Ultradyne ® filters’ PTFE membrane delivers superior flow rates and long service life. The highly porous membrane is inherently hydrophobic and offers maximum chemical compatibility with minimal extractables in a wide range of fluids and applications. Support components are all-polypropylene. Design Features

Our PTFE membrane pleated filter cartridges normally classified into hydrophobic and hydrophilic two types according to its membrane material characteristics. From application aspects, the filter can also classified into ordinary industry PTFE filter, food and beverage PTFE filter and pharmaceutical PTFE filter.

3M™ Capillary Membrane MF-PP Series. Capillary and tubular membrane MF-PP Series. Inner diameters range from 50 µm to 5500 µm. These capillary membranes are widely used in the food and beverage industry, in waste water filtration and sterile filtration. MF-PP Series capillary membranes are also ideal for use in heavy-duty filtration

• Self-bonded hydrophilic media provides fixed pore structure, high containment of solid materials, no migration of media and no releasing of fibers • Contains no binders or adhesives, and each filter is pre-rinsed at the factory • Meets U.S. FDA, CFR Title 21 and 1935/2004/EC requirements for food and beverage

MS® PTFE membrane offer excellent control over pore size, porosity, permeability and thickness.Designed to help deliver precision, accuracy and reliability.MS® PTFE Materials exemplify the critical design standards required in many challenging filtration and textile.

STERYFLUS TSE Cartridges are specifically designed for sterile filtration of liquids in pharmaceutical, biotechnology, food & beverage applications. STERYFLUS TSE Cartridges are manufactured with PES membrane, polyester support media and polyester end-cap components in accordance with FDA, USP and EU/EC directives. Download PDF.

Once wetted, hydrophilic membranes will not allow the bulk flow of air or other gasses, unless See full list on sterlitech.com

Pall provides the Emflon® family of validated membrane cartridge filters to address the critical air/gas sterilizing filtration needs in the food and beverage industry. Table 1 provides an overview. All filters in the Pall Emflon family are comprised of hydrophobic PTFE membranes with polypropylene hardware.

Food Safety Compliance. Materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations, 21CFR. Materials used to produce filter media and hardware are deemed safe for use in contact with foodstuffs in accordance with EU Directives 2002/72/EC, 1935/2004, and/or 10/2011.

PTFE Hydrophobic Membrane. Gas Filtration and Analysis. Organic Solvent Filtration. Semiconductor Industry. Strong Corrosive Chemical Filtration. Hydrophilic PTFE Membrane. Pharmaceutical Industry. Food and Beverage Industry. Water Treatment and Chemical Industry. Filtration Strong Acid & Alkali Chemicals. Properties

Millipore® membranes have supported laboratory filtration in academic, pharmaceutical, and industrial sectors since the 1950s. We provide a range of membrane chemistries including MF-Millipore® mixed cellulose esters, Durapore® PVDF, Millipore Express® PLUS polyethersulfone, as well as hydrophilic and hydrophobic PTFE.

FOOD & BEVERAGE STERILE AIR/GAS FILTRATION P-SRF X – PTFE MEMBRANE Donaldson P-SRF X elements utilize PTFE membrane media in a stainless steel cage to provide superior filtration in extreme process conditions. It can withstand over 250 steam sterilization cycles and normal working temperatures up to 392°F.

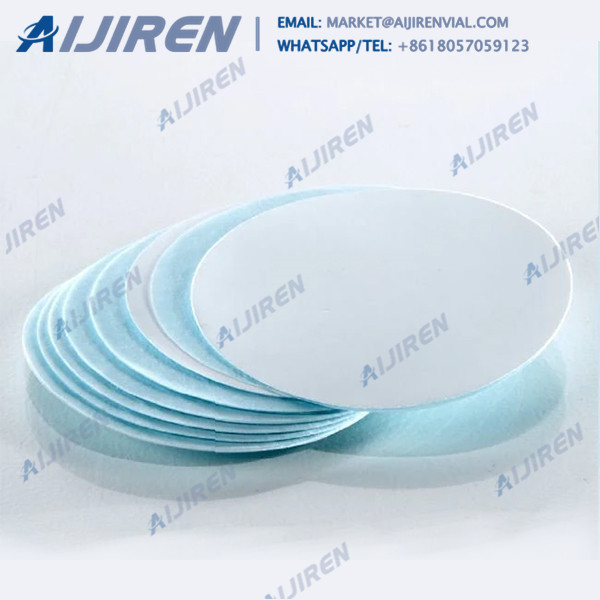

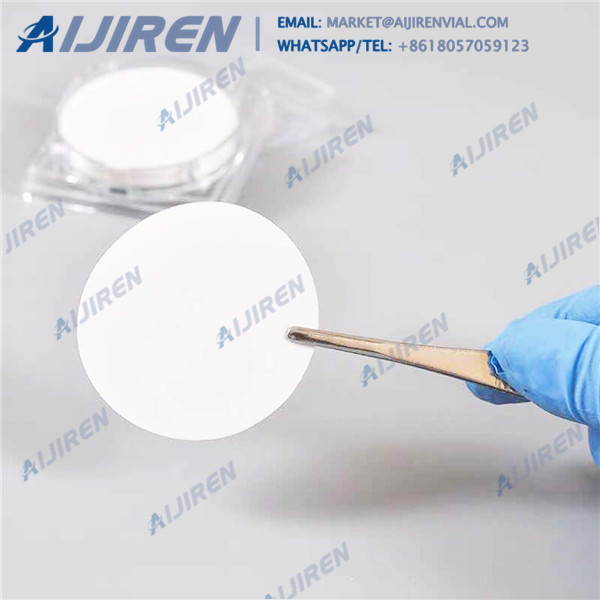

PTFE Membranes. PTFE membranes are available in hydrophilic, hydrophobic, unlaminated, and laminated options for a wide range of applications and temperatures. Unlaminated PTFE filters are chemically and biologically inert, stable up to 260°C (500°F), and naturally hydrophobic; they are very useful for aerosol sampling, air venting, and gas filtration, especially in environments also containing water vapor.

Hydrophilic PTFE Unsupported Membranes. Hydrophilic PTFE Membrane is a thin, unsupported porous film which is treated to be hydrophilic. This membrane exhibits high flow rates with minimal aqueous extractables. PTFE membrane is manufactured in a unique way where polytetrafluorethylene (PTFE) is expanded both uniaxially and biaxially.

PTFE Diaphragm Valve Uses and Applications. Diaphragm valves – also referred to as membrane valves – comprise a valve body along with at least two ports, a diaphragm, and a seat (saddle) upon which the valve is closed by the diaphragm.