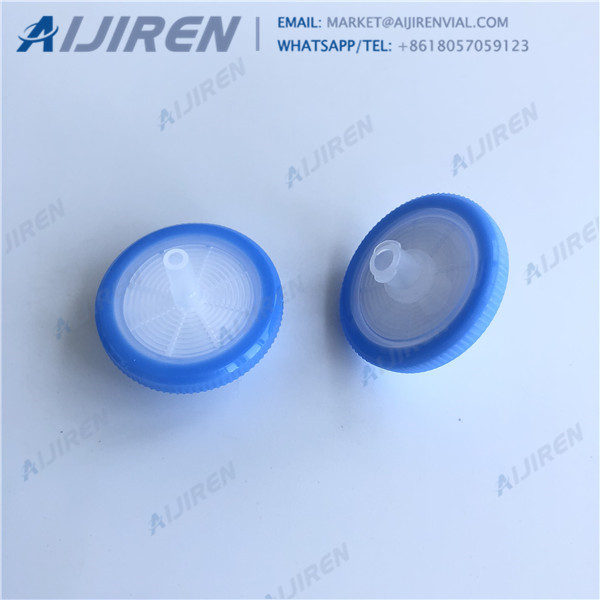

Corning ® syringe filters HPLC-certified non-sterile syringe filters are available with nylon, regenerated cellulose or polytetrafluorethylene (PTFE) membranes in

Corning® Gosselin Hydrophobic PTFE Filter, PP, PTFE Membrane Filling, 0.45 µm, Autoclavable, 10/Bag, 10/Case IMPORTANT UPDATE: Some items may be delayed in

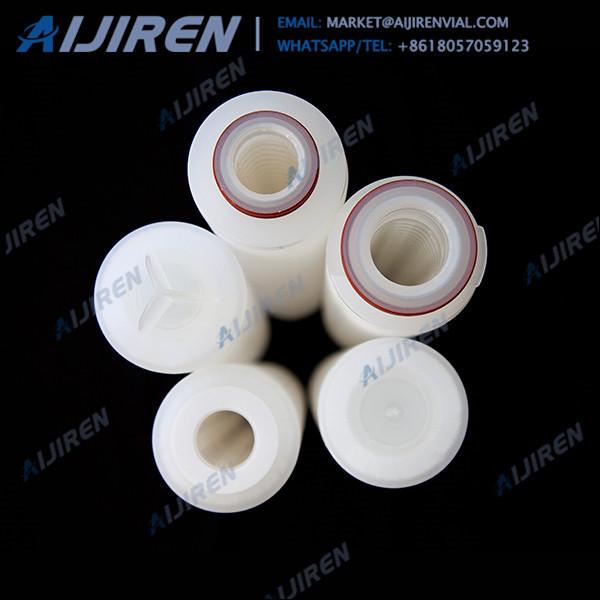

Corning® 430773 Sterile 500mL Vacuum Filter Unit with 0.2µm Nylon Membrane (Case of 12) This new vacuum filter/storage bottle system is designed for filtering and storing cell culture media, biological fluids, and other aqueous solutions.

Corning syringe filters are 100% integrity tested and are certified nonpyrogenic and noncytotoxic and are manufacturered in accordance with ISO 9002 standards. A variety of membranes are available to meet your needs. PES for low protein binding and faster flow rates; surfactant-free cellulose acetate (SFCA) for the lowest protein binding; PTFE for chemical resistance; and regenerated cellulose

Choosing a filter does not have to be complicated – Corning has simplified the process. Just follow these four easy steps: Step 1: Match your application with the best pore size. Step 2: Select the best membrane and housing material for your application. Step 3:

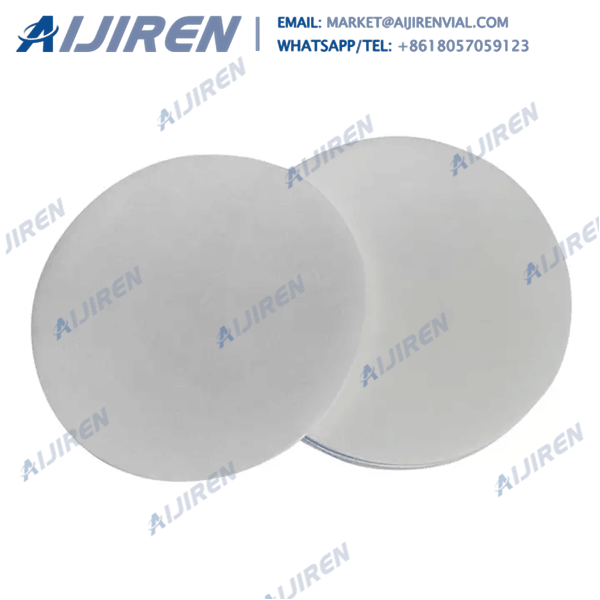

PTFE (Polytetrafluoroethylene) Membrane Filters. PTFE filters are the versatile choice for size-selective samplers. The material’s unique properties make it ideal for gravimetric, chemical, and/or microscopic analysis of sample particulate. PTFE filters are used for aerosol sampling, air venting and gas filtration.

Filter Membrane, Filter Media, Membrane manufacturer / supplier in China, offering Hydrophobic PTFE Filter Membrane for Air Filtration and Organic Solvent Filtration, Micro Polypropylene PP Membrane Filter Element for Water Filtration, PVDF Blotting Membrane

Corning, Membrane Solutions Membrane Filtration Products – Membrane Solutions. Corning & Process Technologies. Corning Incorporated is the world leader in specialty glass and ceramics. Drawing on more than 150 years of materials science and process engineering knowledge, Corning creates and makes keystone components that enable high-technology

These Corning® syringe filters have polypropylene copolymer housings, hose barb inlets and hose barb outlets. PTFE membranes provide the best chemical resistance. These naturally hydrophobic membranes can be used for venting applications or filtering gases. 100% integrity tested, sterile and nonpyrogenic and noncytotoxic.

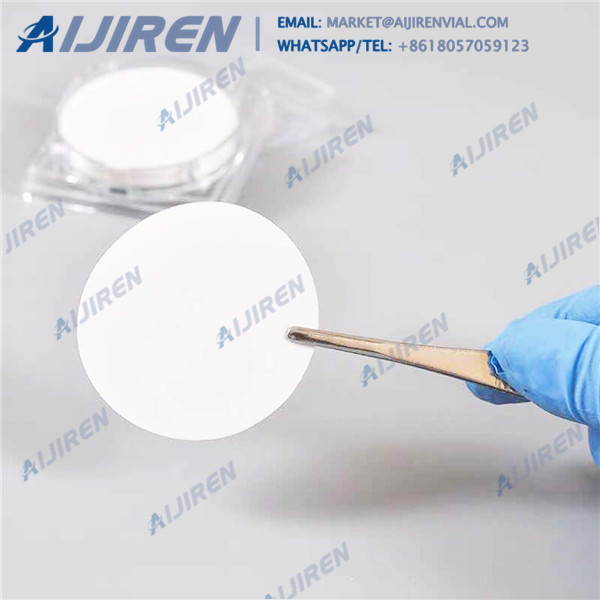

The collagen-coated PTFE membrane is fragile and requires careful handling during removal. A wetted cellulosic membrane filter should be placed in direct contact with the underside of the Transwell insert membrane before it is cut out with a scalpel. The wetted

Pore size and membrane type is printed on every syringe filter. Sterile filters are individually blister-wrapped in cases of 50, nonsterile in cases of 50. The 50mm PTFE syringe filter is supplied in case of 12. Compliance Manufactured to ISO 9002 and GMP

Membrane solutions offers a range of various PTFE hydrophobic membrane applied for air filtration . Material characteristics of the PTFE hydrophobic membrane include high flow rate and long service life at low operating pressures,so they are ideal for sterile filtration and venting of air/gases.

DESCRIPTION. Series of MS-AMYQ are exclusively designed for air monitoring. Membrane Solutions choose the safestpolytetrafluoroethylene (PTFE) as membrane material because of its remarkable features, such as: low chemical background, light quality and high chemical resistance.

These Costar® Spin-X® centrifuge tube filters have a 0.22 µm pore CA membrane-containing filter unit within a 500 µL capacity polypropylene microcentrifuge tube. Cellulose acetate (CA) membranes provide fast flow rates and low protein binding Ideal for removing