PTFE Membrane. PTFE Membrane Is Reusable Face Mask New Air Filter Material & Replace MeltBlown Non woven For N99, N95 Non Medical Mask, Disposable Face Mask. BEF≥99% & PFE≥95% Filter Efficiency Level. Also New Material For Medical Protective Clothing. If You Looking For Better or Best Air Filter Face Mask Material Alternative Solution About

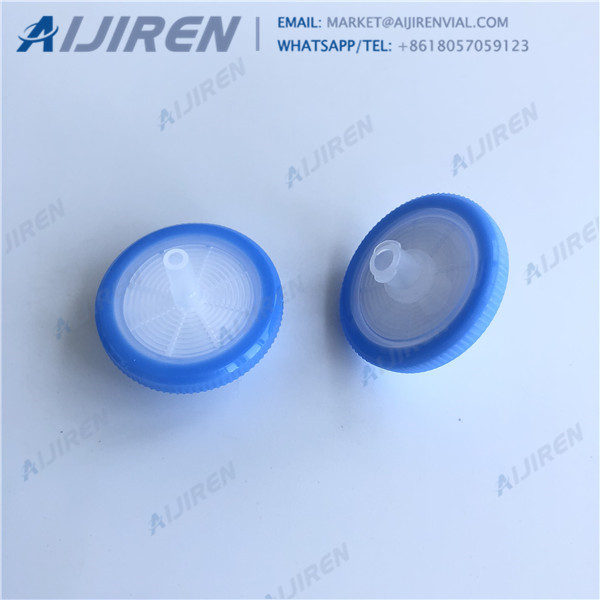

PTFE Membrane Filters - Membrane Filters | Sigma-Aldrich Get Quotation Pall Corporation Get Quotation Discounting 0.22um syringe filter for chemicals South Africa ptfe 0.2 micron filter for hospitals CONTACT US Tel:8618057059123 Address: NO.10 ...

The material of PTFE membrane for clothing is a new type of filter material formed by compounding a layer of PTFE membrane on the surface of the ordinary filter material. The main material of PTFE membrane is polypropylene, which is often interwoven with very fine fibers, and the average diameter of the fibers is about 2 μm.

.jpg)

Ostomy and Urine Bags DESCRIPTION MS®PTFE venting membranes can be used for Ostomy and Urine bags because of its perfect permeability,Which can prevent leakage, eliminate bag inflation and ensure the patients health and recovery. FEATURES

Lenzing PRoFILEN® PTFE Fibers in Medical Textile Applications Volker Biladt and Gallus Durz Lenzing Plastics GmbH & Co KG, Werkstraße 2, 4860 Lenzing, Austria Phone: +43 7672 701 3974, email: v.biladt@lenzing-plastics.com Abstract PTFE fibers are

2. Application of PTFE Micro Porous Membrane in Clothing Field. The diameter of PTFE micro porous membrane is between the molecular diameter of water vapor and the diameter of droplet. It can be waterproof and moisture permeable, and the cold air cannot penetrate the membrane, so it is very suitable for making clothing.

PTFE membrane is a thin, highly porous film that behaves as an absolute retentive membrane. Their inherently hydrophobic nature make PTFE membranes ideal for applications such as filtering gases, aqueous aerosols, protecting vacuum pumps, or sterile venting fermentation tanks. PTFE is inert.

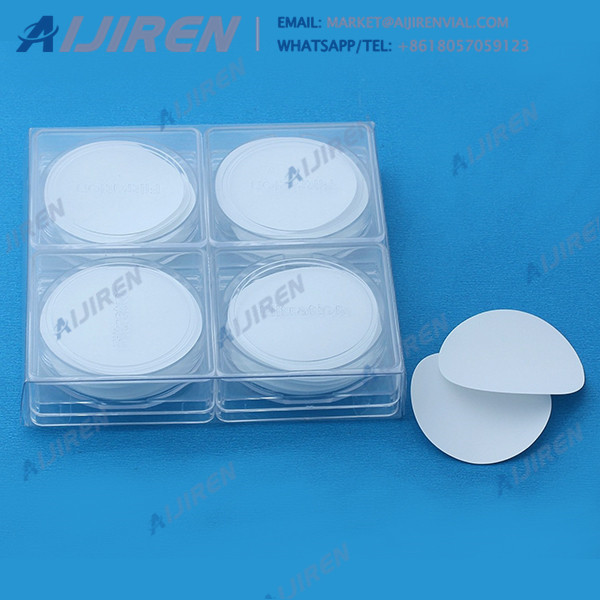

Our PTFE precut felts are offered in convenient non-sterile sheet sizes, which can readily be converted into finished medical devices. We can also offer Custom Configurations upon request. The PTFE precut felt are offered in soft and firm densities with weights of 800gsm to 1000gsm, respectively. Details Specification of our PTFE precut felt.

Medical mask also named surgical mask. Medical masks come in three primary styles, ear loops using a soft bandelastic, nose clip or with ties made from spunbond. Medical mask has high filtration efficiency than 99% and is ideal for hospital, dental, clean room

PTFE Membrane masks At present, masks have become a must-have item for human hands. With the increase of new cases of infection, the nationwide purchase of masks has become tense. At present, China's medical masks are mainly divided into three types

PTFE is also used to make gaskets because of its strength and heat resistance. It is also used as a thread seal tape for plumbing. PTFE also has good electric insulation properties and thus it is used to insulate cables and connector assemblies. This makes it ideal for

Aeos ePTFE products from Zeus feature microscopic pores in the material structure. Made by expanding PTFE under controlled conditions, these porous products are imparted with unique physical properties that make them ideal for use in medical devices

2018/3/1 · The biaxial stretching method used in preparation of PTFE membrane was originally developed by Stein and was used in porous PTFE membrane preparation for several years. As shown in Fig. 1(a), a lubricating agent is added so that the powder forms a paste that can then be extruded into sheet at a certain temperature.

Membrane solutions’ researchers can produce various PTFE membranes for your needs of pharmaceutical industry, utilizing: Tooling to produce various shapes and sizes Material options including: ePTFE membrane in a wide range of pore sizes, air flows, water and oil resistance, and particulate removal efficiencies

2019/9/10 · Conversely, as the internodal distance increases, porosity increases. Porous ePTFE can also be classified in volume densities. IPE has the capability of producing ePTFE in volumes densities ranging from 0.30 to 1.3 grams per cubic centimeter. Higher density ePTFE would be less porous and more rigid lower density would be more porous and flexible.