The large-scale venting filters: more than 5 m-3/h-Retention rate: 0.2 μm Each membrane lot, liquid bacterial challenge test with the retention of -≥ 10⁷ Brevundimonas diminuta/cm² according to current ASTM F-838 guidelines-100% integrity tested before release--2

MilliporeSigma offers multiple membranes and device formats for vent filtration. Aervent® Filters Aervent 0.2 µm hydrophobic polytetrafluoroethylene (PTFE) filters provide sterility assurance, high flow rates and throughput and are used in pharmaceutical applications where it is critical to use a phobic filter with validated bacterial and viral retention capabilities.

Hydrophobic membrane materials for filter venting applications Download PDF Info Publication number US6811696B2 US6811696B2 US10/123,074 US12307402A US6811696B2 US 6811696 B2 US6811696 B2 US 6811696B2 US 12307402 A US12307402 A

.jpg)

In applications for air venting and gas delivery, hydrophobic membranes incorporated into finished devices may be required for equipment and healthcare worker protection as well as easing patient comfort and protection from environmental contamination.

2021/6/28 · PTFE Venting Membrane Market Size 2021 with CAGR of 5.4%, Top Growth Companies: GORE, Saint-Gobain, Donaldson, and, End-User, SWOT Analysis in Industry 2026 Published: June 28, 2021 at

Draining or filling of incubators, fermentation tanks, and other vessels requires a venting filter capable of preventing bacterial contamination. With an integral PTFE filter membrane, Whatman PolyVENT acts as an industrial air filter media for sterilization* of gases entering bioreactors such as fermentation tanks.

The CPM venting filter, type BA, allows for 100 percent sterile venting of storage tanks and containers in many industries, typically the water and dairy industries. Equipped with the patented, flexible Ecofilter ® element, consisting of filter membranes in between segmented stainless steel disks, the BA offers the highest filtration efficiency and security.

Tetratex membrane microporous films are naturally hydrophobic and can be used as permeable water barriers for venting or breather filters for gas sensors, electronics and more. Donaldson's proprietary oleophobic treatment process also makes filter media repel oils.

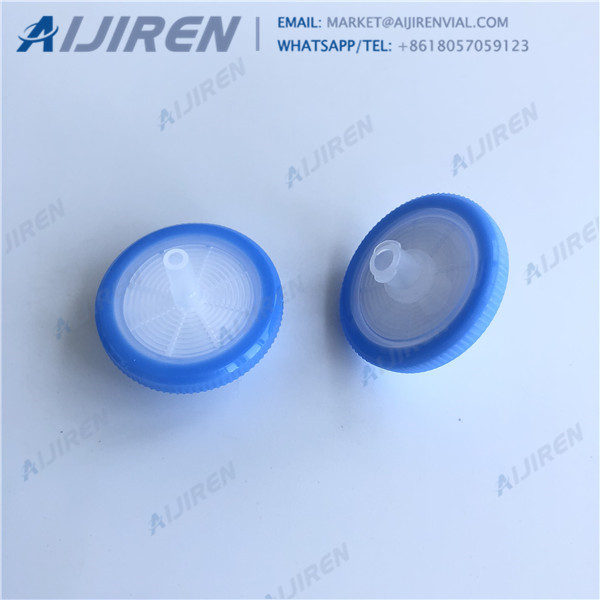

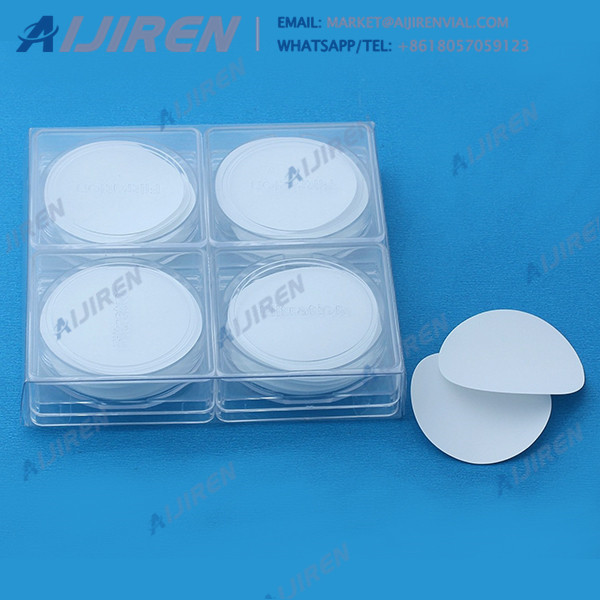

PTFE Syringe and Vent Filters. The PTFE syringe filter is available with or without a glass fiber prefilter. PTFE membranes are hydrophobic and are designed to filter most aggressive solvents whether they are acid or base samples. Our 50 mm PTFE syringe is excellent for venting applications or protecting a vacuum pump from liquid contamination.

Carboy Vent Filter, 0.2 Micron. Compact filter for venting and solvent filtration applications Useful for maintaining purified water stored in carboys Features a Teflon PTFE membrane Hydrophobic membrane permits sterile venting on a slow exhaust/liquid autoclave cycle of carboys up to

Venting membranes made from porous PTFE can be excellently welded on plastic parts, thermally or using ultrasonic technology. Welding enables a highly durable connection between the membrane and the component, even under harshest conditions.

2020/10/13 · Our new hydrophobic and oleophobic polyethersulfone membranes are designed for fast air filtration or sterile venting while preventing any liquid passage or condensate blockage. Their high performance and superior gamma stability make them a very efficient and powerful alternative to PTFE and will help you to increase your process and product security.

50 mm Filters with Superior Performancefor Demanding Applications. Reusable and autoclavable. PTFE membrane and polypropylene housing have broad chemical resistance. Large surface area provides greater throughput and high air flow rate. Available with a variety of inlet and outlet connectors.

PTFE membrane is a thin, highly porous film that behaves as an absolute retentive membrane. Their inherently hydrophobic nature make PTFE membranes ideal for applications such as filtering gases, aqueous aerosols, protecting vacuum pumps, or sterile venting fermentation tanks. PTFE is inert.

Specifically designed to separate components in batteries and fuel cells, our materials: Offer a wide variety of material and porous technologies – Assortment of materials including sintered particles, PTFE membrane, and porous fiber can be used in several types of batteries and fuel cells. Free of PFOA: Compliant with (EC) 1907/2006 REACH