Jul 22, 2021 · By contrast, for PTFE membranes, the hydrophobic mineral oil leads to a complete loss of water permeance within 2 hours, while hydrophilic alcohol and humic acid, and surface-active reagent SDS

Hydrophilic PTFE Membrane is a thin, unsupported porous film which is treated to be hydrophilic. This membrane exhibits high flow rates with minimal aqueous extractables. PTFE membrane is manufactured in a unique way where polytetrafluorethylene (PTFE) is expanded both uniaxially and biaxially.

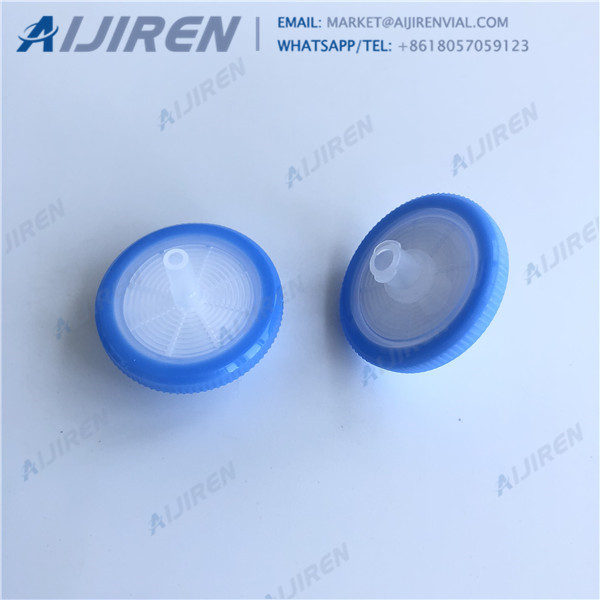

Feb 17, 2020 · The solution comes to be hydrophilic PTFE syringe filter from AirekaCells. Hydrophilic PTFE syringe filters offer a choice for aqueous samples that are diluted with harsh chemicals. These filters can handle high-temperature liquids , excellent flow rates, low protein binding, and are compatible with most bases, acids and organic solvents.

Meat rendering operations produce stick water waste which is rich in proteins, fats, and minerals. Membrane distillation (MD) may further recover water and valuable solids, but hydrophobic membranes are contaminated by the fats. Here, commercial hydrophobic polytetrafluorethylene (PTFE) membranes with a hydrophilic polyurethane surface layer (PU-PTFE) are used for the first time for direct

Advantec's line of unsupported, hydrophilic, pure PTFE membranes are ideally suited for use in HPLC separations and other applications involving mixtures of aqueous and organic solvents.

Jul 09, 2019 · Hydrophilic PTFE membrane filter is mainly used in: 1. Analysis of water samples to isolate RNA. 2. Clarifies filtered acid, alkali, and cryogenic liquids and diluted protein solutions. 3. Filtration of mixtures suitable for HPLC mobile phase and other water systems and organic solvents.

Titan3 PTFE (Hydrophilic) Syringe Filters 0.45 µm, 30 mm, 100 Pk. Diameter (Metric) 30 mm. Diameter (Metric) Membrane. 30 mm. Disposable. Yes. For Use With (Application) Sample Filtration: aggressive organic, highly basic, or hot solutions, transducer protectors; aqueous solutions after prewetting with an alcohol.

Fluoropore™ membranes provide broad chemical compatibility, high flow rates and consistency. (Please note that catalogue numbers containing "FHUP" are unlaminated, or produced without a backing.) Our Omnipore™ membrane is a hydrophilic PTFE membrane that is compatible with virually all solvents, acids, and alkaline solutions. Features

Cement. MS® ePTFE membrane filter bags have been installed in cement factories after resolving issues of higher filter cost and its maintenance, by using two technologies as follows: 1). surface filtration of ePTFE membrane, 2). a specially designed filter media with e-PTFE yarn/glass fiber composite to suit jet-pulse bag filters operating at high temperatures.

PTFE membranes with short-time, low-power air plasma and then deposited TiO2 on them (Fig. 2b).27 The resulting membrane surface showed high uniformity and was rendered hydrophilic with only 100 ALD cycles. ALD on PP membranes is similar to ALD on PTFE. Both plasma and nitric acid activation29 have been demonstrated to

PTFE Membrane for Dolomite's Membrane Chip Interface. For use with Dolomite’s Membrane Chip and Membrane Chip Interface for effective separation of organic and aqueous solutions, in-line filtration and liquid-liquid contracting, the hydrophilic PTFE membranes offer excellent chemical resistance with a pore size of 0.2 µm.

Sep 29, 2017 · PTFE membrane, which exhibited the typical fibrous structure of PTFE membranes [32]. The spaces The spaces between the fibres varied between 0.2 μ m and 1.0 μ m for both membranes, where the

Hydrophilic PTFE membrane is optimized for low drug and protein binding with excellent throughput in typical aqueous and solvent sample preparation. High sample recoveries and low extractables provide for optimum analysis by HPLC and LC/MS/MS. The membrane is suitable for applications including natural product screening, aqueous solubility

and minerals. Membrane distillation (MD) may further recover water and valuable solids, but hydrophobic membranes are contaminated by the fats. Here, commercial hydrophobic polytetrafluorethylene (PTFE) membranes with a hydrophilic polyurethane surface layer (PU-PTFE)

Hydrophilic and superhydrophilic surfaces and materials. Emil Chibowski. Jaroslaw Drelich. Konrad Terpilowski. Download PDF. Download Full PDF Package. This paper.