Filter Membrane, Filter Media, Membrane manufacturer / supplier in China, offering Hydrophobic PTFE Filter Membrane for Air Filtration and Organic Solvent Filtration, Micro Polypropylene PP Membrane Filter Element for Water Filtration, PVDF Blotting Membrane

Example:Filter needed for the apparatus fitting diameter size of 13mm Particle size (0.45um) , chemical compatibility (using Acid), and the membrane needed (hydrophilic) You will be able to find for example : PTFE Membrane filter with 0.45um pore diameter of 13mm

Choosing the Correct Syringe Filter. At Ossila, we offer five different membrane materials for our syringe filters: Hydrophobic PTFE (Polytetrafluoroethylene) Hydrophilic PTFE. Hydrophobic PVDF ( Polyvinylidene fluoride) PES (Polyethersulfone) Nylon. PTFE can be used with almost any solvent due to its low reactivity and low extractables.

PTFE Chemical Compatibility Chart: Polytetrafluoroethylene is very non-reactive and ideal for use with most chemicals. Review the chemical compatibility of Teflon® and PTFE with various chemicals, solvents, alcohols and other products in the cart below. Shop

Our Most Popular. Nylon Filters - Made with the same high quality nylon membranes as the AQ syringe filers. Pore Size: 0.22um or 0.45um or 1.5um PTFE Filters - Teflon membranes for use with non aqueous solvents. PVDF Filters - Membranes that will not

Description Teflo Membrane TF (PTFE) Membrane Filter Media/Support PTFE with PMP (polymethyl-pentene) support ring PTFE on a polypropylene support Typical Thickness 1 μm: 76 μm (3 mils) 2 μm: 46 μm (1.8 mils) 3 μm: 30.4 μm (1.2 mils) 0.2 μm: 139 μm (5

The Membrane and Process Development Product line at Sterlitech includes a wide range of commercially available polymeric flat sheet membranes, as well as ceramic membranes, bench-scale cross/tangential flow test cells, and filtration equipment. Sterlitech also offers Custom Designed Skid Mount Membrane Filtration Systems.

PES Membrane Filter Cat.No Description Pack(qty/case) MFMCE037022 MCE Membrane Filter Pore size0.22um, Diameter 37mm 200 MFMCE293045 Pore size0.45um, Diameter293mm 25 MS® Mixed Cellulose Esters(MCE) Membrane Filter Membrane Filter

Millex-FA Syringe Filter Unit, 1.0 µm, hydrophobic PTFE, 50 mm, HB-HB. Product Number. Product Description. SDS. SLFA050. A 50 mm diameter non-sterile syringe filter with a 1 µm filter pore size hydrophobic PTFE membrane. The 1 micron filter comes in a pack of 10.

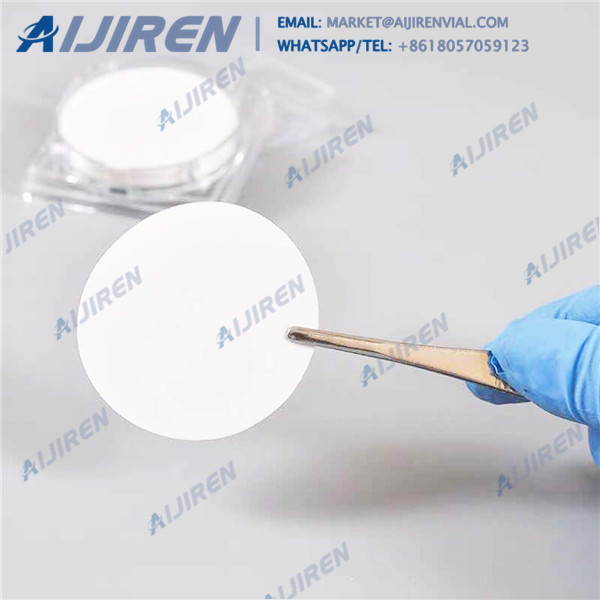

Laboratory filter membranes, also known as cut disc membranes, are used in conjunction with filter holders and other hardware in a variety of applications including prefiltration, solvent filtration, sample clarification, sterilizing filtration, air monitoring, particle collection and analysis, and other biological and environmental applications.

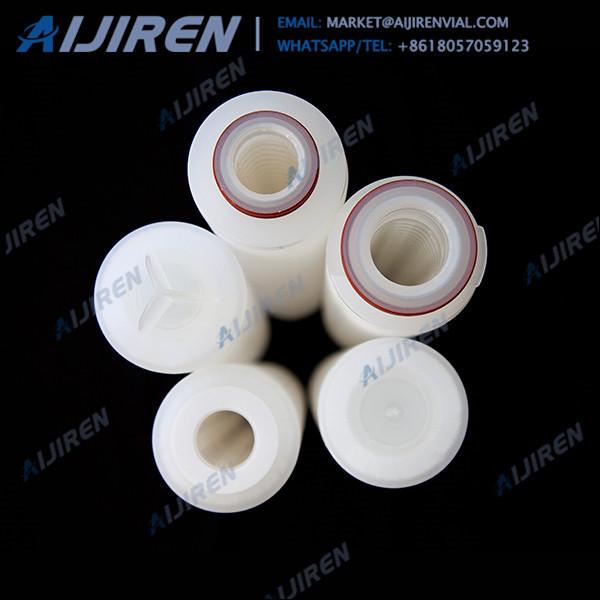

Removal rating: 0.1 µm - 0.45 µm PtSEP Series Pleated Filter Cartridge has the pleated filtration layer composed of PTFE membrane and distribution layer. Its filtration ratings ranges from 0.1μm to 0.45μm. Removal rating: 0.05 µm - 1 µm Description Orders

Description. Pall Emflon® FM filter cartridges are designed for cost-effective clarification of solvents used in the manufacture of antibiotics and other active pharmaceutical ingredients (APIs). These pharmaceutical grade filters contain a proprietary PTFE membrane and are compatible with a broad range of chemicals.

Nylon membrane has high mechanical strength, chemical stability, can be tolerated by most organic solvents and the majority of water solution filter characteristics.It more often applied to the common organic solvent HPLC mobile phase filtering. PTFE membrane

PTFE membrane filters are ideal for gas filtration. These membranes are permanently hydrophobic by their composition, thus the pressure for filtration of aqueous solutions has to be higher than the breakthrough pressure. Johnson Test Papers’ PTFE membranes can be used at temperature up to 130 °C. PTFE membrane filters are available in both

2018/8/7 · Membrane-sample Compatibility It’s easy to overlook membrane compatibility when picking out your filter or device for your sample filtration. Good membrane-sample compatibility supports efficient filtration and minimizes resistance, while poor compatibility might result in backpressure, ineffective filtration, or even chemical attack of your membrane, leading to contamination of your filtrate.