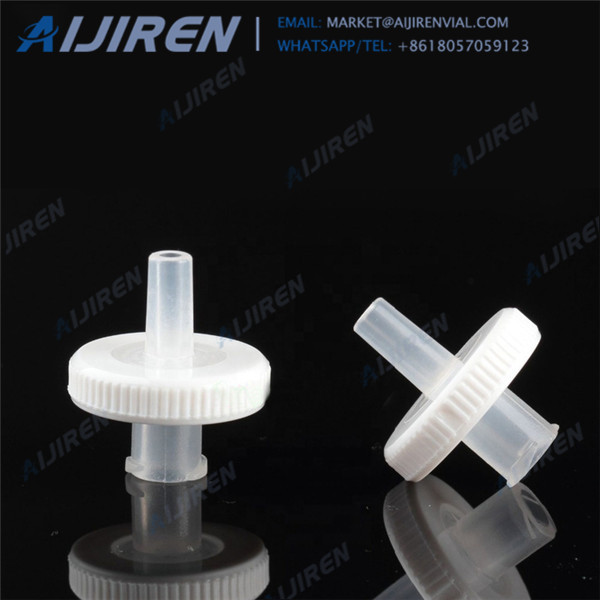

Hydrophilic PTFE syringe filters have broad chemical compatibility and high pH resistance and are optically clear when wet with water. They are versatile filters for use with aqueous and aggressive organic solvent-based solutions and are especially ideal for HPLC sample preparation.

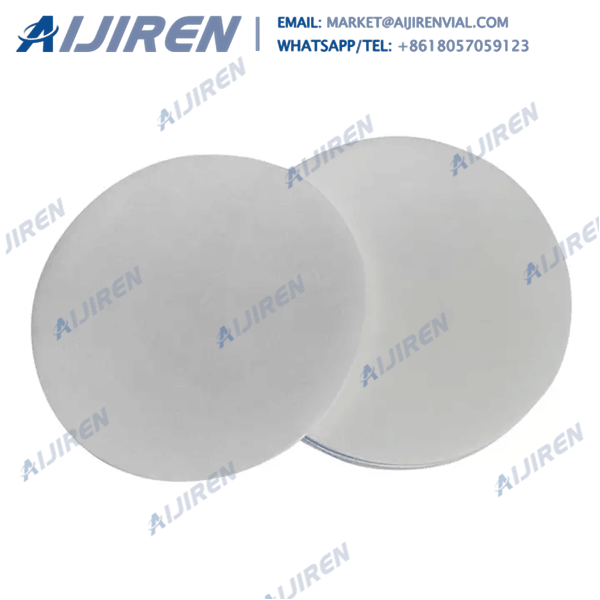

The hydrophobic PTFE membrane filters are made of polytetra-fluorethylene (PTFE) only and are therefore permanently hydrophobic. Unlike hydrophilic filter types, they are not wetted by air humidity. *Custom/bulk order quotes are provided within 72 hours of request.

Hydrophobic PTFE syringe filters have broad chemical compatibility and high pH resistance. These are versatile filters for use with aggressive organic solvent-based solutions and are especially ideal for HPLC sample preparation. The pure polypropylene housings are color-coded and available in smooth rim or gear rim formats.

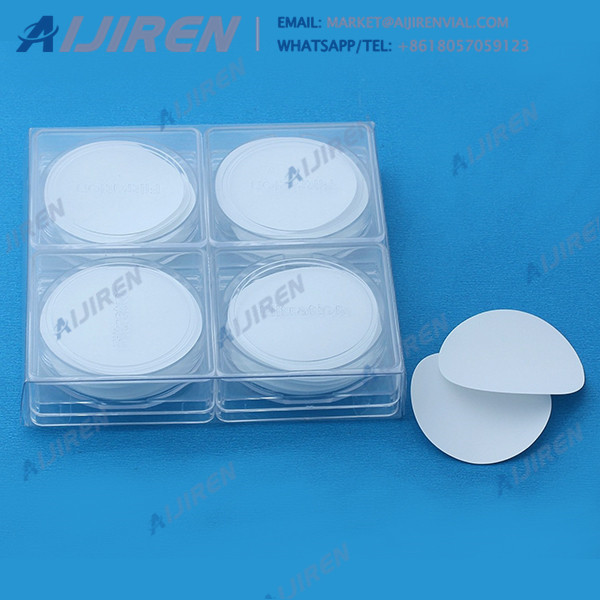

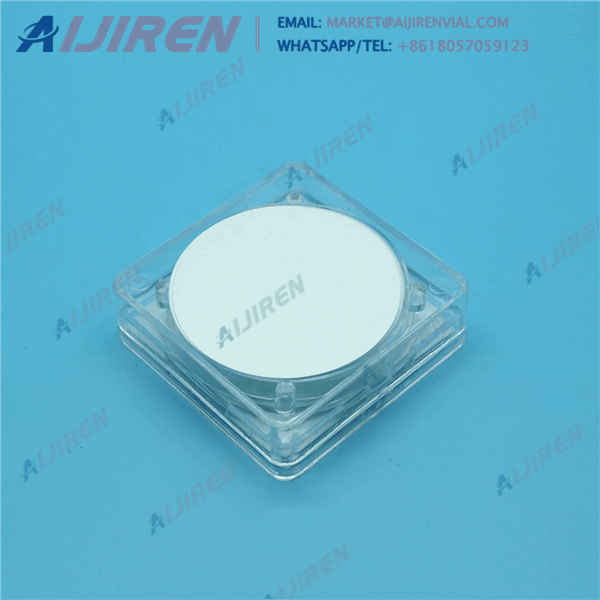

Hydrophobic membrane filter prevents moisture from passing through air vents and is resistant to almost all chemicals. Hydrophobic PTFE membrane filters have round disc types and roll types are both available for different applications. The operating temperature ranges from -120°C to 260°C. Inert to most aggressive solvents, including strong acids.

Intended Use: Retention or removal of biological contaminants. Instructions for Use: Sterilizing filtration of a liquid through a membrane with a 0.2 μm (or smaller) pore size effectively removes biological contaminants, including bacteria, mold and yeast. Storage Statement: Store in dry location.

Orange PTFE (Hydrophobic) Syringe Filters, 0.22 µm, 17 mm (100/pack) Hydrophobic PTFE syringe filters have broad chemical compatibility and high pH resistance. These are versatile filters for use with aggressive organic solvent-based solutions and are especially ideal for HPLC sample preparation. true false Part Number List Price Your Price

Use Aijiren Tech™ Choice™ PTFE Hydrophobic Syringe Filters for filtration of aggressive organic, highly basic or hot solutions and as transducer protectors. They can filter aqueous solutions after pre-wetting with an alcohol.

Hawach Hydrophobic PTFE membrane filters are top quality, high performance with the extremely low background, the full range of pore size and diameter.

Jul 9, 2019 · Various specifications of PTFE hydrophilic or hydrophobic are as follows: Pore size (the pore size is directly proportional to the flow rate, the larger the pore size, the faster the flow rate): 0.1/0.22/0.45/1.0/3.0/5.0/10 um ( Hydrophobic ), 0.22/0.45 um ( Hydrophilic ). Diameter (mm): 13, 25, 47, 90, 142, 293mm, etc.

The Pall Acro 50 is a disposable0.2 micron sterile vent filter and contains a Pall hydrophobic PTFE membrane, and is ideal for the sterile venting of small containers and as an in-line gas filter. The large effective filter area provides high flow rates, and filters can be autoclaved several times, ensuring low costs. Features

Aug 24, 2017 · Hydrophobic PTFE syringe filters 25mm Diameter 0.22μm Pore Size For Industrial Filtration by KS-Tek Biotechnology (PACK OF 25) FEATRURE: Hydrophobic PTFE membrane has wide chemical compatibility, excellent corrosion resistance, high rejection, high flow, and can be sterilized in various ways.

Description. The 0.2 µm hydrophobic Aervent® polytetrafluoroethylene (PTFE) membrane provides sterility assurance, high flow rates and throughput. The Aervent® membrane contributes to clean processes due its non-fiber releasing properties. Hydrophobic Aervent® cartridge filters provide high throughput with minimal differential pressure.

Catalogue Number. GVHP04700. Trade Name. Durapore ®. Description. Durapore® Membrane Filter, 0.22 µm. Background Information. Durapore® membranes provide high flow rates and throughput, low extractables and broad chemical compatibility. Hydrophlic Durapore® membrane binds far less protein than nylon, nitrocellulose, or PTFE membranes.

Hydrophilic PTFE membranes are typically used in filtering aqueous solutions, while hydrophobic PTFE membranes are typically used for filtering organic solvents and gases as well as particle monitoring.