Protect people, protect the environment, protect the product — in manufacturing, controlling contamination is a must. Gore provides reliable air, gas, liquid and particle filtration solutions that purify processes, increase yields and control costs.

2020/2/5 · Logan, B. E. & Elimelech, M. Membrane-based processes for sustainable power generation using water. Nature 488 , 313–319 (2012). CAS Article ADS Google Scholar

2021/7/30 · New York, July 30, 2021 (GLOBE NEWSWIRE) -- Reportlinker.com announces the release of the report "PTFE Membranes Market Research Report by Membrane

Since 1958, Gore has developed products that improve lives. At the center of these solutions is polytetrafluoroethylene (PTFE), a polymer with exceptional properties like high tensile strength, a low dielectric constant, UV resistance and many more. In 1969, the possibilities for PTFE expanded with Bob Gore’s discovery of expanded PTFE, or ePTFE.

Global PTFE Membrane Market Research: Information By Type (Hydrophobic PTFE Membrane), The Application (Industrial Filtration, Textiles, Medical & Pharmaceutical, Architecture, Others) – Forecast Till 2027. Please note that the assessment period of report has been updated from 2017-2023 to 2020-2027. Cordially fill the sample form for updated

Pall Water, a division of Pall Corporation and a member of the Danaher portfolio of water companies, is the filtration partner of choice for companies who need smart water solutions. With more than two billion gallons of installed capacity spanning six continents, Pall Water is a leader in membrane-based water treatment solutions.

The PTFE membranes also referred as Polytetrafluoroethylene membranes. These are non-reactive filter media used in various applications that involves acids, bases, solvents, and different liquids. Also, they are used in the industrial applications such as mineral production, temperature, humidity, power generation, and chemical processing to monitor standards for quality of product and

Proton Exchange Membrane. Proton exchange membranes (PEM) are key electrolyte components in PEM fuel cells which, owing to their low operating temperature and high power density, are the most promising and versatile among the different FC technologies for low to medium power generation, especially under discontinuous or dynamic operation (e.g

2021/5/21 · The PTFE membranes also referred as Polytetrafluoroethylene membranes. These are non-reactive filter media used in various applications that involves acids, bases, solvents, and different liquids. Also, they are used in the industrial applications such as mineral production, temperature, humidity, power generation, and chemical processing to monitor standards for quality of product and

Pall joined Danaher in 2015 and is the company’s largest acquisition to date. Founded in 1946, Pall has a strong track record of innovation and performance. Since joining Danaher, Pall has continued to drive innovation, developing everything from a mobile water treatment portfolio to an advanced filtration membrane for wet chemical processing.

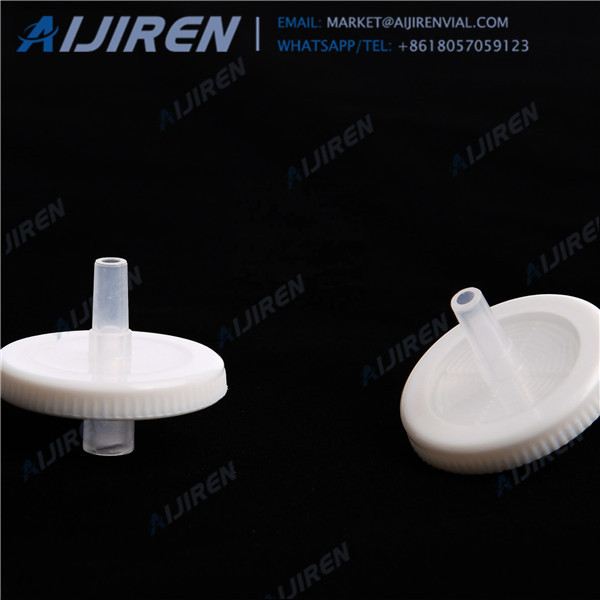

Emflon® PFR membrane filter cartridge, 0.2 µm sterilizing grade, 5-inch length, double-o-ring (ethylene propylene rubber) with bayonet lock and flat end. Product ID: AB05PFR2PVJ. Product ID. AB05PFR2PVJ. Unit of Measure. 1/EA. Min Order Qty.

The Membrane Filter (MF) Technique was introduced in the late 1950s as an alternative to the Most Probable Number (MPN) procedure for microbiological analysis of water samples. The MF Technique offers the advantage of isolating discrete colonies of bacteria, whereas the MPN procedure only indicates the presence or absence of an approximate number or organisms (indicated by turbidity in test

Proton-exchange membrane fuel cells (PEMFC), also known as polymer electrolyte membrane (PEM) fuel cells, are a type of fuel cell being developed mainly for transport applications, as well as for stationary fuel-cell applications and portable fuel-cell applications. Their distinguishing features include lower temperature/pressure ranges (50 to

PTFE Membrane Disc Filters - 2 µm, 47 mm (50/pkg) Product ID. R2PJ047. Material. PTFE with PMP (polymethyl- pentene) support ring. Air flow rate (0.7 bar (70 kPa,10 psi) 53 L/min/cm². Diameter. 47 mm.

Pall filter plates feature a rigid construction, which facilitates ease of use in automated systems. The rigidity of the plate prevents it from flexing and jamming in robotic processing units. Plates are constructed from chemically resistant and biologically inert polypropylene, which means that plates are themselves low in binding to nucleic acids and proteins.