Jun 14, 2016 Plastic contamination frequently occurs due to particles from the ... of membranes used (polycarbonate, polytetrafluoroethylene (PTFE), ...

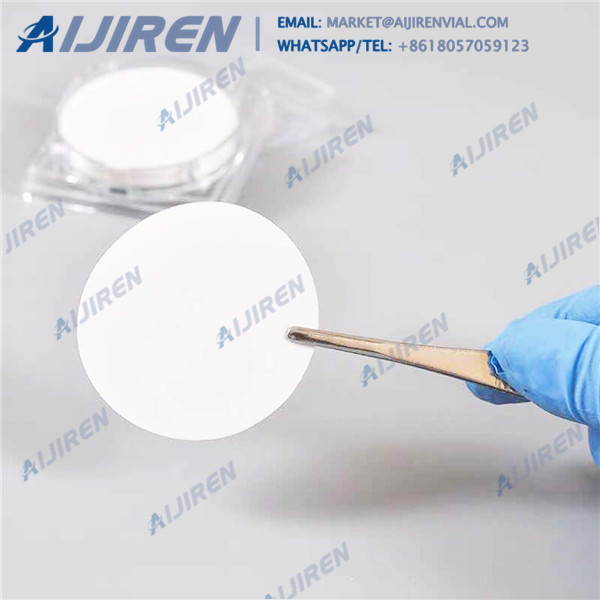

Polytetrafluoroethylene (PTFE) membranes have high strength and broad chemical compatibility, and are commonly used to clarify aqueous solutions,

What Chemicals are Compatible with PTFE and Teflon®*? PTFE is the most versatile plastic in terms of chemical compatibility; Highly resistant to most acids,

¹Division of Cardiovascular Surgery, Jichi Medical University, Japan Although the e-PTFE membrane is effective and useful for repeat sternotomy, ...

Jul 5, 2011 A membrane protein is directly produced and incorporated into the polymer membrane. Synthetic cell membranes invented at the Institute of ...

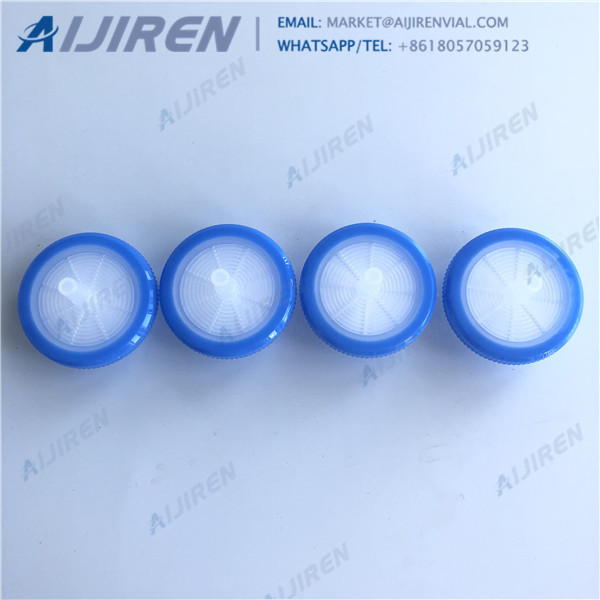

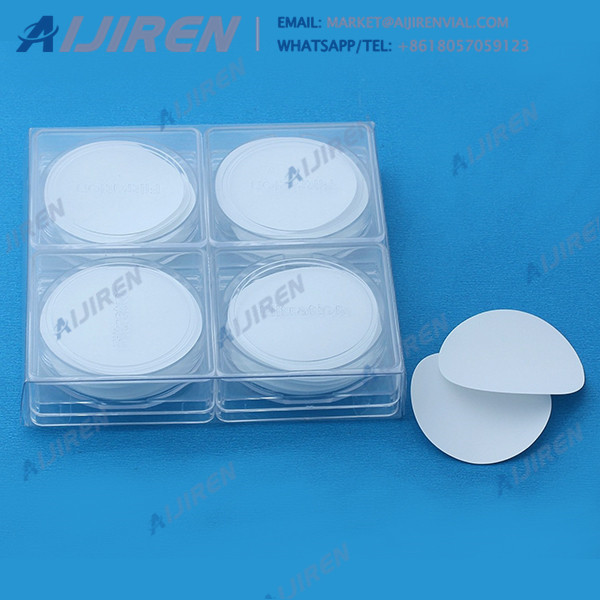

Properties of membranes differ markedly based upon their composition, fabrication method, surface treatment, and pore size. Membrane Filter Characteristics

Aug 23, 2019 ePTFE, a non-woven, open pore fluoropolymer plastic, is suitable for the critical demands of medical applications and other industries.

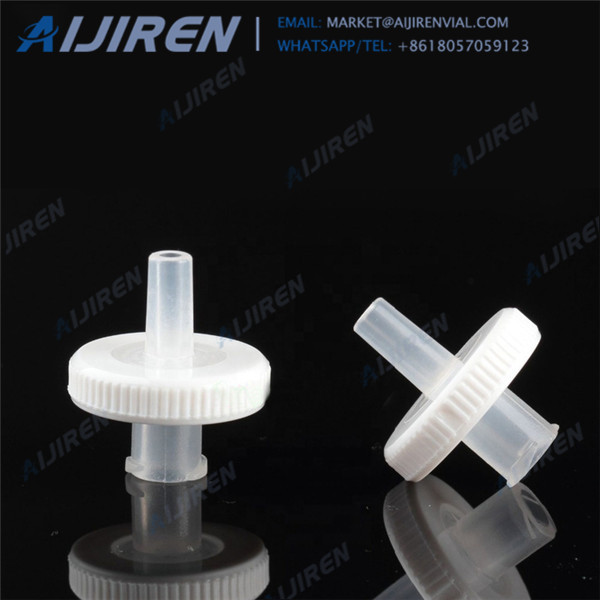

We had produced a custom plastic casing and bonded Finetech's highly breathable hydrophobic PTFE membrane for the purpose of blocking out moisture and dust,

Polytetrafluorethylene (PTFE) membranes are naturally and permanently in the filter funnels and storage bottles for the Corning plastic vacuum filters.

Oct 26, 2020 Blue surgical face masks, like the ones featured in the Facebook post, are most commonly made out of a different type of plastic called ...

the electronic processing, pharmaceutical, medical, chemical, and food and beverage markets. ... MMF Series - PTFE Membrane w/ PP Components (Miniature).

4 Medical and Biological Uses. ePTFE membrane films are hydrophobic and oleophobic, making them a good fit for medical applications. When formed into membranes,

Aug 21, 2020 Plastic bags, tires, disposable cups, plastic straws, PET bottles are ... In their studies related to the development of PTFE membranes for ...

PTFE Membrane. GVS Laminated PTFE filters are made of a polytetrafluoroethylene polymer (PTFE) laminated to a polypropylene support for improved durability and

Additives like PTFE and silicone are commonly used to improve lubricity and wear resistance of a plastic material. Manufacturing feasibility: This is another