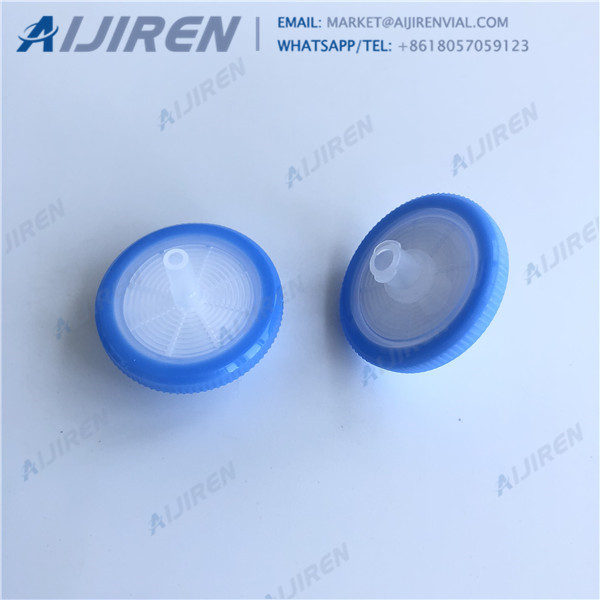

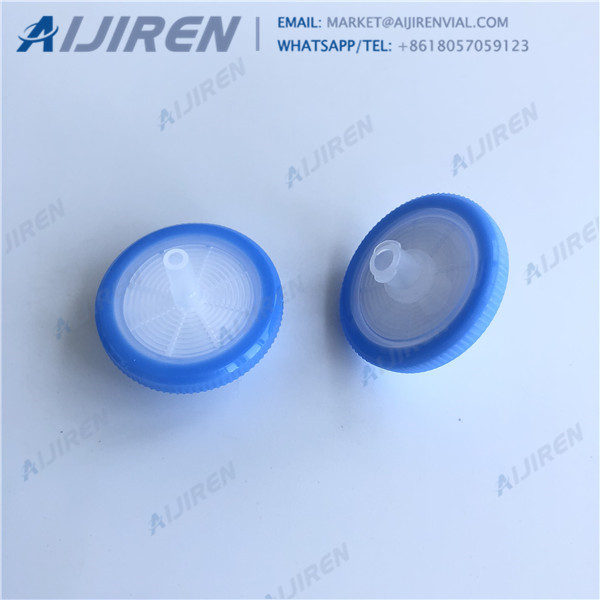

Available in sizes and membrane types to meet any application need, Aijiren Tech™ Titan3™ PTFE Hydrophobic Syringe Filters provide cleaner sample extracts by removing interfering materials and fine particles. These filters are used for filtration of aggressive organic, highly basic or hot solutions and as transducer protectors.

Feb 19, 2019 · Hydrophobic (25 mm diameter×80 μm thickness) PTFE filter membranes of 0.45 μm pore size by Sartorius were used. Mb from human heart, BSA and catalase from bovine liver were obtained from Sigma-Aldrich and used as received. Aβ 42 oligomers were prepared as previously described. 63. AgNWs Synthesis

Hydrophobic PTFE Membrane Filter Cartridge Type B---Round Flange Series Model Name: B-PET-386-35140F4 Size: Φ386-Φ350*Φ240*1400MM Media Type: PET-F4/260 Filter Media: Hydrophobic PTFE Membrane Filter Cartridge Filtration Area: 23m2 Metal treatment: Powder spray coating metal/stainless steel mes; Related tags : dust collector, dust filter

This should be taken into consideration when deciding which syringe filter material to use. For example, some syringe filter membrane materials are high protein binding, while some are low protein binding. Others are hydrophobic or repel water, meaning water will not flow through them, while some are hydrophilic, or the opposite of hydrophobic

In the health care industry, such filters must be sterilized before use. Polytetrafluoroethylene (PTFE) has been the most common material in filters for gas venting. PTFE is chemically and biologically inert, has high stability, and is hydrophobic. PTFE filters therefore allow gases to be selectively vented while being impervious to liquid water.

Automated food microbiology: potential for the hydrophobic grid-membrane filter. (2/410) Bacterial counts obtained on hydrophobic grid-membrane filters were comparable to conventional plate counts for Pseudomonas aeruginosa, Escherichia coli, and Staphylococcus aureus in homogenates from a range of foods.

The intention was to use the tight pore structure of the sponge layer to prevent the brackish water from intruding into the membranes and low tortuosity of the macro-void layer to facilitate water-vapor transport through the membranes. The PTFE membrane has a rather symmetric pore structure as shown in Figure 3. The uni-axial tension applied

Universal Hydrophilic Syringe Filters: Millex® Hydrophilic PTFE. Polytetrafluoroethylene (PTFE) is widely used in membrane filters due to its high chemical resistance and low protein binding. However, the native hydrophobicity of unmodified PTFE restricts its use to the filtration of organic solvents and solutions.

Foxx Life Science Carboy Vent Filters are used for hydrophobic venting and solvent filtration applications. The PTFE filter membrane is ideal for maintaining purified water stored in carboys, or for sterile venting during a slow exhaust/liquid autoclave cycle of EZgrip® carboys.

Dec 22, 2017 · PTFE membranes were used in a significant share of studies in all phases, owing to their high hydrophobicity, thermal and chemical stability. They are more hydrophobic than other materials (e.g., PP and PVDF) and thus are less susceptible to wetting in MD. Most commercial MD installations use PTFE membranes .

United States Patent 4525374. Abstract: A method is described for coating a hydrophobic filter membrane so as to render said membrane hydrophilic. This method is particularly for treating polypropylene or polytetrafluoroethylene in which the filter membrane is contemplated to have a pore size not larger than two (2) microns.

GORE® Turbine Filters meet the filter classification of E12 according EN 1822 and have a minimum efficiency of 99.5% for the MPPS. By contrast, E10 filters capture only 85% of the MPPS. Other non-HEPA filter solutions may only capture 50% or even less. Filter performance ultimately comes down to the inherent characteristics of the filter media.

hydrophobic PTFE membrane is air permeable, but highly resistance to liquid water. The media is pleated to form a cartridge filter that can withstand extreme environmental conditions in the field and the potential burst pressure due to gas turbine upset. An expanded view of the filter construction is shown in Figure 5. Figure 5.

Buy Advantec J100A025A PTFE Hydrophobic Membranes with Support; 25 mm dia; 1.00 µm; 100/PK and more from our comprehensive selection of Advantec Hydrophobic PTFE Membranes with Support

tionally pure compared to other common polyamide (=nylon) filters and competitor products. For this products raw materials are used which do not interfere with standard analytical methods. Our coating-free hydrophobic PTFE membrane used in Minisart ® SRP is suitable for venting applications as well as the leachable