Memtrex FE (MFE) filters with absolute rated PTFE membranes offer broad chemical compatibility with minimal extractables in a wide range of fluids and applications. The inherently hydrophobic PTFE membrane is ideally suited for the filtration of compressed air and other process gases.

Pall’s 96-well filter plates are available with various media and membranes that can be used across a range of laboratory life science and analytical applications. For multiplexing applications the combination of the AcroPrep plate’s smooth well wall design and the Supor® (polyethersulfone) membrane, with its highly consistent surface

Aug 07, 2018 · Polytetrafluoroethylene (PTFE) Membrane. Hydrophobic, highly inert, and durable, PTFE is a popular material with a wide operating temperature range and resistance to the damaging effect of many chemicals. When should you use it? DO USE: for filtering solvents and other aggressive chemicals, such as acetone and DMSO.

Sartofluor® contains PTFE membrane making it the most hydrophobic vent filter available. The inherent hydrophobicity of the PTFE membrane is unaffected by repeated autoclaving or steaming and guarantees sterile filtration of both dry and moist gases. Sartofluor ® filters show superior air flow rates throughout all sizes and formats. Applications

Downloads. Combines the excellent collection ability of a PTFE filter with a breathable reinforcing layer of non-woven fabric. Reduces absorbency and conductivity and also prevents post- collection dispersal of samples. Ensures superior release performance of the PM after collection (effective in micro-chemical analysis of composition).

MS® PTFE membrane offer excellent control over pore size, porosity, permeability and thickness.Designed to help deliver precision, accuracy and reliability.MS® PTFE Materials exemplify the critical design standards required in many challenging filtration and textile.

The new filter rated at 5 nm is constructed of ultra-high purity, polytetrafluoroethylene (PTFE) media and perfluoro alkoxy (PFA) hardware materials. PTFE is a high-performance material known for its chemical inertness making it ideal for more aggressive lithography solvents used in more advanced lithography processes including Negative Tone

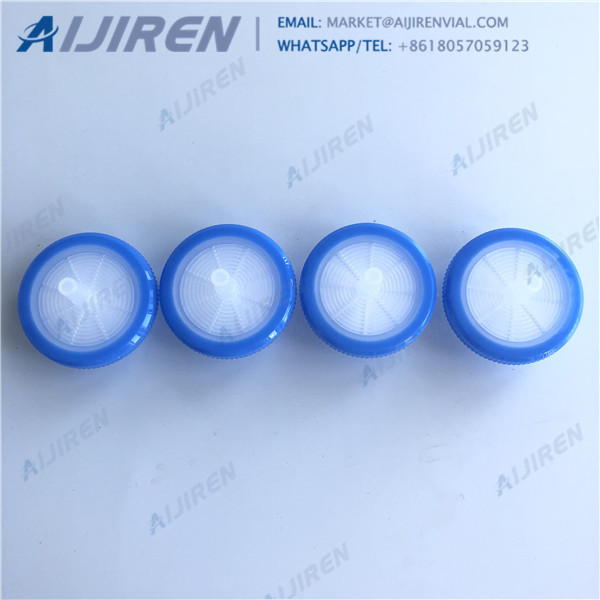

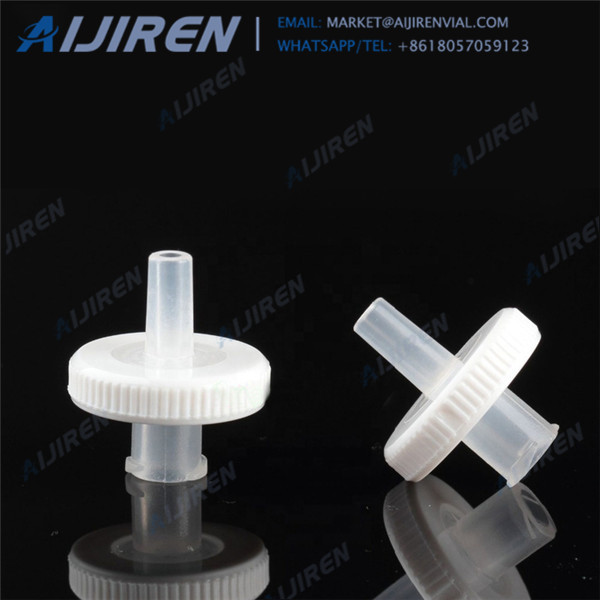

The wwPTFE membrane is ideal for sample preparation and solvent filtration. Extend column life up to 52x. Improve result quality with up to 24% less filter extractables and lower adsorption. Use one membrane filter type for all your sample preparation applications. Hydrophilic wwPTFE membrane also available in two LCMS-certified configurations.

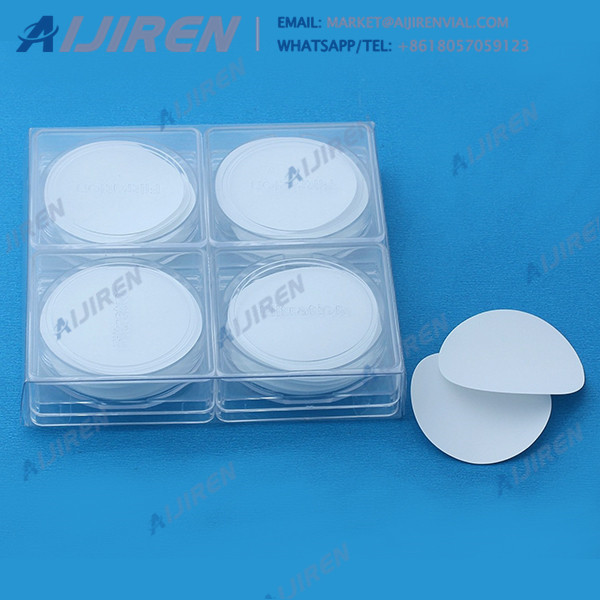

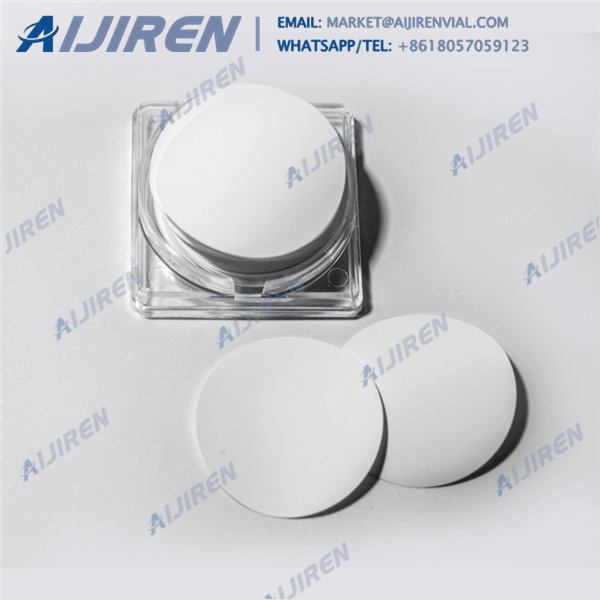

Laboratory filter membranes, also known as cut disc membranes, are used in conjunction with filter holders and other hardware in a variety of applications including prefiltration, solvent filtration, sample clarification, sterilizing filtration, air monitoring, particle collection and analysis, and other biological and environmental applications.

Membrane Solution’s advanced PTFE membranes (pore size:0.03-5μm) achieve the perfect combination of high flow rate,high retention and cost-effective. Material characteristics of MS®PTFE membrane include small diffusion flow and more pores in any given area. MS®PTFE membrane for filtration including hydrophobic membrane and hydrophilic

with aqueous and most organic solvents. They are excellent general filters for HPLC and organic solvent sample clean up. Specifications Membrane: HPLC certified PVDF Max. operanti g 100 °C temperature: Housing: Medical grade, virgin polypropylene Pre-filter: Binder free glass microfiber 1 µm (0.20 µm only) Porosities: 0.20 µm, 0.45 µm

PTFE membranes are a thin, unsupported, highly porous film that offers maximum chemical and pH resistance to a broad range of aqueous and organic solvents. This membrane exhibits high flow rates with minimal aqueous extractables(<0.3 wt%).

PTFE Membrane Disc Filters. Strong, Chemically Resistant Membranes for Air Monitoring and Sampling in Aggressive Environments. Low chemical background permits highly sensitive, interference-free determinations. Ensures accurate gravimetric determinations with low tare mass. Ideal for filtration of gas and/or organic solvents.

Choose a filter or membrane based on: 1) Chemical compatibility of the membrane and housing with your sample matrix. 2) Size and amount of particulates in the sample. 3) Potential interactions (binding) between the membrane and sample components. 4) Special considerations such as requirement for prefilter or inorganic ion certification.

If the filter membrane is not hydrophobic enough, moisture can accumulate and microorganisms may grow. A highly hydrophobic membrane can eliminate this danger along with any risk of water logging. Sartorius Sartofluor membranes are constructed of PTFE. It provides more than twice the hydrophobicity of polypropylene or PVDF.