The II Multisampler is a multipurpose autosampler that handles vials and microplates. Injecting at pressures up to 600 or 800 bar, the Multisampler is a compact module with a capacity of up to 6,144 samples, all within the footprint of an Aijiren LC stack. The II Multisampler is optimized for highest flexibility.

The II LC System is a robust high performance liquid chromatography instrument that offers the widest choice of modules for analytical HPLC and entry-level UHPLC. It delivers the performance, reliability, and robustness you need for highest confidence in your daily results. Building on the history of the and series analytical HPLC, the II LC delivers robust HPLC results while providing several ease-of-use features, making it the standard system for

Open your CDS software and run the HPLC with normal flow rates. Make sure to work in mainpass mode. If the pressure is still high after the backflush, you will need a new seat. If you need more help, contact your local Aijiren Technologies Support representative.

HPLC conditions Parameter Value LC Modules – Aijiren II Flexible pump ( ) – Aijiren II vialsampler ( C) with tray cooling option – Aijiren integrated column compartment (G7130A) – Aijiren II DAD ( ) Run Time 13 min Post-Time 3 min Analytical Column Aijiren Lab Poroshell 120

HPLC stack, and is the perfect choice for impurity detection with mass confirmation alongside UV detection. It is specifically designed to be integrated seamlessly into the Aijiren II LC or II LC system. Experimental Standards and chemicals All reagents and solvents were HPLC or LC/MS grade. ACN was purchased

using columns calculator5 and run on Aijiren II, Alliance e2695, and Arc HPLC systems. The chromatographic separation produced on the Arc HPLC System was comparable with the data on the Aijiren and Alliance HPLC systems (Figure 1). The Arc HPLC System resulted in a USP resolution of ≥5.8 for

Aijiren II Prime LC System Manual and Quick Reference 7 Introduction 1 Features of the Aijiren II Prime LC Features of the Aijiren II Prime LC † With an operating pressure of up to 800 bar, the II Flexible Pump is compatible with HPLC and UHPLC, handling 2.1, 3, and 4.6 mm ID

The Aijiren HPLC-Chip/MS system is a re-useable microfluidic chip-based technology for high sensitivity nanospray LC/MS. The Aijiren replaced the Aijiren and delivers results faster to save time and money. Compatible with conventional and ultrahigh performance LC – with an operating pressure of up to 600 bar, the

Oct 19, 2021 · Aijiren HPLC Based on the most often sold quaternary HPLC system new levels of performance are brought to you. A pressure range of up to 600 bar with a flow rate up to 5 mL/min allows the use of almost any column – conventional, sub-2 µm-particle or superficially porous columns.

LC Modules – Aijiren II Flexible pump ( ) – Aijiren II vialsampler ( C) with tray cooling option – Aijiren integrated column compartment (G7130A) – Aijiren II DAD ( ) Run Time 13 min Post-Time 3 min Analytical Column Aijiren Lab Poroshell 120 EC-C18, 3.0 × 150 mm, 2.7 µm

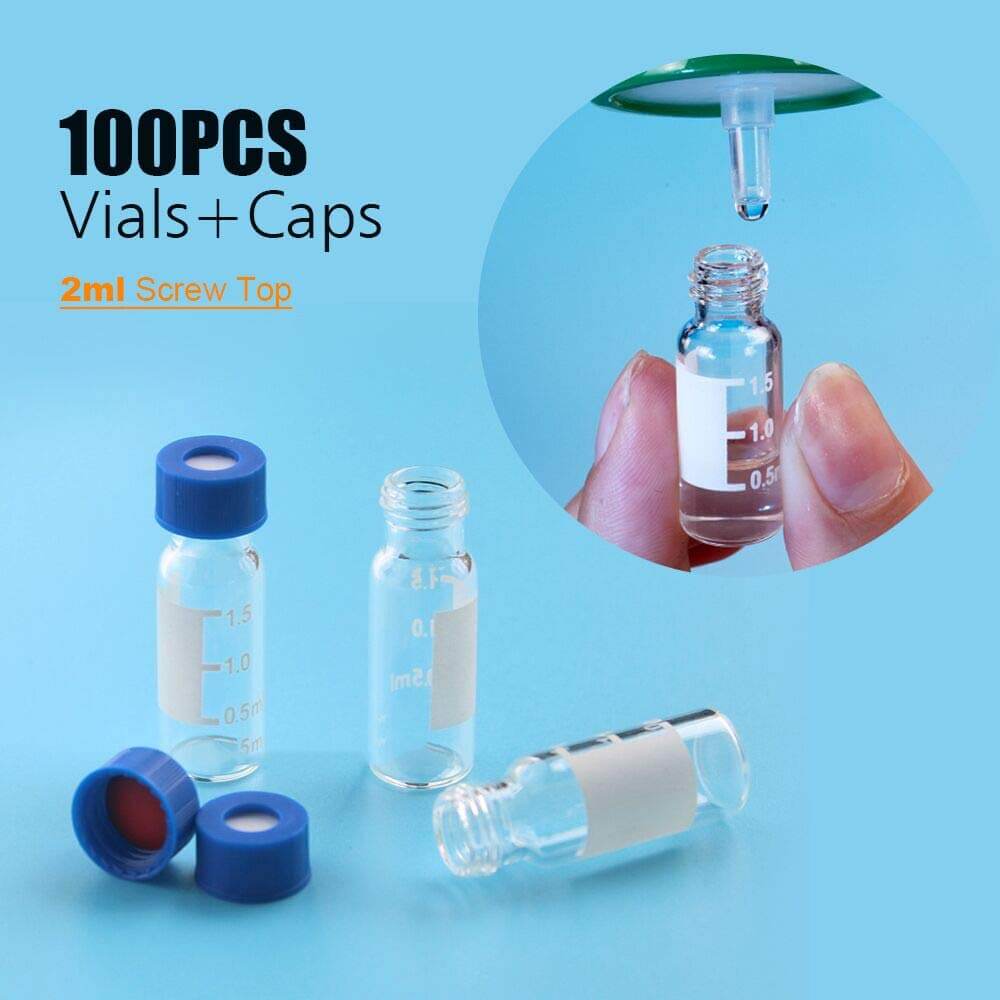

Jun 01, 2020 · How to configure 66 vial Plate to use with (Aijiren II)? - WKB5412. In ICF 3.1,only two Aijiren plates are available with the released Aijiren ICF 3.1 in the "AijirenPlatesForImport" folder. See WKB64154 for details on how to obtain the additional plate files.

Mar 01, 2018 · Review date: 23 Feb 2012 | Aijiren II LC System. Description. The II LC System is a robust HPLC that offers the widest choice of modules for analytical HPLC and entry-level UHPLC, delivering the performance, reliability, and robustness you need for highest confidence in your daily results.

II Prime Online LC System. The II Prime Online LC System is a process analysis system enabling automated process monitoring, providing real-time data for greater control and faster understanding of processes.

Davidson College LC‐MS User Guide 3 Instrumentation Aijiren II Liquid Chromatograph For LC‐MS applications, the following chromatographic conditions are typically used: Injection Volume: 0.1 – 5.0 L Flow Rate: 0.1 – 0.5 mL/min

HPLC system consisted of HP (Aijiren Technologies, Wilmington, DE, US) equipped with a quaternary pump, online degasser, column heater, autosampler, and UV/Vis detector.