SupaPore TL Microfiltration cartridges have been specifically designed for use in corrosive gases and liquid processing applications. A naturally highly hydrophobic PTFE membrane and Halar ECTFE structure makes this the cartridge of choice where high resistance to aggressive fluids is required.

1.Bartee BK, Carr JA. Evaluation of a high-density polytetrafluoroethylene (n-PTFE) membrane as a barrier material to facilitate guided bone regeneration in the rat man-dible. J Oral Implantol 1995;21:88-95. 2.Bartee BK. The use of high-density

Gas diffusion electrodes (GDE) are electrodes with a conjunction of a solid, liquid and gaseous interface, and an electrical conducting catalyst supporting an electrochemical reaction between the liquid and the gaseous phase. Principle GDEs are used in fuel cells, where oxygen and hydrogen react at the gas diffusion electrodes, to form water, while converting the chemical bond energy into

5/9/2016 · For the ETFE membrane, 11 specimens were designed with different colors, printing silver dot ratios, and layer numbers (Fig. 5 and Table 1).For the PTFE membrane, the color was brown after manufacturing, and then turned into white after 3 months under

A PTFE membrane for the in situ extraction of dissolved gases in natural Aijiren Technology: Theory and applications

Area of use PTFE is popularly used as a non-stick coating for pans and many modern items of cookware. PTFE is often used in containers and pipes for handling reactive and corrosive chemicals. This is because it has non-reactive properties. Another practical

16/7/2020 · This study reports alkaline membrane fuel cells that can be operated continuously for over 1000 h at back pressurization of the reacting gasses is a common technique that is used to enhance ...

PTFE is used as an inner coating material in non-stick cookware. This unique polymer coating prevents food from sticking in the pans during the cooking process. Such cookware is also easy to wash. At normal cooking temperatures, PTFE-coated cookware releases various gases and chemicals that present mild to severe toxicity.

Since 1958, Gore has developed products that improve lives. At the center of these solutions is polytetrafluoroethylene (PTFE), a polymer with exceptional properties like high tensile strength, a low dielectric constant, UV resistance and many more. In 1969, the possibilities for PTFE expanded with Bob Gore’s discovery of expanded PTFE, or ePTFE.

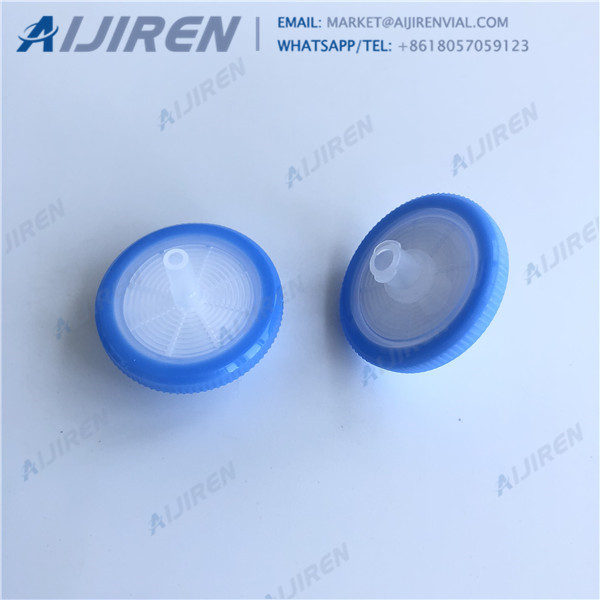

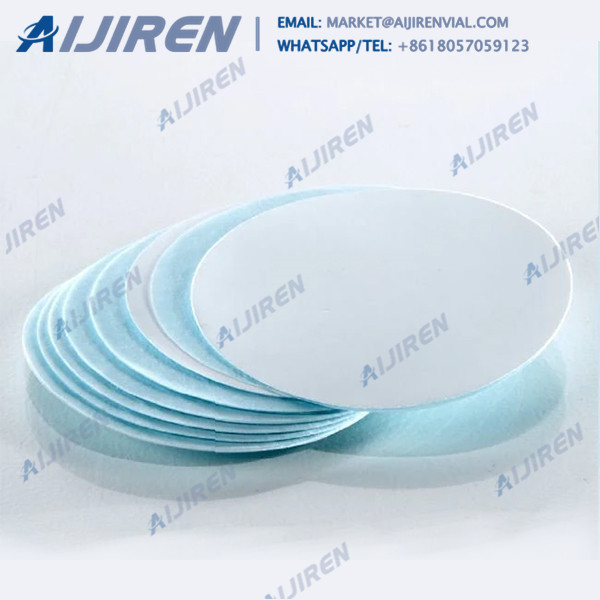

2/7/2021 · Commonly used filter membranes: MCE (Mixed Cellulose), PES (polyethersulfone), Nylon (nylon), PVDF (Polyvinylidene Fluoride) and PTFE (Polytetrafluoroethylene). Skip to

The use of membrane contactor in industrial processes is wide, and lately it started to be used in CO 2 capture process mainly for gas purification or to reduce the emission. Use of the membrane contactor provides high contact surface area so the size of the absorber unit significantly decreases, which is an important factor for commercialization. The research has been caried out regarding the

PTFE membrane. Overall, PET is the best insert membrane material for use in fluorescence-imaging applications. PC, PET, and collagen-coated PTFE inserts are all suitable for barrier assays Another common application for cell culture inserts is the barriertop of

High flow PTFE membrane Removal of liquids, aerosols and particulate Stainless Steel Membrane Housings HFM100 7 Flow Rate vs Pressure Drop High Flow Membrane P r e s s u r e D r o p [P S i] 6.50 5.80 5.00 4.50 3.62 2.90 2.17 1.45 0.75 0.00 0 10 20 30

A step by step guide for a type 3 defect: Perforation of the cortical, autogenous bone as a first layer, and xenograft on top mixed with autogenous bone. A e-PTFE membrane is finally placed. Horizontal and vertical bone regeneration using a e-PTFE membrane. This case the fixture was placed simultaneously to the augmentation.