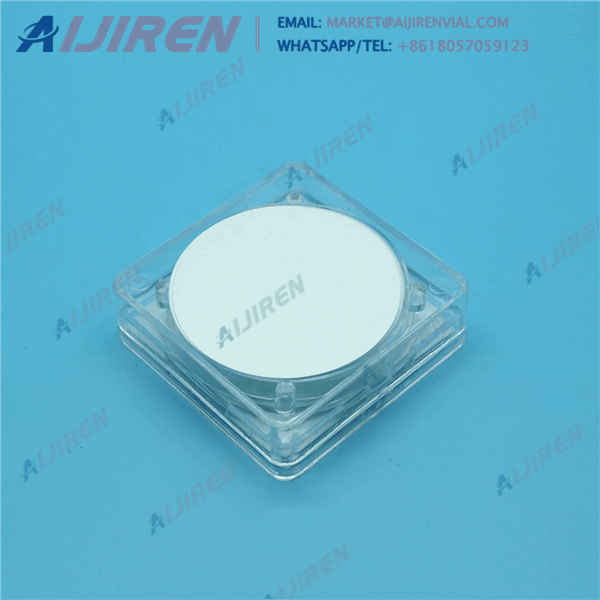

I.W. Tremont offers a line of high quality. membrane filters available in a variety of materials, diameters and pore sizes and suitable for a wide range. of applications including cell retention, In Vitro Diagnostics, particle collection, clarification and sterile filtration of. aqueous solutions, particulate analysis and microbiological analysis.

MS® PTFE Membrane Filters. MS® PTFE membrane filters are naturally hydrophobic, they are very useful for aerosol sampling, air venting, and gas filtration, especially in environments also containing water vapor. For filtering aqueous solutions, PTFE requires pre-wetting with alcohol to establish flow with reasonable pressure differentials.

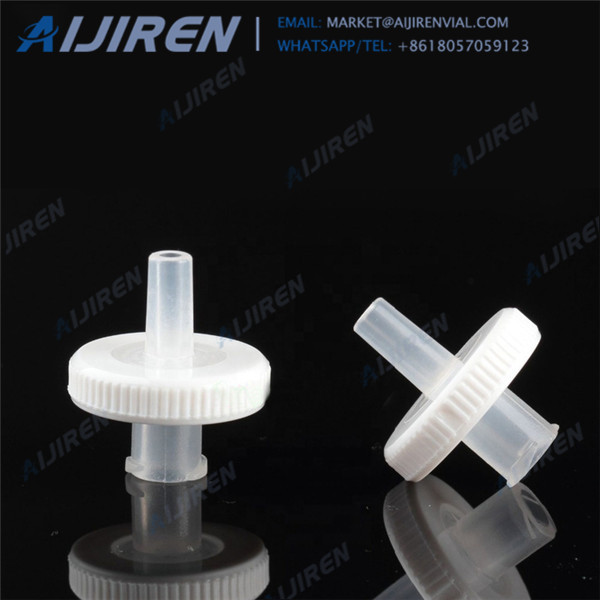

Acro 50 Vent Devices with PTFE Membrane. 50 mm Filters with Superior Performance for Demanding Applications. Reusable and autoclavable. PTFE membrane and polypropylene housing have broad chemical resistance. Large surface area provides greater throughput and high air flow rate. Available with a variety of inlet and outlet connectors.

applications, including solvent prefiltration for HPLC mobile phase, winterization and lipid removal cold filtration, filtration of media and buffers, and any sterilization or particle removal of mixtures incompatible with standard polystyrene filters.

ePTFE liquid filtration membrane is made of PTFE resin as a raw material, and is made into a polytetrafluoroethylene hydrophobic film by a special process and biaxial stretching, and then the original hydrophobic angle is changed to 34 ° C by special chemical and physical modification, thereby the membrane has the characteristics that the liquid can pass through a particle having a high

PVDF Membrane Filters. PVDF (polyvinylidene fluoride) is a hydrophobic, solvent resistant membrane that is known for it's high temperature resistance and high particulate removal efficiencies. PVDF is commonly used in the offshore oil and plumbing industries, and is suitable for Gas, Vapor, High-Temperature, Food, and Medicine Filtration.

These hydrophobic membranes provide ultimate chemical resistance and are temperature stable to 500 F (260 C). 2.0, 1.0, and 0.5-µm pore size PTFE filters are comprised of a tighter PTFE membrane laminated onto a PTFE support. These filters have two distinct sides — the tight, smooth PTFE membrane and the rough PTFE support.

High-purity PTFE membrane filter media provides superior chemical resistance for a broad range of industrial applications. With retention ratings as fine as 0.01μ (10 nanometers), consistent contaminant removal is achieved in aggressive fluids and organic solvents.

of gaseous or organic solvent-based samples. The modified membrane exhibits broad chemical resistance and unsurpassed temperature stability to address aggressive sample matrixes and extreme temperature situations. Low protein binding membrane The hydrophilic PTFE membranes are suitable for filtration of aqueous or highly aqueous/organic samples.

offers high-performance GD/X syringe filters with a multi-layer glass fiber prefilter for filtering larger volumes of harder-to-filter samples. Polyvinylidene difluoride (PVDF) membranes PVDF membranes are designed for high tensile strength, high solvent resistance, and low protein binding,

The enhanced PTFE membrane offers exceptionally high liquid flow rates at low pressure differentials making Fluorofil™ F100 cartridges ideally suited to solvent filtration. For solvent and aggressive chemical filtration applications, Fluorofil™ F100 cartridges offer a wide range of chemical compatibility with high thermal stability.

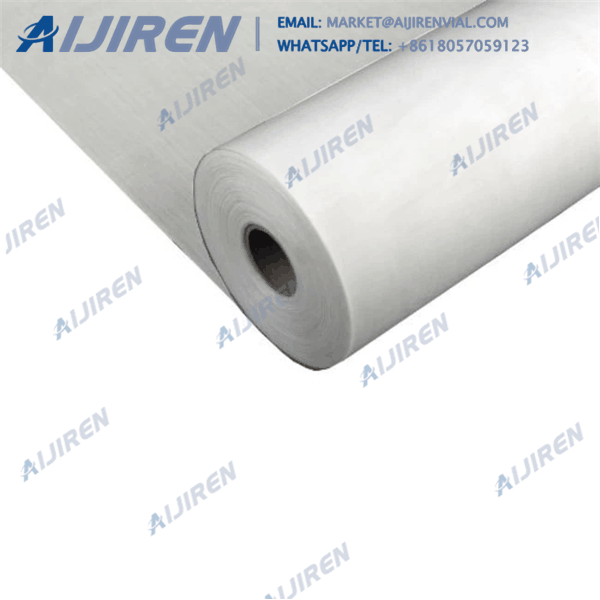

Membrane Solutions manufactures our own PTFE flat sheet membrane material. We use our high-quality PTFE material to create our membrane elements which are then installed into our modules for use in MBR systems and packages worldwide. In typical MBR processes, the assembled MBR systems or units are immersed directly into the biological tank or

MS ® hydrophilic PTFE membrane with excellent and permanent hydrophilicity, high porosity, best chemical compatibility and low protein adsorption,it is an ideal material for filtration of aqueous solutions and solvents. MS has developed PTFE membrane and PTFE surface modification technology for 7 years. Our membrane ,For your solutions.

larger volumes of harder-to-filter samples. Polyvinylidene difluoride (PVDF) membranes PVDF membranes are designed for high tensile strength, high solvent resistance, and low protein binding, making them suitable for biomedical filtration, sterilization filtration, and HPLC sample preparation.

Membrane Solution’s advanced PTFE membranes (pore size:0.03-5μm) achieve the perfect combination of high flow rate,high retention and cost-effective. Material characteristics of MS®PTFE membrane include small diffusion flow and more pores in any given area. MS®PTFE membrane for filtration including hydrophobic membrane and hydrophilic