2019/12/15 · Fabrication of micropore-arrayed PTFE membrane Uniform micropore arrays in PTFE membrane was fabricated by ps laser drilling (Fig. 1b). The applied laser power was 20.0 W, repetition rate was 200 kHz, and scanning speed was 150 mm/s.

2021/7/1 · To quantitatively evaluate the microporous structure of ePTFE membranes, the average pore size and porosity as a function of the PTFE powder size is collected in Fig. 6. Firstly, an obvious enlargement of pore size from 0.65 μm of M-1-300 to 1.94 μm of M-4-300 could be observed in Fig. 6 A.

Product Description MS ® PTFE membrane media for filtration is made of PTFE (polytetrafluorothylene), and were drawn 2-demension. It is micro-pore film. The PTFE membrane was laminated with great variety of fabric and paper. Applied to extensive industries

2018/7/17 · The importance of inorganic membranes for gas separation and purification is analyzed. Although the cost of inorganic membranes is higher than that for polymeric membranes, they have higher permeance, selectivity and better resistance to higher pressure and temperature. The main materials used for porous inorganic membranes are alumina (Al2O3), silica (SiO2), zirconia (ZrO2), zeolite and

Only gaseous species can pass through the membrane and there is no convective flow through the pores of microporous hydrophobic membranes ( Aydin et al., 2018 ;Tugtas 2014 ).

Access efficient micropore pvdf membrane with reverse osmosis for purified drinking water at Alibaba.com. These micropore pvdf membrane are much advanced and ideal for commercial uses. Ready to Ship Trade Shows Personal Protective Equipment Services Sell

These micropore filter membrane are equipped with 12 to 24 filling heads and are loaded with unique technologies such as brackish water treatment, seawater desalination, portable water treatment. These micropore filter membrane are available in multiple power capacities and water purifying capacities ranging from 1000LPH -10000LPH.

Products/Services for Microporous Polyethylene Hollow Fiber Membranes. Chromatography Membranes - (18 companies) Chromatography membranes are designed for separation tasks in laboratory and industrial applications. They are built-in membrane systems such as plate and frame, spiral-wound module, hollow fibre module, and tube-in-shell module

membranes are cost effective compared to Teflon (polytetrafluoro ethylene, PTFE) and allow for a greater selection of membrane alternatives. The nylon substrates used here were surface treated for 30 minutes at a power rating of 100 W to achieve an optim al

2021/3/5 · The Main Classification of Microporous Filter Membrane. This system includes cellulose diacetate (CA), cellulose triacetate (CTA), nitrocellulose (CN), ethyl cellulose (EC), and mixed cellulose (CN-CA), etc. Among them, the standard and common filter membrane is the mixed cellulose membrane. Due to its good pore-forming performance, good

2019/12/15 · Fabrication of micropore-arrayed PTFE membrane Uniform micropore arrays in PTFE membrane was fabricated by ps laser drilling (Fig. 1b). The applied laser power was 20.0 W, repetition rate was 200 kHz, and scanning speed was 150 mm/s.

Only microporous PTFE membrane shows good gas absorption performance and stability without membrane wetting by MEA aqueous solutions for more than 6600 h due to its higher hydrophobicity [23].

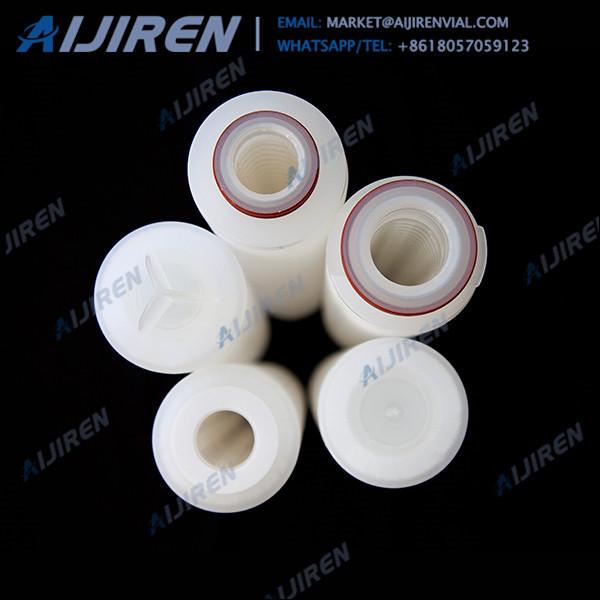

A porous form of PTFE (polytetrafluoroethylene), Zitex G exhibits the same chemical inertness, thermal stability and non-wetting characteristics of this outstanding fluoropolymer. Zitex G structures are able to handle virtually any corrosive fluid at temperatures as high as 500 o F (260 o C) and as low as the cryogenic range of -450 o F (-268 o C).

2018/7/17 · The importance of inorganic membranes for gas separation and purification is analyzed. Although the cost of inorganic membranes is higher than that for polymeric membranes, they have higher permeance, selectivity and better resistance to higher pressure and temperature. The main materials used for porous inorganic membranes are alumina (Al2O3), silica (SiO2), zirconia (ZrO2), zeolite and