food and beverage industry and the pharmaceutical industry. This type of diaphragm or membrane is manufactured according

Polymeric gas-separation membranes were commercialized 30 years ago. The interest on these systems is increasing because of the simplicity of concept and low-energy consumption. In the refinery, gas separation is needed in many processes such as natural gas treatment, carbon dioxide capture, hydrogen purification, and hydrocarbons separations. In these processes, the membranes have proven to

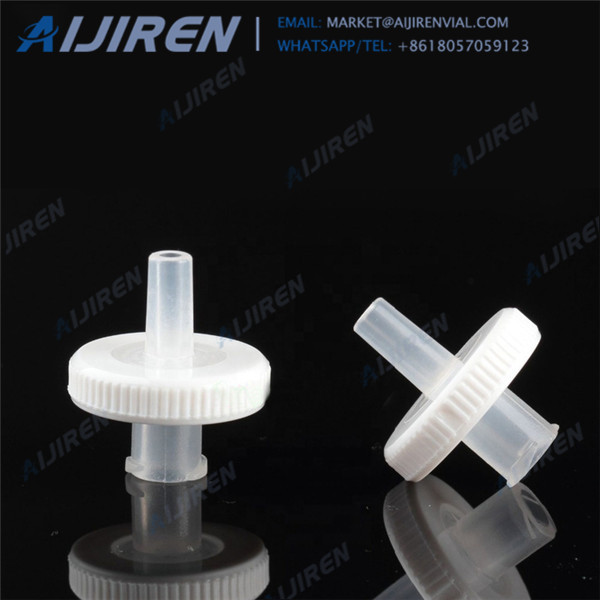

KALIS-TF. KALIS Series – Polytetrafluoroethylene (PTFE) Hydrophobic Membrane with PP Hardware. Product Information. Description. Hydrophobic Membrane with PP Hardware. Applications. Air, Gas & Vent Filtration; Sterile Barrier, Bio-Burden Control, Fermentation, Sparging. Micron Rating (mm)

Acro® 50 Vent Devices with PTFE Membrane. 50 mm Filters with Superior Performance for Demanding Applications. Reusable and autoclavable. PTFE membrane and polypropylene housing have broad chemical resistance. Large surface area provides greater throughput and high air flow rate. Available with a variety of inlet and outlet connectors.

e. Note – PTFE coated EPDM membranes should not be applied in any petrochemical applications as petrochemical attacks the base EPDM structure of the membrane. 10. Are there options to thin coated EPDM rubber membranes of 97% PU, 3% PTFE? a. Matrix™ - polyurethane PTFE membrane with 100% of product PTFE/PU compound.

Membrane Filters. Membrane filters serve as effective physical barriers that remove solids, viruses, bacteria, and other unwanted molecules. Specialized types are designed for softening, disinfecting, organic removal processing, and water desalination. The filters can be installed in compact, automated, or modular units.

The e-PTFE membranes are recognized as the principal tested membranes for GTR, especially Gore-Tex®. Reinforced Gore-Tex® membrane is e-PTFE reinforced with titanium. These e-PTFE membranes are available in various forms, thus they can properly maintain the space to be regenerated, and in case of exposure they are easily removed.

Nov 02, 2020 · ePTFE Membrane: The Market Is Scattered with Huge Potential. ePTFE membrane, a new type of polymer material, has a micron or sub-micron porous three-dimensional network microstructure, which is made of PTFE resin through special processing methods such as stretching and turning. While maintaining the excellent chemical properties of PTFE, it

Our unsupported, hydrophobic, PTFE membrane filters are ideal for sterilization and venting applications involving air, gasses, and solvents/acids incompatible with most other filters. Chemicals, Petrochemicals, and Fertilizers

Weldable Membranes. Venting membranes made from porous PTFE can be excellently welded on plastic parts, thermally or using ultrasonic technology. Welding enables a highly durable connection between the membrane and the component, even under harshest conditions. The membranes ensure reliable venting and protect the housing against penetrating

PTFE, FEP, and Nylon tubing materials feature mechanical properties ideally suited to consistently perform in the harshest conditions. Though there are several distinctions among the materials, they do share some similar properties and are relatively chemically inert. The material can be fabricated to any specification or form, too.

Polytetrafluoroethylene (PTFE) is suitable for industries such as chemical, petrochemical, oil refining, chlor-alkali, acid production, phosphate fertilizer, pharmaceuticals, pesticides, chemical fiber, dyeing, coking, coal gas, organic synthesis, non-ferrous smelting, steel, atomic energy and polymer filter materials, Production of high-purity

PTFE flat sheet membranes are perfect for Membrane Bioreactors (MBRs) systems treating municipal wastewater, and wastewater from industries such as Power plants, steel mills, petrochemical plants, textile plants, landfill leachate, etc. The PTFE membrane material affords users the best protection for membrane applications with very high or very