Polytetrafluoroethylene (PTFE) is a fluoropolymer and is commonly known by its trade name, Teflon®. Unique properties of PTFE include nonreactivity, hydrophobicity, a low coefficient of friction, and good insulating properties. It is most commonly used as a nonstick coating for cookware. PTFE is also used in the manufacture of semiconductors

membrane. For example, PTFE membranes can be directly modified with Al2O3 through ALD without any pre-treatment (Fig. 2a).26 The underlying mechanisms of Al2O3 deposition are different for the inert PTFE surface compared to other membranes with polar

2013/9/27 · mineral-coated membrane enables an efficient and energy-saving separation for various oil/water such as PTFE-coated mesh 8, silicone-modified polyester textile 9 and polysiloxane

2019/7/22 · Most Common Dust Collectors for Mining and Minerals. Cartridge Collector Model 2DCP-4 and 2DCP-12. Baghouse Model 1309-PTHH-120-6. Another hazard in the mining and minerals industry is the large volume of dust being produced. This dust is hard and abrasive, and with large volumes, it results in filters wearing out rapidly.

KMX Technologies, LLC (“KMX”), a global market leader in membrane distillation, watertreatment, and critical mineral recovery, today announced the execution of an MOU withSumitomo Electric Industries, Ltd. to commence commercial production of KMX’s

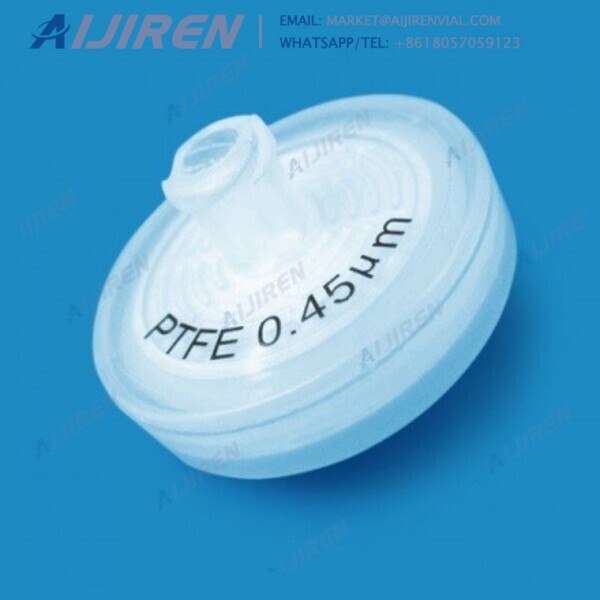

Membrane type Nylon PVDF PTFE PP PES CA RC Pore size Product code Product code Product code Product code Product code Product code Product code Quantity 0.2 μm 6870-2502 6872-2502 6874-2502 6878-2502 6876-2502 6880-2502 6887-2502 150/pack

.jpg)

China Pleated filter cartridge catalog of Industrial Micron PP/Pes/PTFE/Nylon Pleated Filter Cartridge for RO Water/Liquid/Wine Treatment, Hydrophilia Micro Cartridge Filter 0.45um PTFE Porous Membrane Filter for 10 20 Inch Mineral Water Filtration Plant provided

membrane, they did not wet the omniphobic membrane (Figure 2). The wetting of the PTFE membrane with mineral oil and ethanol is dynamic; the liquids initially beaded up upon contact with the membrane as drops with measurable contact angles but then

Chemical resistance ECTFE. ECTFE, also known as Halar®, is often chosen for applications requiring excellent barrier resistant properties. Products out of ECTFE have excellent mechanical, electrical and chemical properties. Note: The chemical resistance of each polymer is mainly determined by the chemical structure of the material and the

membranes used in vertical bone augmentation prior to implant insertion. In particular, the null hypothesis was that no difference would be found in the clinical and histological outcomes following bone regeneration obtained with d-PTFE membrane (d-PM) versus

Polysulfone Membranes. Polysulfone allows easy manufacturing of membranes, with reproducible properties and controllable size of pores down to 0.04 microns. Such membranes can be used in applications like hemodialysis, waste water recovery, food and beverage processing, and gas separation. These polymers are also used in the automotive and

Membranes 2020, 10, 89 3 of 28 Membranes 2020, 10, x FOR PEER REVIEW 3 of 30 Figure 1. Schematic representation of some membrane processes. Modified from [16]. 2.1. Pressure Driven Membrane processes Pressure driven membrane processes are by

2020/11/1 · Mineral deposits were uniformly distributed throughout the nanofiber surfaces; g and h, PTFE membrane without any mineral precipitation exhibited. Both are images of the surface designed to interact with the epithelial tissue; note the hexagonal surface texture, that according to the manufacturer helps to stabilize the membrane and the soft tissue flap.

ptfe manufacturer/supplier, China ptfe manufacturer & factory list, find qualified Chinese ptfe manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com. Business Type: Manufacturer/Factory , Trading