PP, PTFE, PVDF, Nylon, PES Filtering Membrane with Various Diameter And Rating PP 0.45 Micron Capsule Filter for Printing Machine Small And Middle Size EDI Module for

Getting started Ptfe Membrane Filter Ptfe Membrane Filter - Factory, Suppliers, Manufacturers from China Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for Ptfe Membrane Filter, Silica Solid Phase Extraction Cartridges, Ptfe Membrane Filter, Protein Purification Resin Column,C8/SAX SPE.

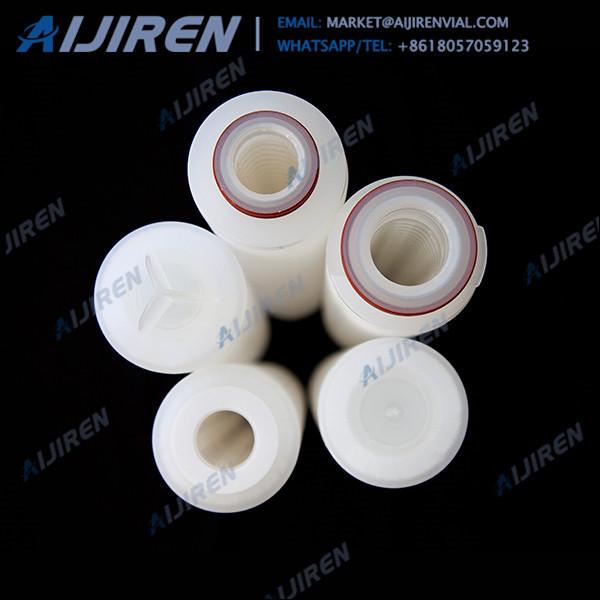

The Fluorocap®-XF encapsulated filter cartridge uses a superior asymmetric PTFE membrane which provides unmatched flow rates and on-stream life, and excellent chemical resistance for the most aggressive applications up to 180 C.

Automatic PTFE tapingPTFE taping speed: 4-10m/min. Diameter: 120-230mm. Equipped with automatic disconnection detection and automatic parking device. Equipped with stripping machine and film cutting collection device, high-power hot air device, high-power cutter motor and tungsten steel blade.

All Size of Sintered Filter Cartridge with Material PP, PA, PE and PTFE pp pleated filter cartridge deliver high effciency and consistent filtration of fluids in the food and beverage industry. They are constructed of pleated membrane filter media that provides removal of partical from 0.1 to 60 micron, the pore size is not affected by the

Polyester/PE Needle Punched Felt. Capable of manufacturing: 15,000 square meters per day (standard PE product) Width: ≤2.2m. Length: ≤100m. Type: Pure PE needle felt, PE blending needle felt , anti-static needle felt and water & oil proof PE needle felt. Finish-treatment: Calendering, Heat setting, Singeing.

PTFE Membrane Filter Cartridge For Aggressive Gas Filtration Filtration Membrane with Natural Strong Hydrophobicity, Ensure Absolute Sterilization Under Wet Or Dry Conditions, 100% Filter Gas Bacteriophage Filtration Biologically Inert, Chemically Resistant PTFE Media Uniform Pore Size Throughout Membrane For High Contaminant

Optional fibers: 316L and 304L stainless steel, nickel based high temperature alloys, or other metal fibers Outer diameters: up to 200mm Length: up to mm Features: higher permeability, good back flushing performance, long service life, excellent mechanical strength, stability, etc. Due to the surface filtration mechanism, the coarser support material renders the mechanical stability

The advanced expanded ptfe membrane offered by leading suppliers are made of sturdy metals, PVDF materials that assure long term durability and sustainability along with consistent performances. These expanded ptfe membrane are equipped with 12 to 24 filling heads and are loaded with unique technologies such as brackish water treatment, seawater desalination, portable water treatment.

PTFE Membrane Filter. We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for PTFE Membrane Filter, PTFE Bar, PTFE Tube Fitting, Teflon PTFE Sheet, If you are interested in any products, please feel free to contact us for further information or please send us email

More than 10 filter production lines, easy to realize mess production, to provide you with the best price. RAMPA® as a famous filtration & seperation products brand, for more than 10 years, we always puts clients' need at first, provide high quality filters and 24-hour service for our clients.

Hot Selling Cheap Pvdf Sea Microfiltration Ceramic Membrane Terracotta Water Filter Up to 5 years warranty US $20.00-$60.00 / Piece 1.0 Pieces (Min Order)

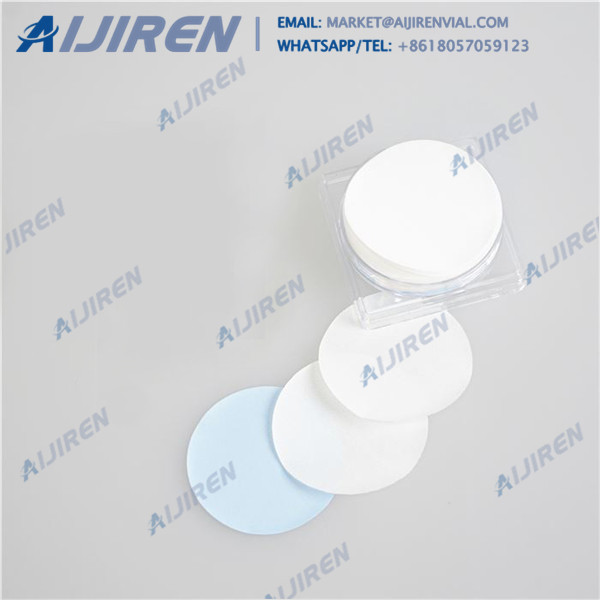

Filter Membranes. Produced by the precipitation or stretching of polymeric materials, membrane filters are commonly used in both industry and research. Properties of membrane filters vary widely with differences in composition, surface treatments, and pore size. Selecting the ideal filter requires an understanding of basic characteristics.

11/7/2013 · Process for Selecting a Filter 1. Determine the particle size to be retained or filtered. Membranes will retain all particles equal to, and larger than their designated pore size. 2. Assess the chemical compatibility of the membrane filter with the liquid or gas to be