Versapor Membranes are Still Alive and Better Than Ever! Our versatile hydrophobic grades offer a variety of benefits: Superior retention and air flow rate. Low pressure drop. Compatibility with Gamma, EtO, autoclave, and E-beam sterilization methods. ISO-10993 biocompatibility. Pall Corporation is committed to providing a complete line of

The use and re-use of sterilizing grade membrane filters, rated at 0.2 µm and even 0.1 µm, occurs often in nonsterilizing liquid-service applications such as those carried out for bioburden or particle reduction

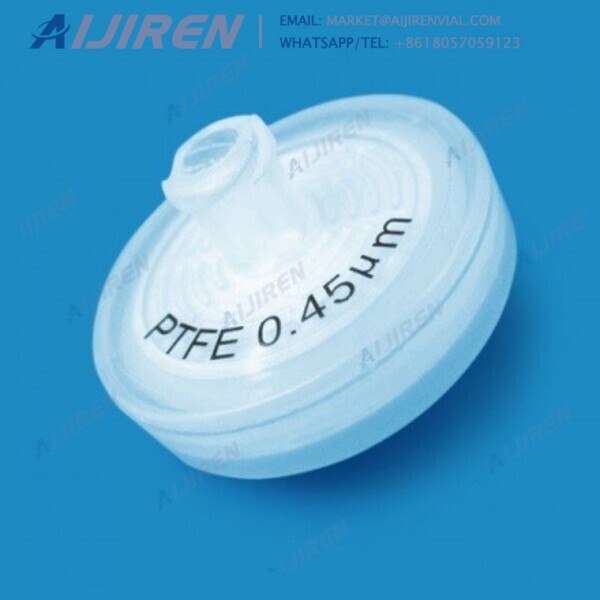

PTFE Syringe Filters, 0.45 µm (250/pkg 750/cs)PTFE Syringe FiltersNon-Sterile Syringe Filters Pall Corporation is a filtration, separation and purification leader providing solutions to meet the critical fluid management needs of customers across the broad spectrum

Emflon® PFR membrane filter cartridge, 0.2 µm sterilizing grade, 20-inch length, double-o-ring (silicone) with bayonet lock and fin end - Emflon® PFR membrane filter cartridge, 0.2 µm sterilizing grade, 20-inch length, double-o-ring (silicone) with bayonet lock and fin

PTFE microporous membrane pleated filter element is made of natural hydrophobic polytetrafluoroethylene (PTFE) membrane and polypropylene material parts by advanced hot-melt sealing technology in a controlled Class-100 clean environment without any adhesive and surfactant, and meets the technical requirements of the national standard of the

Ensuring the correct filtration membrane has been selected from different types of filter materials is often overlooked in routine laboratory sample filtration. Here, we explore different filtration properties and how to take a preventative—rather than reactive—approach, minimizing time spent troubleshooting and maximizing efficiency.

The ePTFE air filter membrane. The ePTFE air filter membrane is made of PTFE resin, which is specially processed, biaxially stretched, and has a unique node fibrility, smooth surface, chemical resistance, airtight impermeability, large air permeability, flame retardancy and resistance. High temperature, strong acid and alkali resistance, non

2021/7/8 · Understanding integrity testing for sterile filtration. A concise primer on testing methods for different applications. Part 2 of Pall’s 4-part filtration series. Basically, the naturally hydrophobic PTFE (Polytetrafluoroethylene) membrane resists water penetration. However

Membrane Filters. Membrane filters serve as effective physical barriers that remove solids, viruses, bacteria, and other unwanted molecules. Specialized types are designed for softening, disinfecting, organic removal processing, and water desalination. The filters can be installed in compact, automated, or modular units.

Emflon® PFR membrane filter cartridge, 0.2 µm sterilizing grade, 10-inch length, double-o-ring (fluorocarbon elastomer) with bayonet lock and fin end - Emflon® PFR membrane filter cartridge, 0.2 µm sterilizing grade, 10-inch length, double-o-ring (fluorocarbon

Pall® AcroPrep 96 well filter plates, 350 μL 96 well filter plate, 0.45 μm, PTFE membrane, non-sterile, natural, 10/pk; Synonyms: 96 well filter plates; find -Z722235 MSDS, related peer-reviewed papers, technical documents, similar products & more at Sigma

PTFE membrane provides the ultimate in chemical compatibility for filtering harsh chemicals and HPLC mobile phases “Pall Laboratory products are designed for laboratory applications only. This product is not approved for use in medical, clinical, surgical or other patient applications.

These PTFE filter cartridges can withstand up to 1 bar (14.5 psi) differential pressure (forward direction) under steam sterilization conditions (125 C). This is combined with high flow rates and excellent dewetting characteristics resulting in very economical filtration

PTFE Membrane Disc Filters - TF 200, 0.2 µm, 142 mm (25/pkg) Product ID: 66145 Product ID 66145 Unit of Measure 1/PAC Min Order Qty 1 Diameter 142 mm Filter Media PTFE Minimum Bubble Point 1

Acro® 50 Vent Devices with PTFE Membrane - Discover more about the use of the Acro 50 devices in venting bioreactors, fermentation tanks, and carboys, sterile gas purging of culture vessels and filtering aggressive solvents