(ideal for use with DMSO-containing solutions), or surfactant-free cellulose acetate membranes in either polypropylene or acrylic copolymer housings. The larger 50 mm diameter disc filter has a PTFE membrane and polypropylene housing with hose

2018/2/2 · Disadvantages of PTFE (Gore-Tex) Not as flexible as PU films – stiff and hard to move in sometimes Can be substantially heavier than an item that uses HyVent Because Gore-Tex is a membrane, not a coating, any place that cannot have a membrane applied is

Polytetrafluoroethylene, or PTFE, is a versatile polymer that has been in use since 1938. There are many uses of PTFE in industrial and consumer applications. The two main components of PTFE are carbon and fluorine. This combination gives PTFE a high

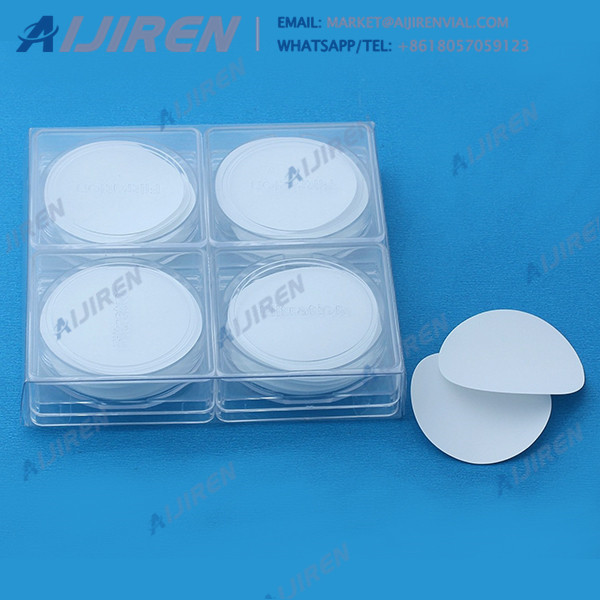

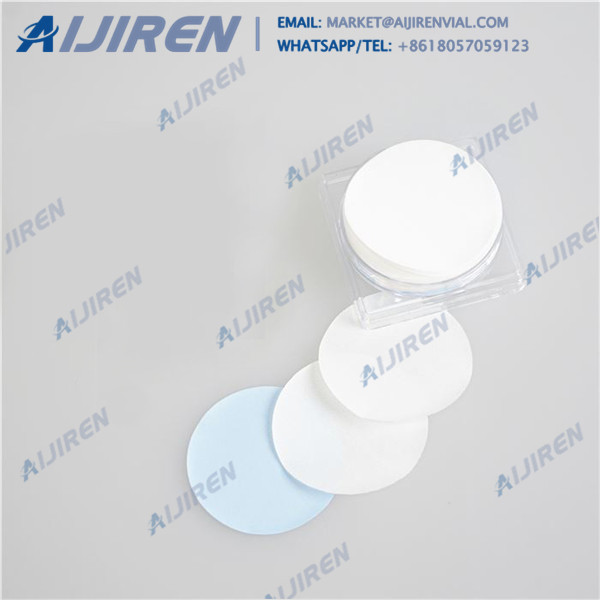

Membrane Filters Diameter 47 mm Pore Size 0.22 μm or 0.45 μm for Laboratory Filtration Membrane by Allpure Biotechnology [100 piece per box] (47mm-0.22μm, Hydrophilic PTFE) £38.95 - £45.95 #28

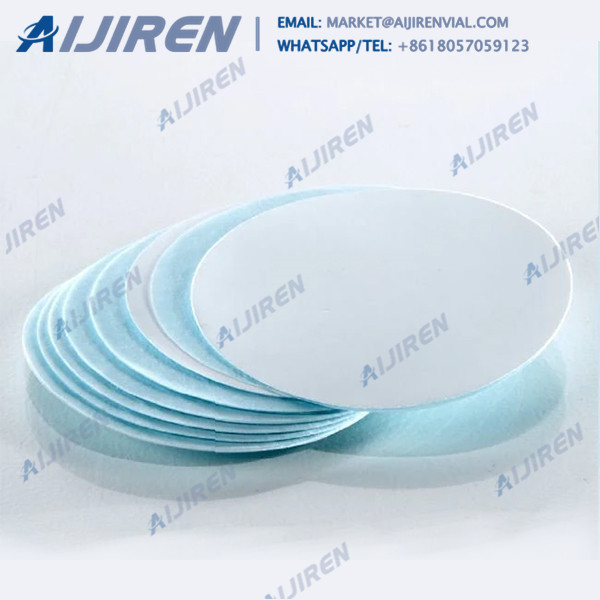

Filter Membranes. Produced by the precipitation or stretching of polymeric materials, membrane filters are commonly used in both industry and research. Properties of membrane filters vary widely with differences in composition, surface treatments, and pore size. Selecting the ideal filter requires an understanding of basic characteristics.

2018/11/27 · Top advantages of using PTFE and Teflon Coating Services. Applications include nuts, bolts and fasteners, cable supports, panels for conveyors in the Food Industry, Aerospace components and more. There are a number of advantages of using Teflon coatings.

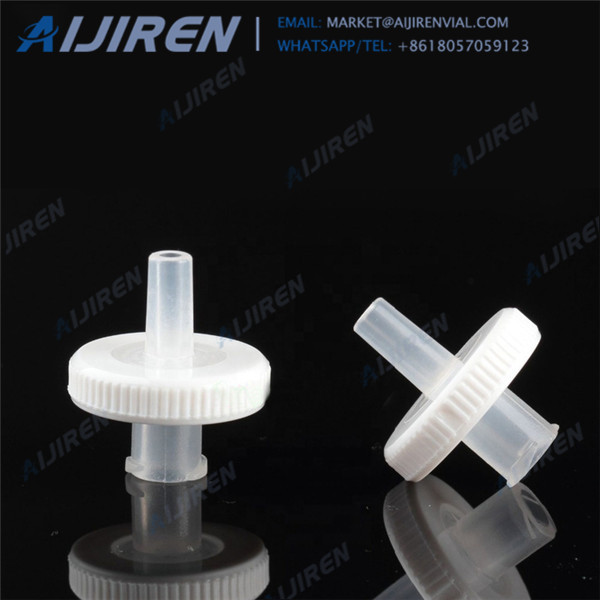

Buy Biomed Scientific Syringe Filters PTFE Membrane 25mm Diameter 0.22um Pore Size Non Sterile Pack of 10: Industrial & Scientific - Amazon.com FREE DELIVERY possible on eligible purchases Amazon Music Stream millions of songs Amazon Advertising

The most common emulsification membranes are SPG membrane, polymeric membranes, and microsieve membranes. Nanoemulsions comprising soybean oil or MCT oil dispersed in aqueous solutions of SDS or Tween 20 can be prepared by direct ME using SPG membranes with a maximum pore size of 0.2 μm and the ratio of the median drop size to the mean pore size ranges from 2.8:1 to 8.2:1.

Four types of Membrane Fouling. There are four categories of membrane fouling. They are (a) inorganic fouling/scaling, (b) particle/colloids fouling, (c) microbial fouling, and (d) organic fouling. A brief description on the nature of fouling, relevant water quality as indicators, and control measures are summarized below for each type of

Polytetrafluoroethylene or PTFE is the commonly used versatile, high-performance fluoropolymer made up for carbon and fluorine atoms. One of the common applications of this polymer is non-stick coating in kitchen cookware (pans, baking trays etc.), hence, you can easily find this in your kitchen. PTFE is a linear polymer of tetrafluoroethylene

ABOUTTORAY MEMBRANE. that produce clean water and recover valuable resources. Explore our line-up of advanced RO, NF, UF, MBR and antiscalant membrane technologies. Design efficient membrane treatment systems using Toray’s projection and normalization software tools.

PTFE (Polytetrafluoroethylene) Membrane Filters. PTFE filters are the versatile choice for size-selective samplers. The material’s unique properties make it ideal for gravimetric, chemical, and/or microscopic analysis of sample particulate. PTFE filters are used for aerosol sampling, air venting and gas filtration.

Bacterial Retention Validation Using Minimum Bubble Point Membranes Membranes used for bacterial retention validation range between 50 and 54 psig (3450 and 3725 mbarg). In this sense, 50 to 54 psig (3450 to 3725 mbarg) can be said to be truly representative of low-end bubble point values from typical manufacturing, as this represents 13% of our membrane production.

PTFE, FEP, and Nylon tubing materials feature mechanical properties ideally suited to consistently perform in the harshest conditions. Though there are several distinctions among the materials, they do share some similar properties and are relatively chemically inert. The material can be fabricated to any specification or form, too.

5- Membrane Materials. Organic membranes. Typical materials used in formulating organic membranes are: - polyethylene (PE) - polytetrafluoroethylene (PTFE) - polypropylene (PP) - cellulose acetate (CA), Polyacrylonitrile (PAN)