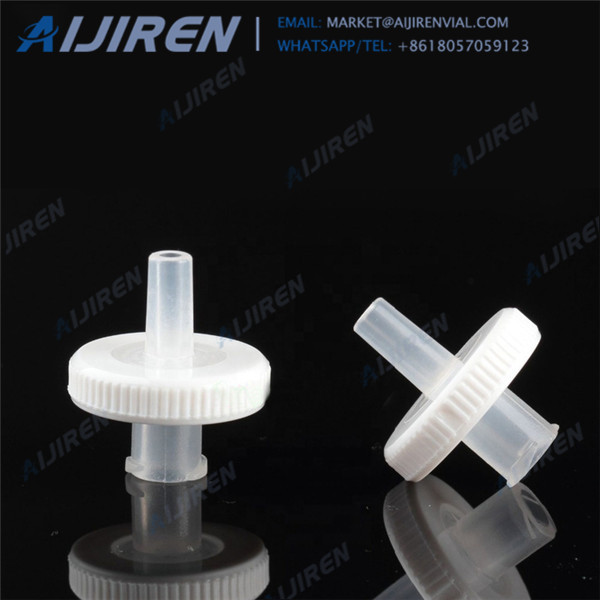

Getting started Ptfe Hollow Fiber Membrane Ptfe Hollow Fiber Membrane - China Manufacturers, Suppliers, Factory We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for Ptfe Hollow Fiber Membrane, Pp Membrane, Sample Detection, 1000pp Membrane Filter Press,Sterile Syringe Filters.

These membranes have been identified as one of the key components for various consumer related applications for fuel cells, e.g. automobiles, back-up power, portable power etc. Due to its application for many consumer markets, the technology keeps on

Find ptfe membrane filter and related products for scientific research at MilliporeSigma Product Number Product Description SDS WHAGN203APEORGSP supplied with single vial compressor, PTFE membrane, pore size 0.2 μm, amber vial color, pack of 100

Read the latest articles of Nano Energy at ScienceDirect.com, Elsevier’s leading platform of peer-reviewed scholarly literature Note that our submission system has recently changed. If you plan to submit to Nano Energy, please click on the Submit your Paper link

2021/5/21 · The PTFE membranes also referred as Polytetrafluoroethylene membranes. These are non-reactive filter media used in various applications that involves acids, bases, solvents, and different liquids. Also, they are used in the industrial applications such as mineral production, temperature, humidity, power generation, and chemical processing to monitor standards for quality of product and

PTFE is the raw material for the PTFE fiberglass and changes in prices of PTFE can hinder the market for PTFE fiberglass. The PTFE fiberglass is employed in various industries such as aerospace, construction & building, power generation, laminates, electric insulation, electronics & telecommunications, heat sealing, screen printing, automotive, and food processing.

Milliseal Membrane Seal, PTFE, 18 mm. Product Number. Product Description. SDS. FWMS01800. This is a 18 mm Hydrophobic PTFE Membrane Filter with a 0.45 micron pore size. For use in Sterilizing filtration, bioassays, solvent filtration.

Step 5: Pre-cooler. The compressed gas leaving the compressor is hot. You want to remove this heat using an ice bath. The pre-cooler is sized to fit into a large bucket. Basically, the precooler is a long coil of tubing. I used 20 feet of 1/4" 304 seamless stainless steel with a 0.035" wall thickness.

It’s clear that PTFE is a very useful, unique product, but in order to establish the winner between Teflon vs PTFE, we need also to consider what Teflon is too. Discovered in 1938, Teflon was developed by the DuPont Co and managed by a spin-off of the company known as Chemours.

Pharmaceutical & Biopharmaceutical. Rigorously compliant to meet the changing needs of our global customers, Gore’s solutions for pharmaceutical and biopharmaceutical manufacturers include a suite of efficient, technology-driven products for single- and multi-use applications. View subcategories. Pharmaceutical & Biopharmaceutical Subcategories.

Polymer electrolyte membrane (PEM) electrolysis is the electrolysis of water in a cell equipped with a solid polymer electrolyte (SPE)[2] that is responsible for the conduction of protons, separation of product gases, and electrical insulation of the electrodes. The PEM electrolyzer was introduced to overcome the issues of partial load, low

Lithium-Sulfur Batteries Lithium sulfur batteries (LiSB) using lithium metal as the anode, an organic liquid electrolyte, and sulfur composite as the cathode, could have a high theoretical capacity (1675mAhg−1) and specific energy (2567Whkg−1). From: Emerging Materials for Energy

2010/5/4 · Microbial Fuel Cells (MFCs) are an emerging technology that uses bacteria to generate electricity from waste. Bacteria in a Microbial Fuel Cell break down our food and bodily wastes, effectively generating power from the materials that are usually thrown away. By tapping into this previously unharnessed source of power, clean, sustainable

Microelectronics is one of the many industries we serve at Pall Corporation. Our microelectronics filtration systems work to reduce the cost, increase reliability, and maximize the

This directs the water flow through the anode material, and this can be another option to increase the power generation in a MFC. This was also confirmed in a study conducted by Cheng et al. [74